A heat-pressing mechanism for brake pads with heat dissipation and drainage grooves and its implementation method

A heat-pressing mechanism and brake pad technology, which is applied to home appliances, other home appliances, household components, etc., can solve the problems of unfavorable use cost for small and medium-sized enterprises, slow production time cycle, heavy workload of employees, etc., and achieve flexible use Improvement of performance, reduction of equipment cost, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

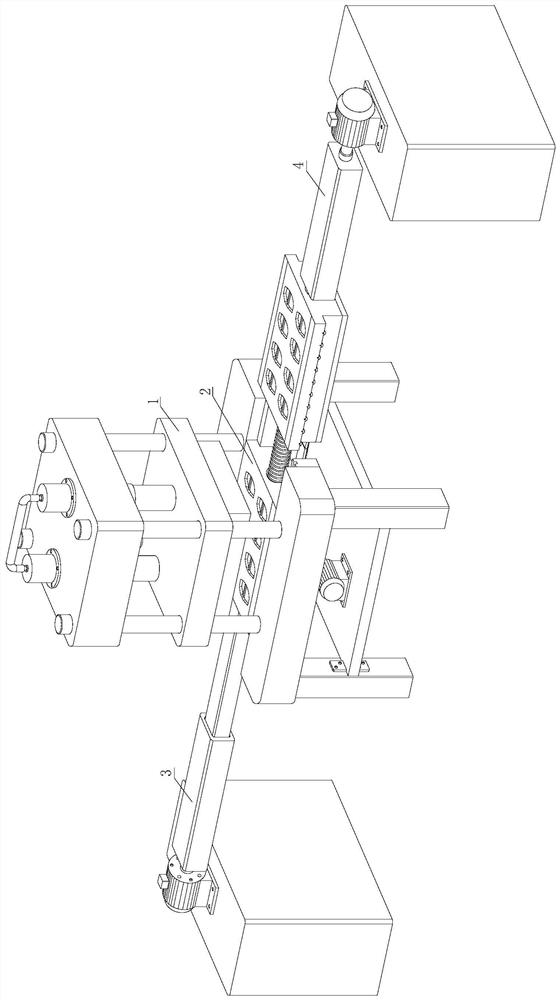

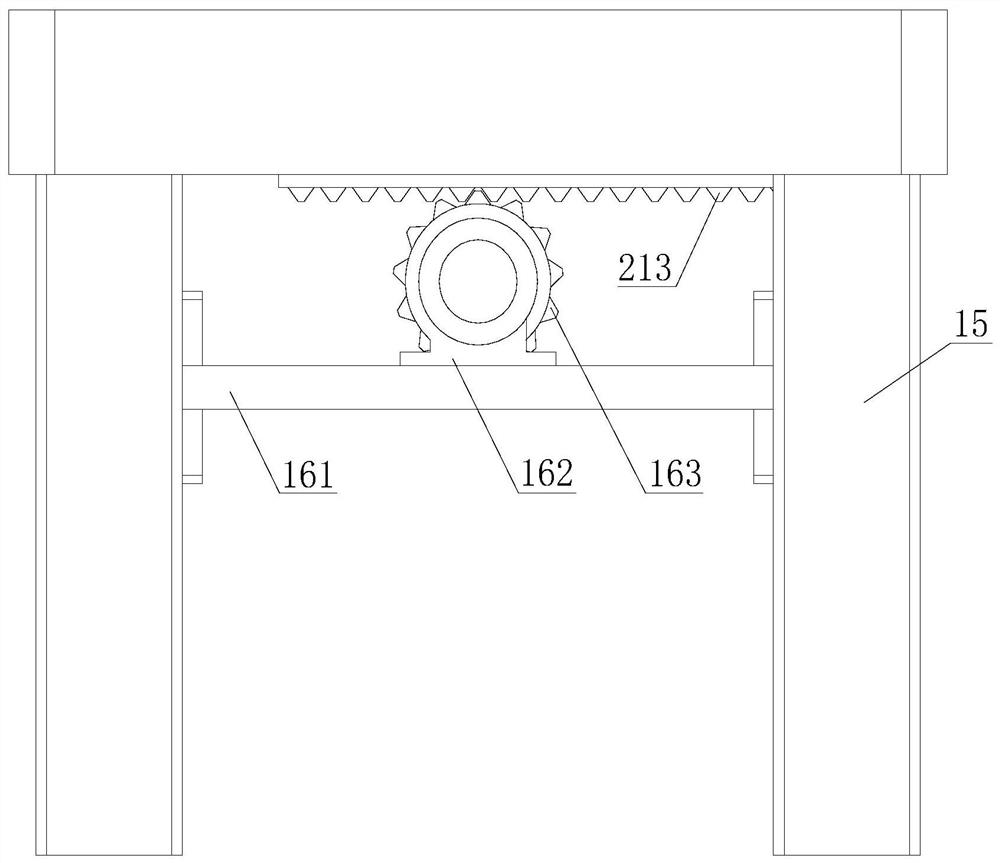

[0035] see Figure 1-2 , a brake pad hot-pressing mechanism with a heat-dissipating drainage groove, including a hot-pressing host 1, a lower die assembly 2, a first rotating mechanism 3 and a second rotating mechanism 4, and the lower die assembly 2 is arranged in the hot-pressing host 1, one end of the first rotating mechanism 3 is connected to one end of the lower die assembly 2, one end of the second rotating mechanism 4 is connected to the other end of the lower die assembly 2, and the hot pressing host 1 includes a support frame 11, Hydraulic cylinder 12 , stabilization plate 13 , upper die 14 , support table 15 and moving assembly 16 , the support frame 11 is installed on the upper end of the support table 15 , the hydraulic cylinder 12 penetrates the upper end of the support frame 11 and is connected to the upper end of the stabilization plate 13 to stabilize The four corners of the plate 13 are movably connected with the support frame 11 , the upper die 14 is arranged...

Embodiment approach

[0040] In order to better show the hot-pressing process of the brake pad, the present embodiment now proposes a method for implementing a hot-pressing mechanism for a brake pad with a heat-dissipating drainage groove, including the following steps:

[0041] Step 1: Pour the raw materials into the first lower die 21 in sequence, the first drive motor 162 is started in a forward motion, and the first lower die 21 is transported to the lower end of the upper die 14;

[0042] Step 2: At this time, the hydraulic cylinder 12 is activated, the upper die 14 is moved downward, the hot pressing of the brake pads is started, and the raw materials are put into the second lower die 23 at the same time;

[0043] Step 3: After the hot pressing time, the upper die 14 moves upward, the first driving motor 162 is reversed and started, the first lower die 21 is sent out, and the second lower die 23 is sent in.

Embodiment 2

[0045] see Figure 1-2 , a brake pad hot-pressing mechanism with a heat-dissipating drainage groove, including a hot-pressing host 1, a lower die assembly 2, a first rotating mechanism 3 and a second rotating mechanism 4, and the lower die assembly 2 is arranged in the hot-pressing host 1, one end of the first rotating mechanism 3 is connected to one end of the lower die assembly 2, one end of the second rotating mechanism 4 is connected to the other end of the lower die assembly 2, and the hot pressing host 1 includes a support frame 11, Hydraulic cylinder 12 , stabilization plate 13 , upper die 14 , support table 15 and moving assembly 16 , the support frame 11 is installed on the upper end of the support table 15 , the hydraulic cylinder 12 penetrates the upper end of the support frame 11 and is connected to the upper end of the stabilization plate 13 to stabilize The four corners of the plate 13 are movably connected with the support frame 11 , the upper die 14 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com