Operation method for preventing crystal bar from falling and crystal growing furnace with clamping device for preventing crystal bar from falling

A technology of a crystal growth furnace and a clamping device, applied in the mechanical field, can solve problems such as silicon leakage, and achieve the effects of reducing potential safety hazards, facilitating promotion, and solving serious property losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

[0024] as the picture shows,

[0025] An operation method for preventing crystal rods from falling, comprising the following steps

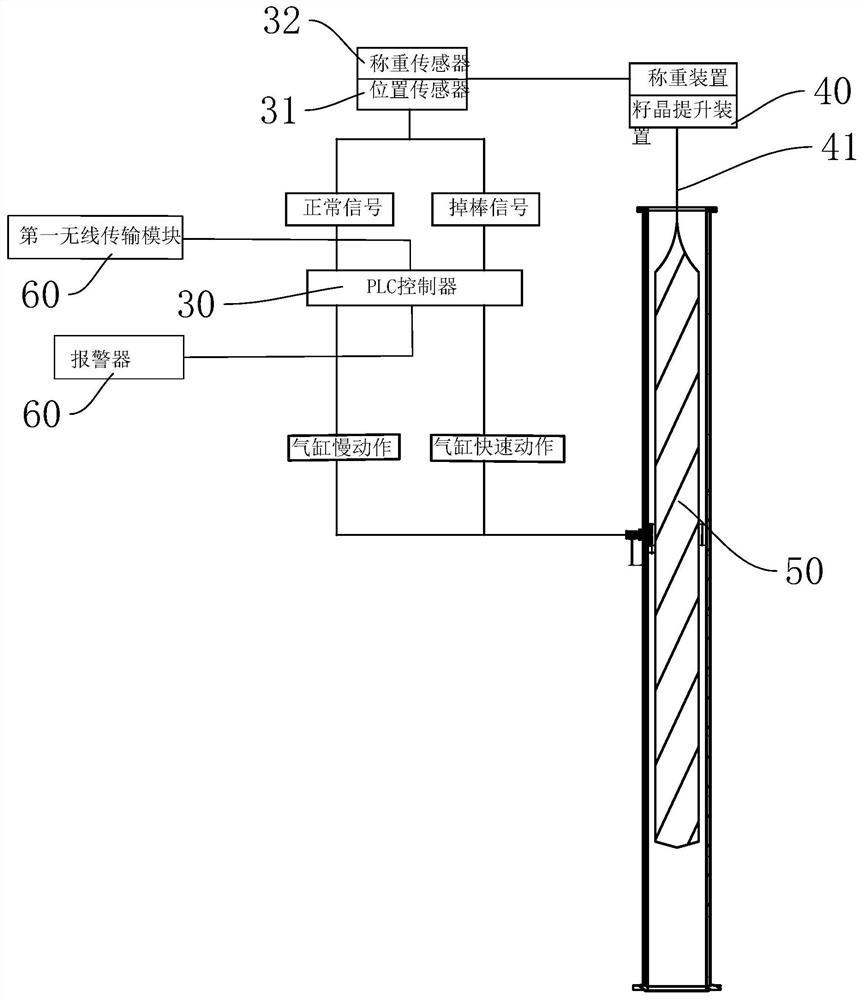

[0026] When the S1 monocrystalline silicon rod breaks from the seed crystal or the seed crystal rope 41 in the auxiliary chamber, the load cell and the position sensor double detect the drop signal of the single crystal silicon rod, and the PLC sends a clamping action signal;

[0027] S2 The clamping device 20 for preventing crystal ingot from falling can be activated instantly and clamp the crystal ingot 50 .

[0028] The crystal growth furnace with a clamping device for preventing crystal rods from falling includes:

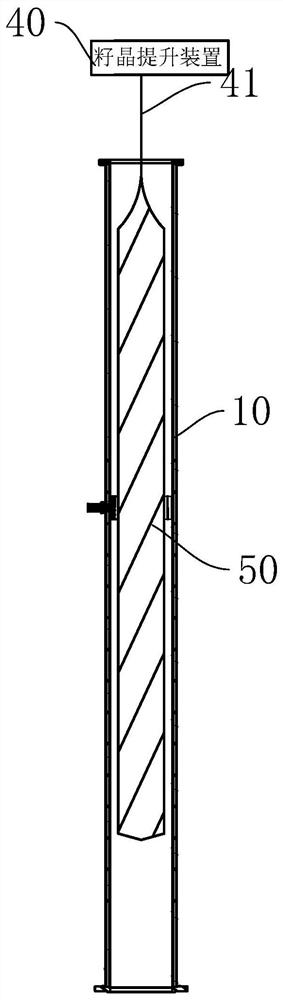

[0029] Upper furnace body 10 or isolation valve;

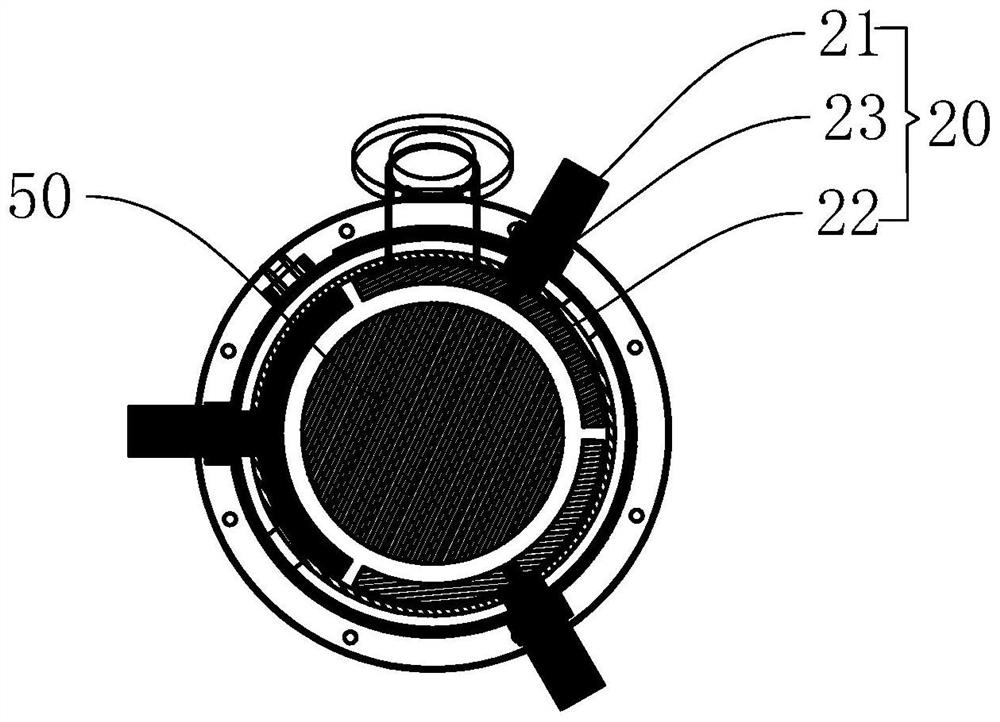

[0030] Anti-crystal ingot drop clamping device 20, a number of anti-crystal ingot drop clamping devices 20 are evenly arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com