Bus-controlled pneumatic conveying gulp valve and control system

A technology of pneumatic conveying and bus control, applied in the direction of control valve, valve details, valve device, etc., which can solve the problems such as the inability to monitor the instantaneous pressure field of the pipeline pressure pipeline in real time, the inability to distinguish damaged equipment for maintenance, and the inability to monitor the valve status in real time. , to achieve the effect of flexible and changeable control methods, visualization of valve status, and convenient repair and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

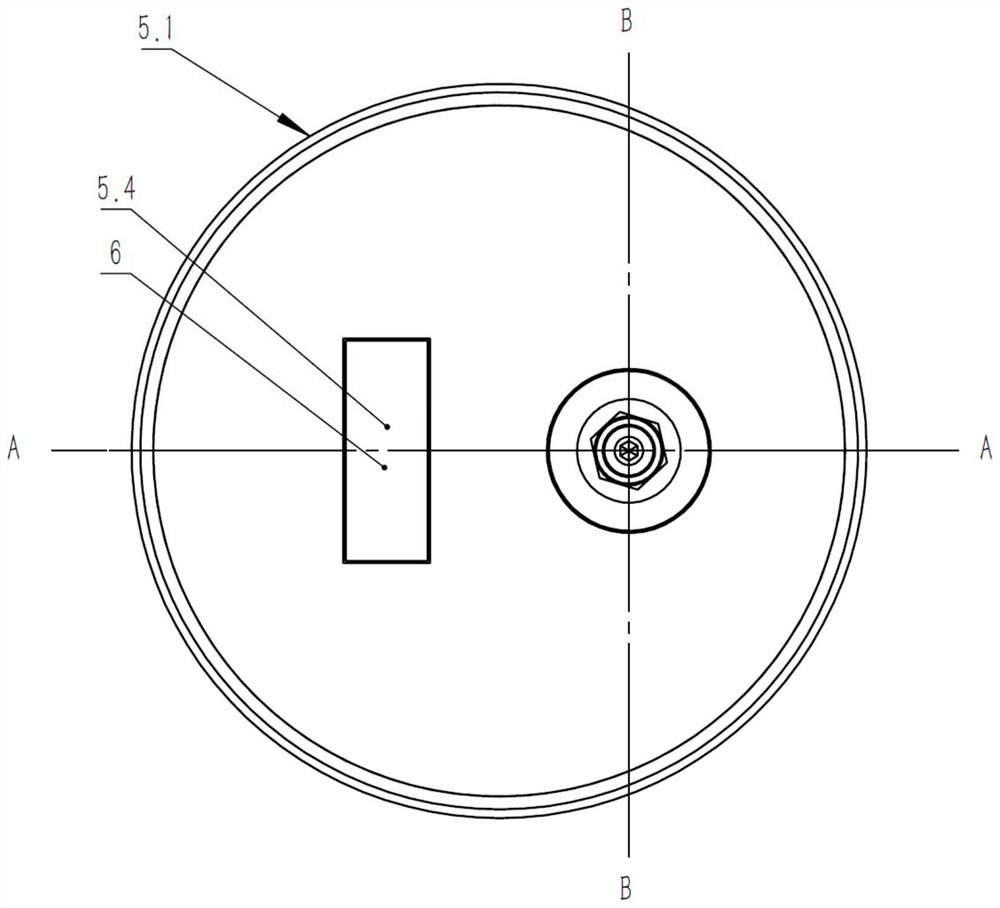

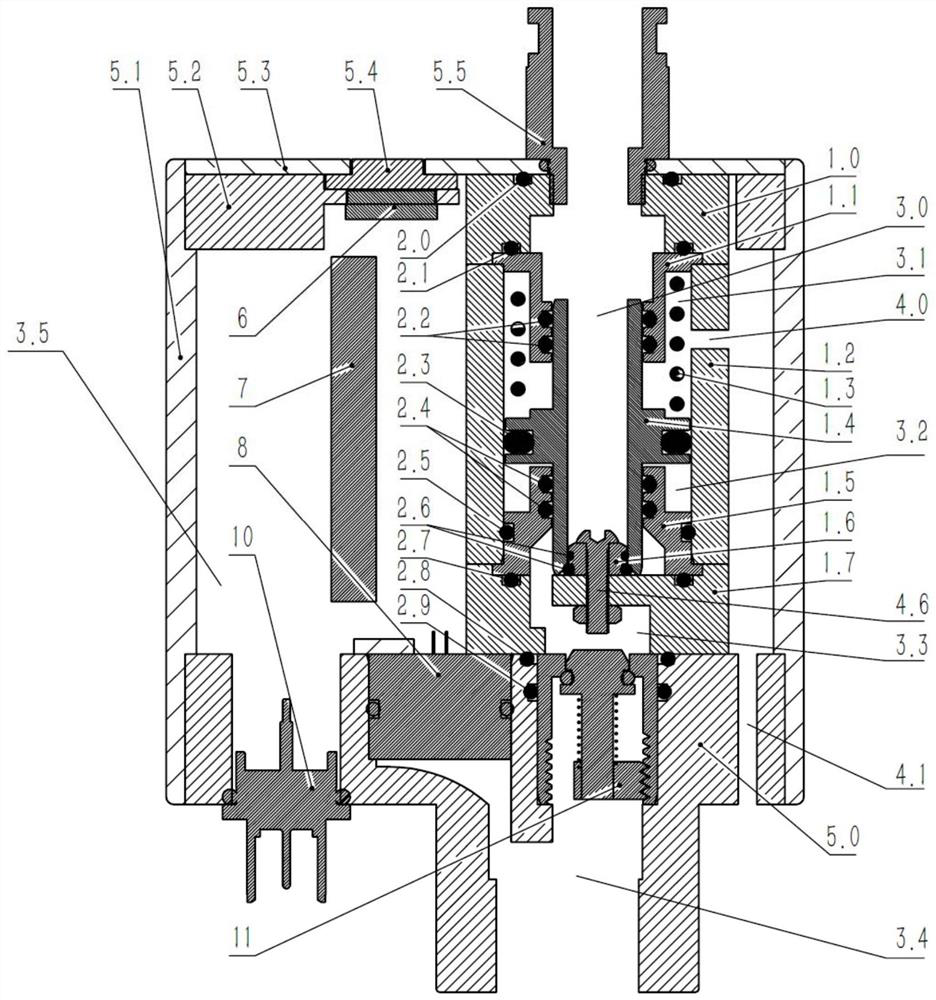

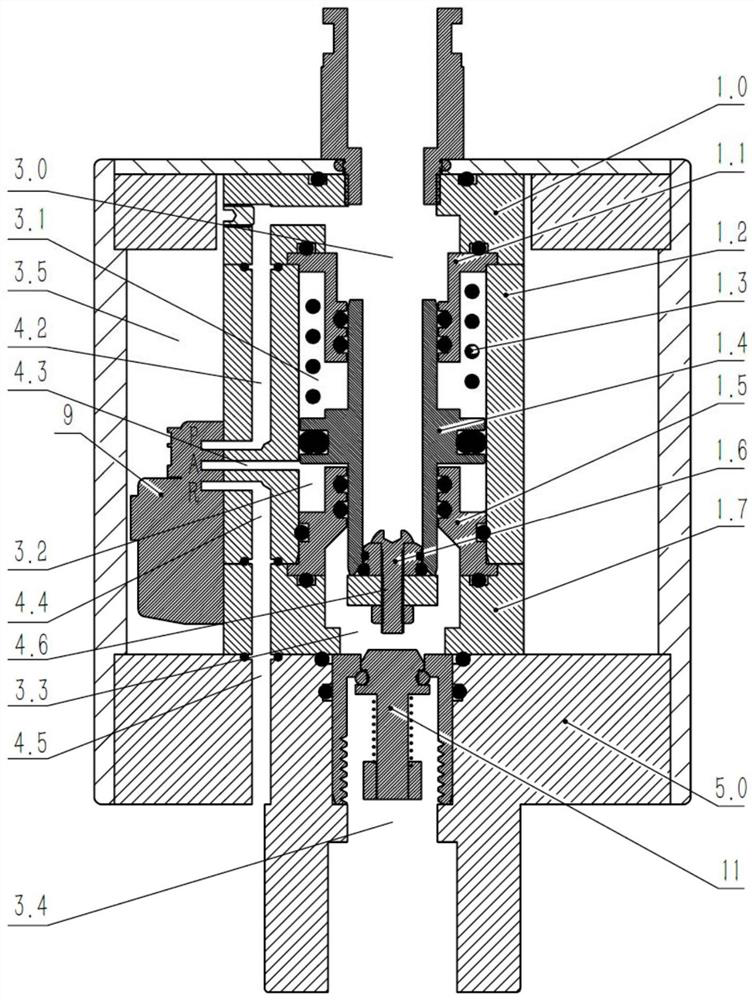

[0027] refer to figure 2 , image 3 As shown, a bus-controlled pneumatic delivery valve 20 includes a valve body, a base 5.0, a housing 5.1, a display screen 6, a central control unit 7, a pressure core 8, and a miniature solenoid valve 9;

[0028] refer to figure 2 As shown, the valve body is arranged on the base 5.0, the housing 5.1 is arranged on the base 5.0, and the upper opening cover of the housing 5.1 is provided with a top plate 5.2, and a top panel 5.3 is fixedly arranged on the top plate, so that the inside of the housing 5.1 forms a shell The inner cavity 3.5, the valve body is arranged on the base 5.0, the upper part of the valve body is connected with the inlet pipe joint 5.5, and the lower part of the base 5.0 is provided with the outlet cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com