Stainless steel pipe clamping and pressing type connector machining device and machining method

A stainless steel pipe and processing equipment technology, applied in the field of pipe fittings processing, can solve the problems of large loss of polyurethane glue, high cost, scrap rate, etc., achieve good sealing performance, stable processing process, and ensure the effect of fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

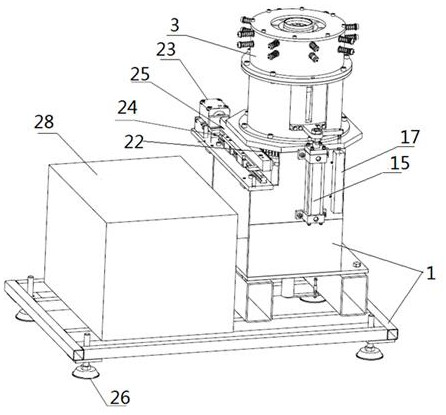

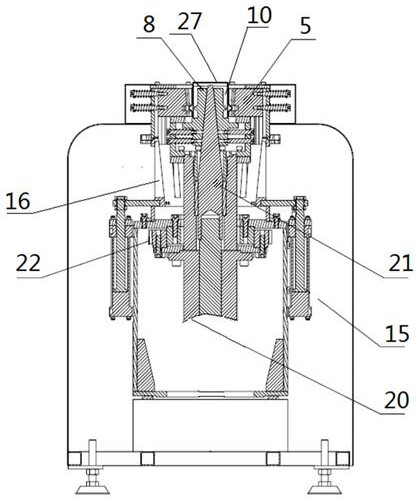

[0028] The following is attached figure 1 to attach Figure 7 The principles and features of the invention are described, and the examples given are only used to explain the invention, not to limit the scope of the invention.

[0029] A stainless steel pipe clamping type interface processing equipment, comprising a frame 1, an inner mold assembly 2 and an outer mold assembly 3, the outer mold assembly 3 is fixedly connected to the frame 1, the inner mold assembly 2 is connected to the The frame 1 is connected in rotation, and the inner mold assembly 2 and the outer mold assembly 3 are relatively rotatable.

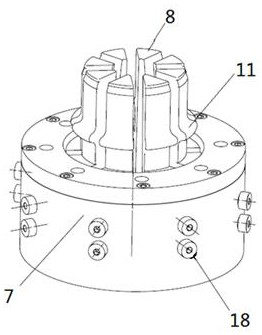

[0030] The outer mold assembly 3 includes an outer cylinder 4 , several outer templates 5 , a first connecting rod 13 and a first spring 14 . A plurality of the outer templates 5 enclose each other to form a cylindrical structure with a first cavity 6 , and the outer templates 5 are arranged in the outer cylinder 4 and slide along the radial direction of the outer cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com