Production process of etched two-color decorative metal plate

A production process, metal plate technology, applied in metal material coating process, decorative art, process for producing decorative surface effects, etc., can solve problems such as difficult to repair, easy to be scratched, single color, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

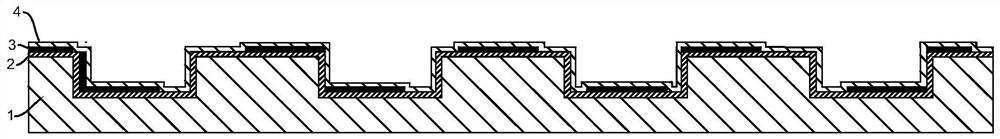

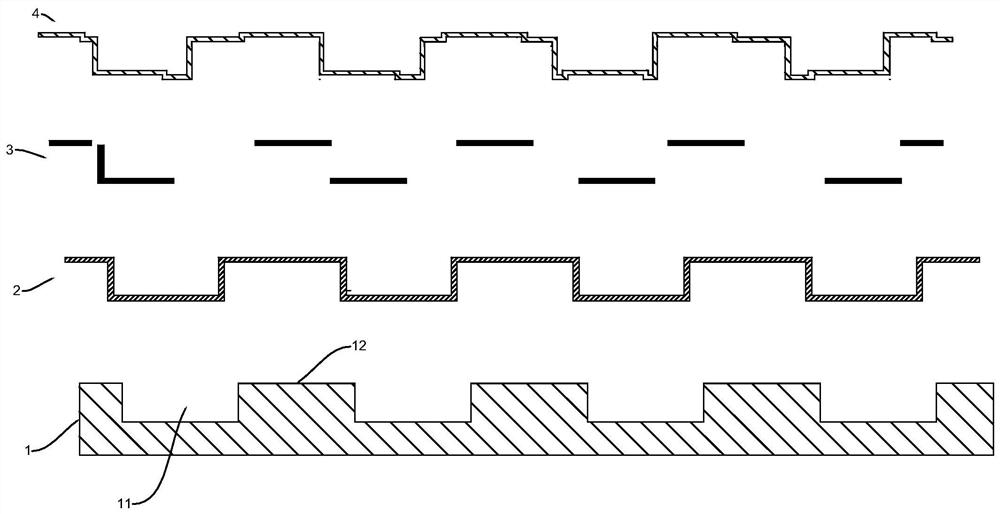

[0071] Example 1: If figure 1 , figure 2 Shown: an etched two-color decorative metal plate, the etched two-color decorative metal plate includes a metal plate 1, the surface of the metal plate 1 is etched with a concave pattern 11, and the non-concave part is opposite to a raised pattern 12; the concave pattern 11. The raised pattern 12 is colored with a black titanium coloring layer (black), and the black titanium coloring layer 2 is vacuum-plated with a PVD coating pattern layer (for example: titanium gold) PVD coating pattern layer (titanium gold) and a black titanium coloring layer ( The color of black) is different, and the part of the black titanium coloring layer 2 not covered by the PVD coating pattern layer forms a delamination pattern (hollow pattern) relatively, and the black titanium coloring layer can be seen through the delamination pattern (hollow pattern). The black titanium coloring layer within the hollow area of the pattern (hollowout pattern) also relat...

example 2

[0072] Example 2: If figure 1 , figure 2 Shown: an etched two-color decorative metal plate, the etched two-color decorative metal plate includes a metal plate 1, the surface of the metal plate 1 is etched with a concave pattern 1, and the non-concave part is opposite to a raised pattern 12; the concave pattern , The raised pattern is colored with a black titanium coloring layer (black), and the black titanium coloring layer is vacuum-plated with a PVD coating pattern layer (for example: sapphire blue), PVD coating pattern layer (sapphire blue) and black titanium coloring layer (black) The color of the black titanium coloring layer is not covered by the PVD coating pattern layer to form a delamination pattern (hollow pattern). The black titanium coloring layer can be seen through the delamination pattern (hollow pattern), and the delamination pattern (hollow pattern) can be seen. The black titanium coloring layer within the hollow area of the pattern) also relatively forms ...

specific Embodiment 1

[0074] A production process for etching two-color decorative metal plates is characterized in that it comprises the following steps:

[0075] 1) Lift the metal plate onto the screen printing platform, and print the pattern with ink through the screen printing screen; this pattern can be any design pattern style; the selected metal plate is a stainless steel metal plate;

[0076] 2) Dry the ink that has been screen-printed on the surface of the metal plate in an oven to cure the ink on the surface of the metal plate;

[0077] 3), transport the metal plate with solidified ink to the etching machine, etch the surface of the metal plate not covered by the ink with etching solution, so that the surface of the metal plate is etched with a concave pattern;

[0078] 4) Transport the metal plate with etched patterns to the ink removal equipment, soften and wash the previously printed ink with sodium hydroxide, so that the surface of the metal plate is formed with concave patterns due t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com