An optimized anti-shock protection structure for ships based on aluminum honeycomb

A protective structure, aluminum honeycomb technology, applied in the direction of hull, anti-collision, ship construction, etc., can solve the problems of ship impact environment, damage to the overall structure of the breach, ship board structure shipboard equipment and shipboard personnel threats, etc. , to achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

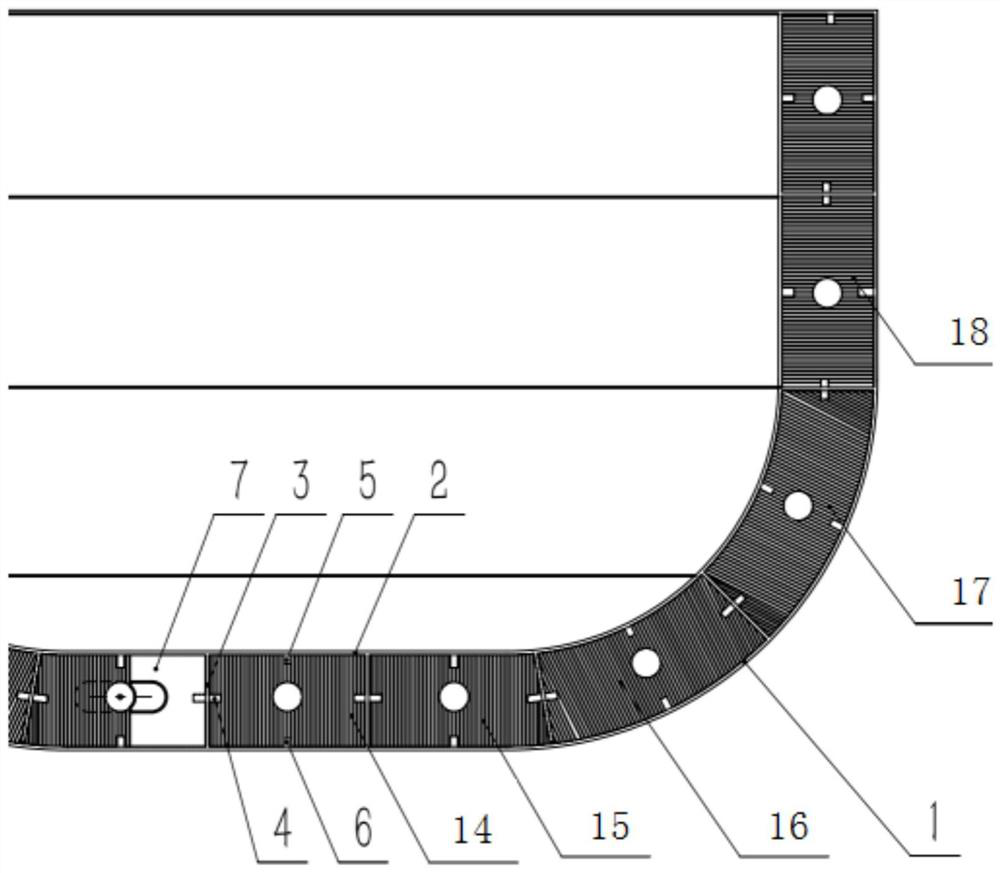

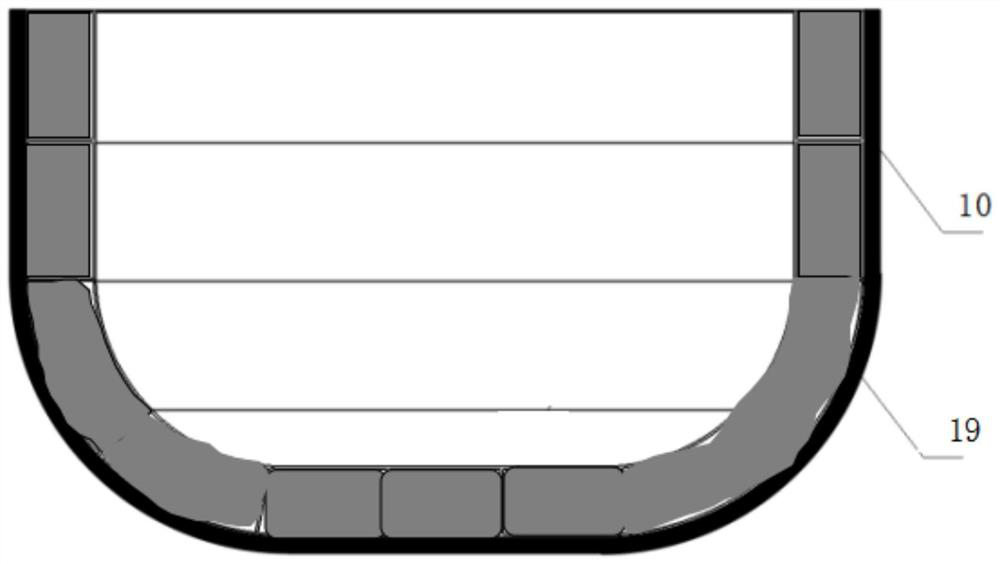

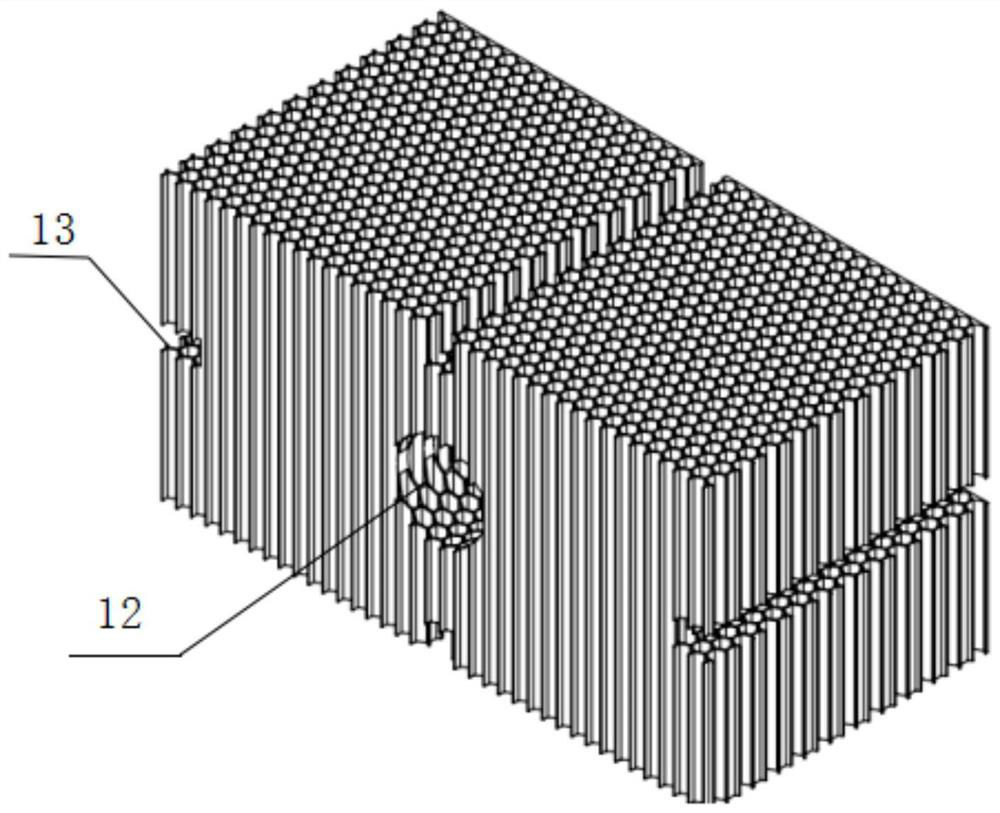

[0032] Such as Figure 1-Figure 6 As shown, a ship anti-shock protection structure based on aluminum honeycomb optimization, including hull outer plate 1, hull inner plate 2, hull girder 3, hull solid floor plate 7 and inner protective structure, said hull outer plate 1 , hull inner plate 2, hull girder 3 and hull solid floor 7 encircle a plurality of small cabins, and the described inner protection structure is filled in a plurality of small cabins;

[0033] A number of hull longitudinal stiffeners 6 are evenly arranged on the outer hull plate 1, a number of hull longitudinal stiffeners 5 are uniformly arranged on the hull inner plating 2, and hull girder reinforcements are arranged on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com