Clothes fragrance retaining bead and preparation method thereof

A technology for fragrance beads and clothing, which is applied in the direction of washing composition fragrances, chemical instruments and methods, detergent compositions, etc. It can solve the problems of poor use effect, weak clothing fragrance retention, and insufficient fragrance retention time, and achieve long-lasting Effective adhesion, long-lasting fragrance, and improved comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

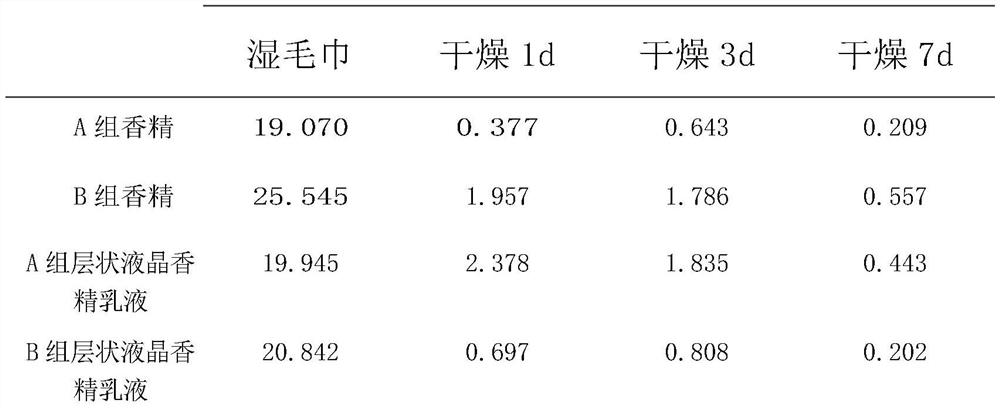

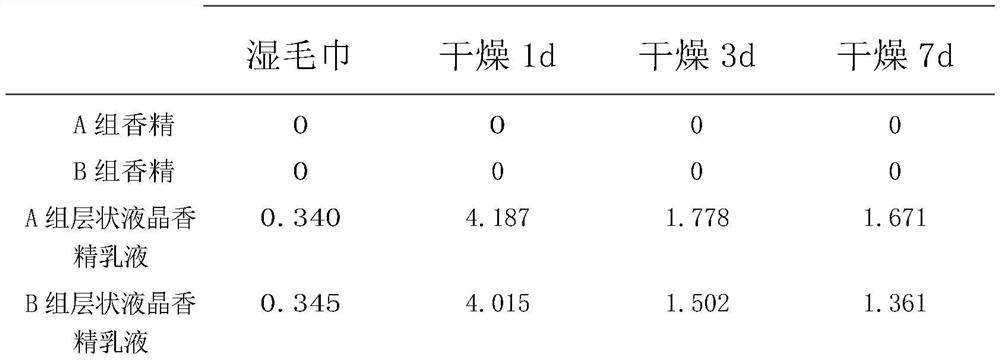

Embodiment 1

[0021] Embodiment 1: The fragrance-retaining beads composition consists of the following components and their weight fractions: 75 parts of polyethylene glycol polymers, and the polyethylene glycol polymers are polyethylene glycol PEG-8000. In the preparation process, the cationic surfactant dimethyl diallyl ammonium chloride or methacryloyloxyethyl trimethyl ammonium chloride is mixed with calcium stearoyl lactylate to effectively avoid stearoyl lactic acid The effect of calcium on the attachment of essence makes the essence adhere to the clothes more effectively for a long time, and the fragrance lasts longer. 3 parts of sodium bicarbonate, 3 parts of glycerin, 4 parts of lamellar liquid crystal essence emulsion, which is composed of essence, emulsification Preservative and stearyl alcohol are made according to the weight ratio of 1.1:1:1. The essence is made of alkyl esters, alkyl alcohols, alkyl ketones, aromatic esters, aromatic alcohols, and aromatic ketones in equal prop...

Embodiment 2

[0027] Embodiment 2: The fragrance-retaining beads composition consists of the following components and their weight fractions: 80 parts of polyethylene glycol polymers, polyethylene glycol PEG-8000, 3-8 parts of sodium bicarbonate , 5 parts of glycerin, 5 parts of layered liquid crystal flavor emulsion, through the preparation process of clothing fragrance beads of the present invention, the cationic surfactant dimethyl diallyl ammonium chloride or methacryloyloxyethyl trimethyl The mixed treatment of ammonium chloride and calcium stearoyl lactylate effectively avoids the influence of calcium stearoyl lactylate on the adhesion of fragrance, so that the fragrance can adhere to the clothes for a long time and effectively, and the fragrance lasts longer. The lamellar liquid crystal fragrance emulsion is composed of fragrance , emulsifier and stearyl alcohol are made according to the weight ratio of 1.1:1:1, and the essence is made up of alkyl esters, alkyl alcohols, alkyl ketones...

Embodiment 3

[0033]Embodiment 3: The fragrance-retaining beads composition consists of the following components and their weight fractions: 85 parts of polyethylene glycol polymers, the polyethylene glycol polymers are polyethylene glycol PEG-8000, 8 parts of sodium bicarbonate, glycerin 7 parts, 7 parts of lamellar liquid crystal fragrance emulsion, lamellar liquid crystal fragrance emulsion is made of fragrance, emulsifier and stearyl alcohol according to the weight ratio of 1.1:1:1, and the fragrance is made of alkyl ester, alkyl alcohol and alkyl ketone , aromatic esters, aromatic alcohols, and aromatic ketones are configured in equal proportions by weight. During the preparation process of the fragrance beads for clothing of the present invention, the cationic surfactant dimethyl diallyl ammonium chloride or methacryloxy Ethyltrimethylammonium chloride is mixed with calcium stearoyl lactylate to effectively avoid the influence of calcium stearoyl lactylate on the adhesion of fragrance,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com