A Buck-Boost Controller Based on Current Mode

A current mode and controller technology, applied in control/regulation systems, instruments, electrical components, etc., can solve the problems of high dynamic loss of switching and difficult seamless switching, and achieve the effect of reducing dynamic loss and smooth and seamless switching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

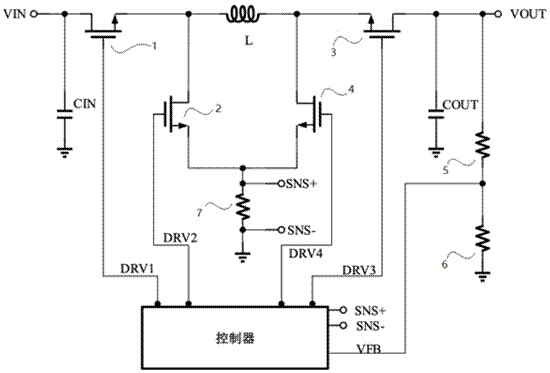

[0037] refer to figure 1 , figure 1 It shows a buck-boost converter composed of a controller, a voltage feedback circuit and a current sampling circuit. The buck-boost converter mainly includes two parts, namely the core controller and the voltage and current feedback loop that cooperates with the core controller , the controller outputs a DRV1 signal, a DRV2 signal, a DRV3 signal, and a DRV4 signal, and the voltage feedback loop includes a first switching tube 1, a second switching tube 2, a third switching tube 3 and a fourth switching tube 4, so The drain of the first switching tube 1 is connected to the VIN input signal, the gate of the first switching tube 1 is connected to the DRV1 signal of the controller, and the source of the first switching tube 1 is connected to the drain of the second switching tube 2; The drain of the third switching tube 3 is connected to the VOUT output signal, the grid of the third switching tube 3 is connected to the DRV3 signal of the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com