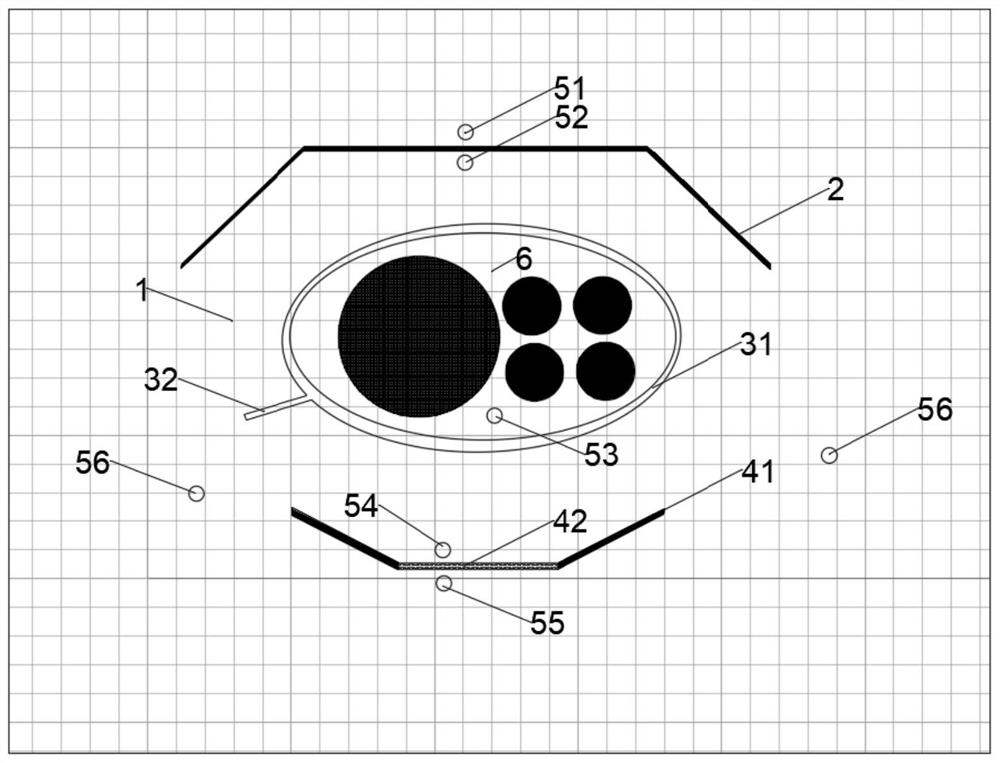

In-service industrial site pollution comprehensive management and control system and method

A control system and site technology, applied in the sewer system, waterway system, infrastructure engineering, etc., can solve the problems of immobility, lack of prevention and control measures, weak ability to intercept and remove pollution plumes, etc., and achieve the effect of increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0087] The area where a large-scale tank farm of an enterprise is located is relatively flat, and there are detailed hydrogeological data in the early stage. According to relevant information, the Quaternary loose soil layer in the plant area is divided into miscellaneous fill (1-3m), silt sandy layer (5-14m), silty clay layer (8-20m), and the silt sandy layer is the underground water layer The main distribution area contains silt, silt and fine sand, and the permeability coefficient is about 2.2×10 -5 cm / s, the overall hydraulic gradient is 0.0004; the clay layer constitutes the first water-resisting layer, and the permeability coefficients are all lower than 10 -6 cm / s. The groundwater level is buried at a depth of 3-5m, and the groundwater flow field in the submerged layer of the plant area is single and uniform, flowing from northwest to southeast. There is no watershed and hydrological boundary inside. The first water-resisting layer is buried at a depth of 8-12m. During...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com