A high precision pt200 high temperature sensor

A high-temperature, sensor technology, applied in thermometers, thermometer parts, thermometers with direct heat-sensitive electric/magnetic elements, etc., can solve the problems of low accuracy, temperature measurement lag, and control of production and emissions. problem, to achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

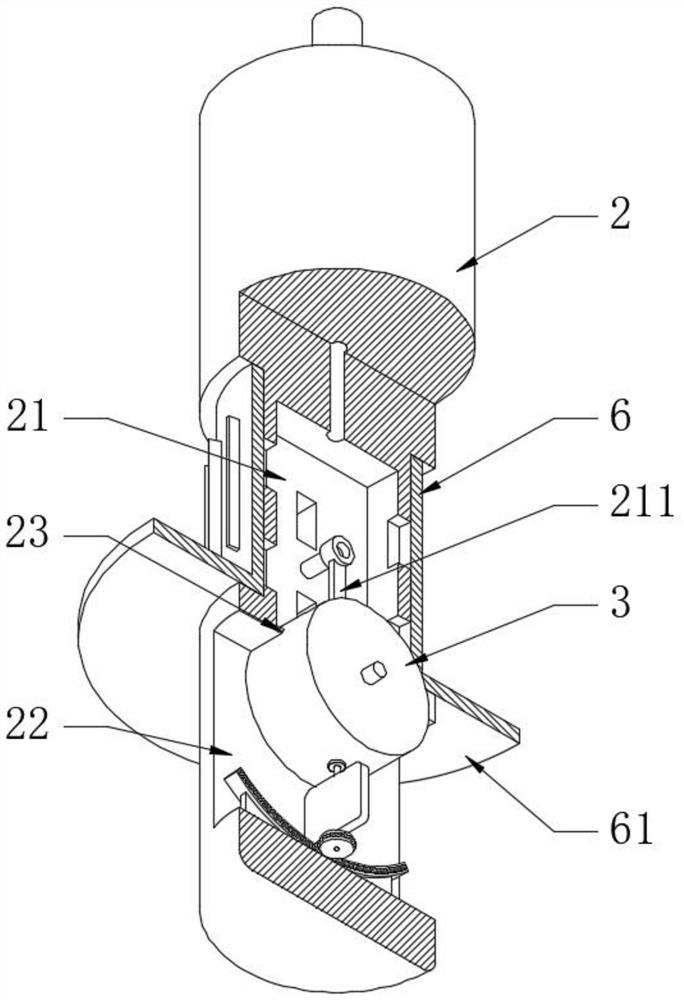

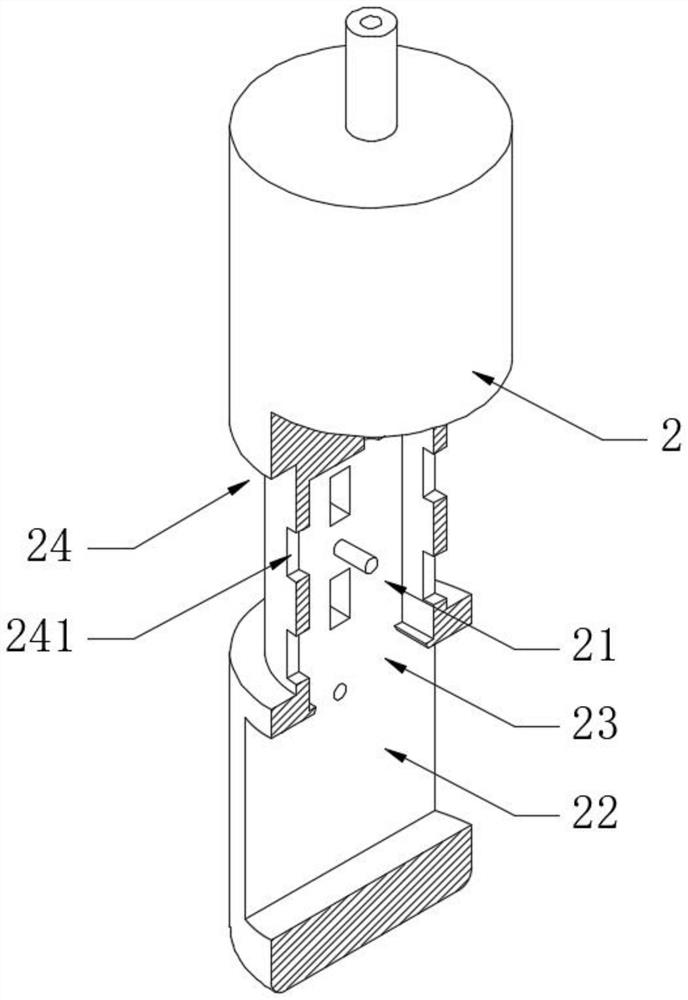

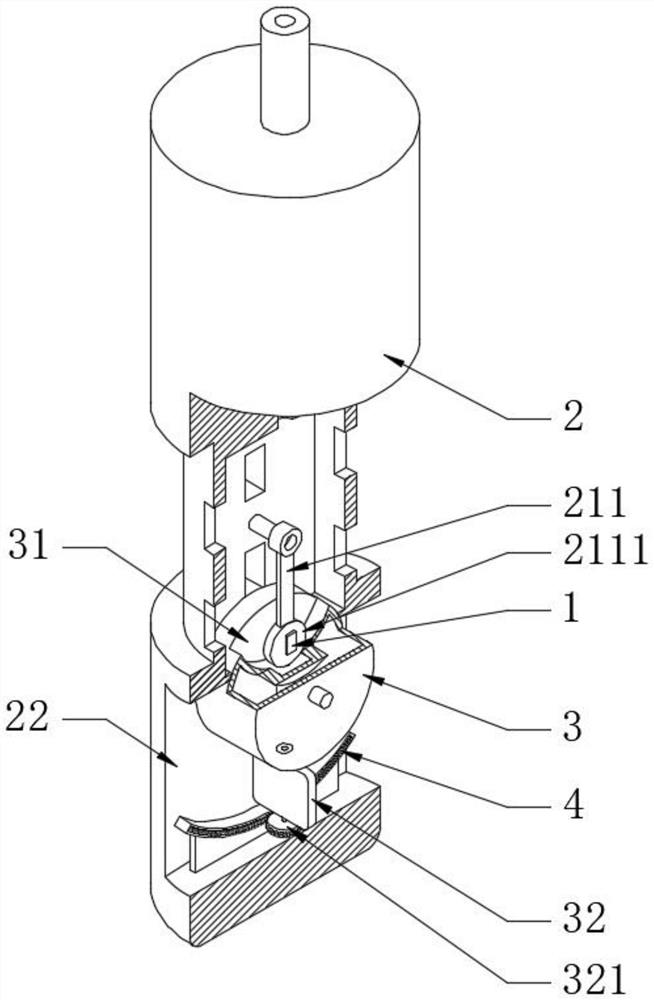

[0029] see Figure 1-3 , a high-precision PT200 high temperature sensor, including a thermistor 1 and a detection rod 2, the detection rod 2 is provided with a resistance chamber 21 with a heat dissipation function, specifically, a section of connected resistance chamber 21 is provided on the outer periphery of the detection rod 2 The ring-shaped sinking groove 24, the bottom of the ring-shaped sinking groove 24 is provided with a heat conduction hole 241 connected to the resistance chamber 21, and the ring-shaped sinking groove 24 is provided with a heat dissipation pipe 6. By setting the heat dissipation pipe 6, it is convenient to reduce the high temperature in the resistance chamber 21 discharge, to avoid residual temperature affecting the extraction of temperature, and the outer periphery of the heat dissipation pipe 6 is fixedly provided with a mounting seat plate 61, and a hole can be opened on the mounting seat plate 61 or a threaded sleeve can be provided. The mountin...

Embodiment 2

[0031] see Figure 4 The difference from Example 1 is that the outer wall of the heat-resistance plate 3 is fixedly provided with a heat-conducting shaft 5 that is rotatably connected to the middle of the wind-resistance plate 32, and the heat-resistance plate 3 is provided with a heat-insulating sleeve 33 coaxially distributed with the heat-conducting shaft 5 , the heat conduction shaft 5 can conduct the temperature in the exhaust gas channel 22 to the resistance cavity 21, one end of the heat insulation sleeve 33 extends into the groove 31, and the other end is fixedly connected with the heat conduction shaft 5, this setting is suitable for the exhaust gas with a low flow rate Environment, suitable for the environment with stable exhaust gas temperature.

[0032] Working principle: Before use, connect the thermistor 1 electrically to the signal conversion circuit, then insert one end of the exhaust duct 22 on the detection rod 2 into the exhaust pipe, and then fix it by inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com