Temperature synchronous control method for hot runners of injection molding multi-mold-cavity mold

A mold hot runner and temperature control technology, which is applied in the field of synchronous control of hot runner temperature in injection molding multi-cavity molds, can solve the problems of hot runner temperature difference, poor injection molding effect, no synchronization, etc., and achieve uniform heating, improved effect, Improve the effect of thermal expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

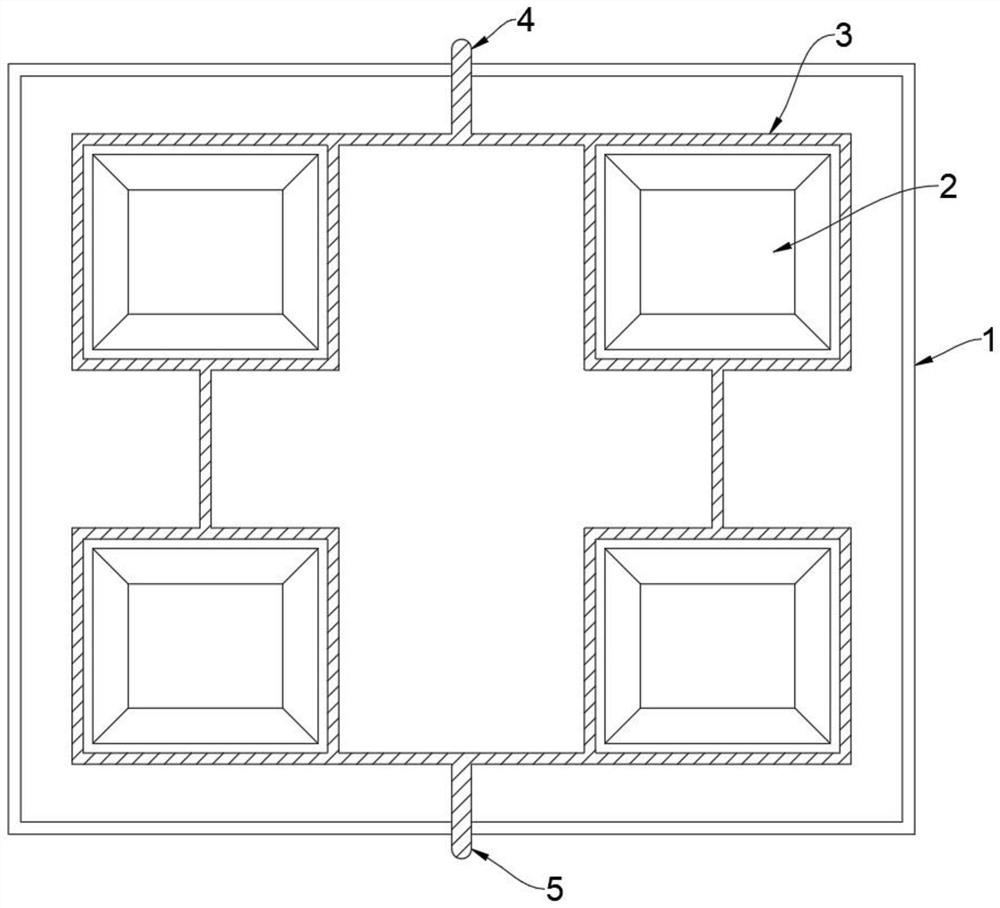

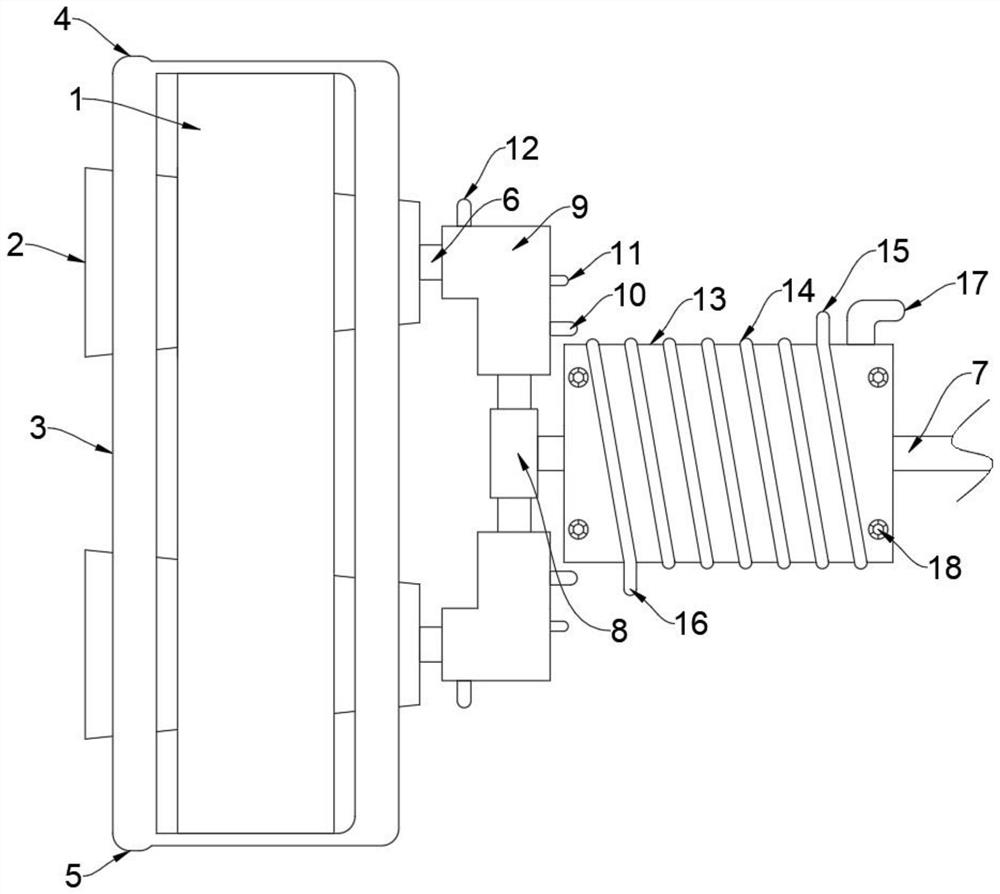

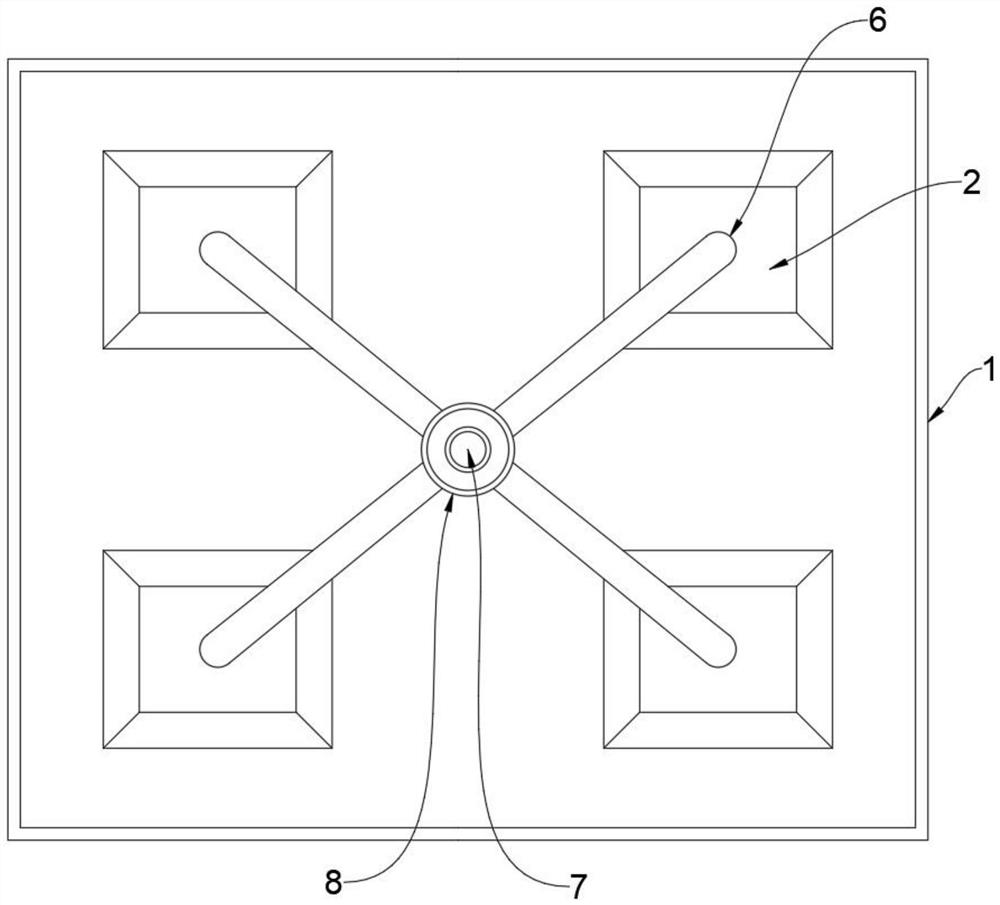

[0029] see Figure 1-5 , an embodiment provided by the present invention: an injection molding multi-cavity mold hot runner, including a mold 1, a mold cavity 2 is provided inside the mold 1, and the mold cavity 2 and the mold 1 are integrally structured, and the mold cavity 2 is provided with Four, the outside of the mold 1 is provided with a first cooling pipe 3, and the first cooling pipe 3 is fixedly connected with the mold 1, and one side of the mold cavity 2 is provided with a first hot runner 6, and the first hot runner 6 is connected to the mold cavity 2 Fixed connection, four first hot runners 6 are provided, one end of the first hot runner 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com