Color film substrate and manufacturing method thereof

A technology of color film substrate and manufacturing method, which is applied in nonlinear optics, instruments, optics, etc., can solve problems such as color shift or reflection, and achieve the effect of eliminating damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

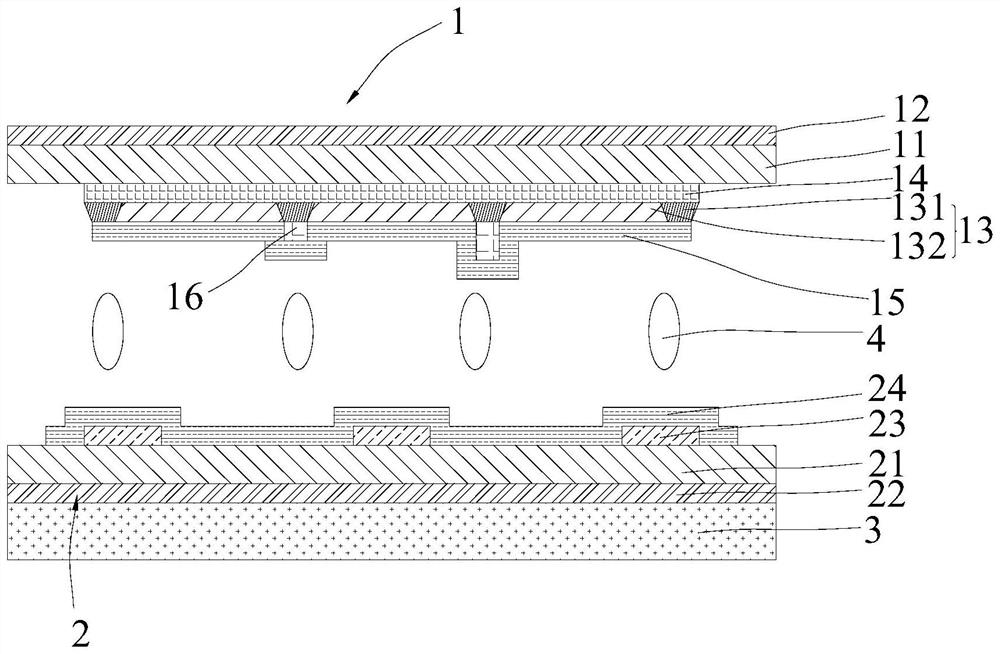

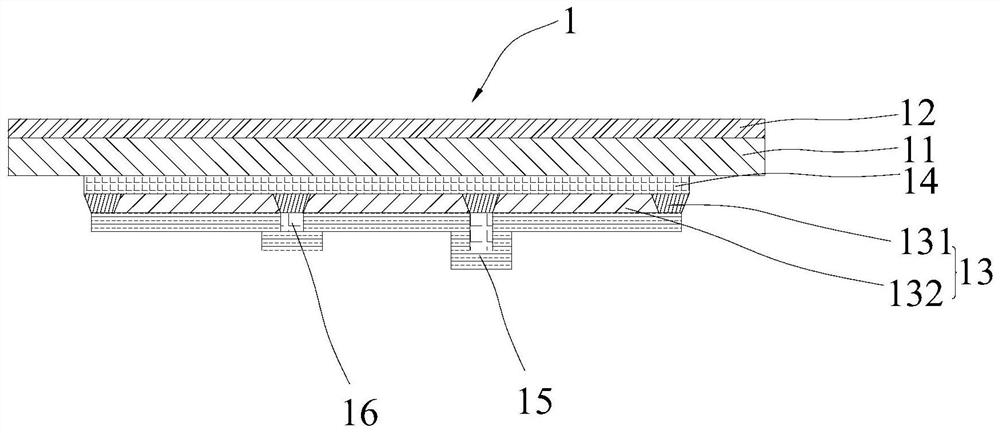

[0040] Further, see figure 2 , the color filter substrate 1 further includes a blue light absorbing film 14 , and the blue light absorbing film 14 is disposed between the first base substrate 11 and the color filter layer 13 . The blue light absorbing film 14 can effectively filter out high-energy short-wave blue light between 400nm and 450nm, while maintaining a high transmittance for light of other wavelengths, so the pattern synthesized by the color filter layer 13 passes through the Filtering can reduce or eliminate the damage caused by blue light to human eyes.

[0041] It should be noted that the first base substrate 11 is usually made of alkali-free glass, but it inevitably contains Na+, K+, Mg2+ plasma, and the blue light absorbing film 14 is used as the base of the color filter layer 13 to block the first substrate. The metal ions in the base substrate 11 diffuse into the color filter layer 13, further blocking the diffusion of the metal ions in the first base subst...

Embodiment 2

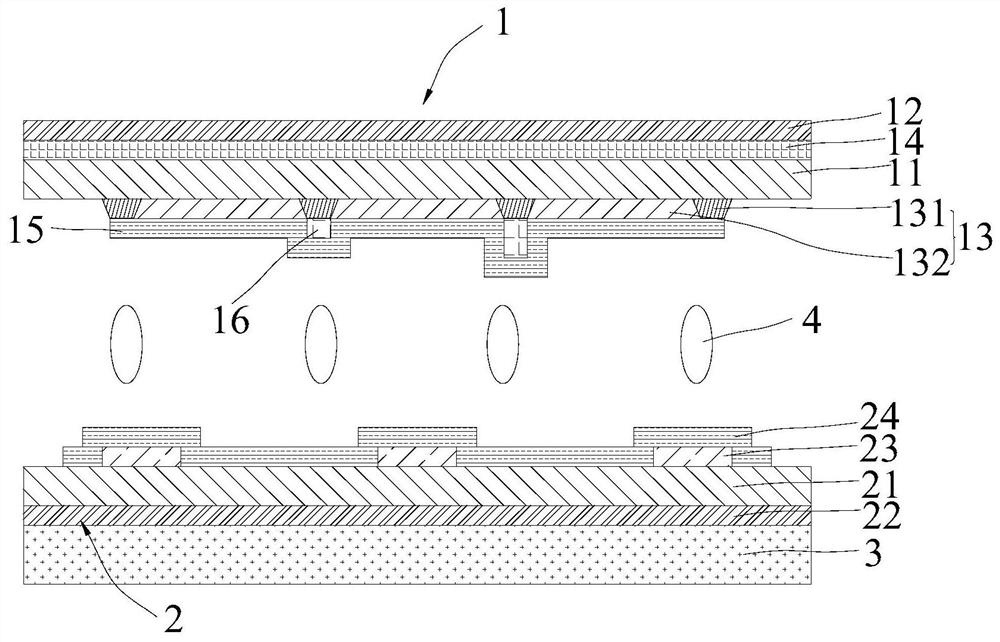

[0044] further combined Figure 4 , the blue light absorbing film 14 is disposed between the first base substrate 11 and the first polarizer 12, the blue light absorbing film 14 can effectively filter out the high-energy short-wave blue light between 400nm-450nm, while maintaining the Due to the high transmittance, the patterns synthesized by the color filter layer 13 are filtered when they reach human eyes, which can reduce or eliminate the damage caused by blue light to human eyes.

[0045] It should be noted that, in this embodiment, firstly, the material of the blue light absorbing film 14 is a transparent organic resin, which is hydrophobic and has excellent optical stability and thermal stability, and this material is used as the first base substrate 11 and The base layer between the first polarizers 12 can enhance the adhesion of the first polarizers 12, while protecting the triacetyl cellulose (TAC, Triacetyl Cellulose) inside the first polarizers 12, triacetyl cellulo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| yellowness index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com