Rotation circulation device of motor iron core insulation paper assembling machine

A technology of iron core insulation and assembling machine, which is applied in laying solid insulation and other directions, can solve the problems of low paper loading efficiency and low iron core moving accuracy, and achieve the effects of improving work efficiency, improving position accuracy and preventing vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

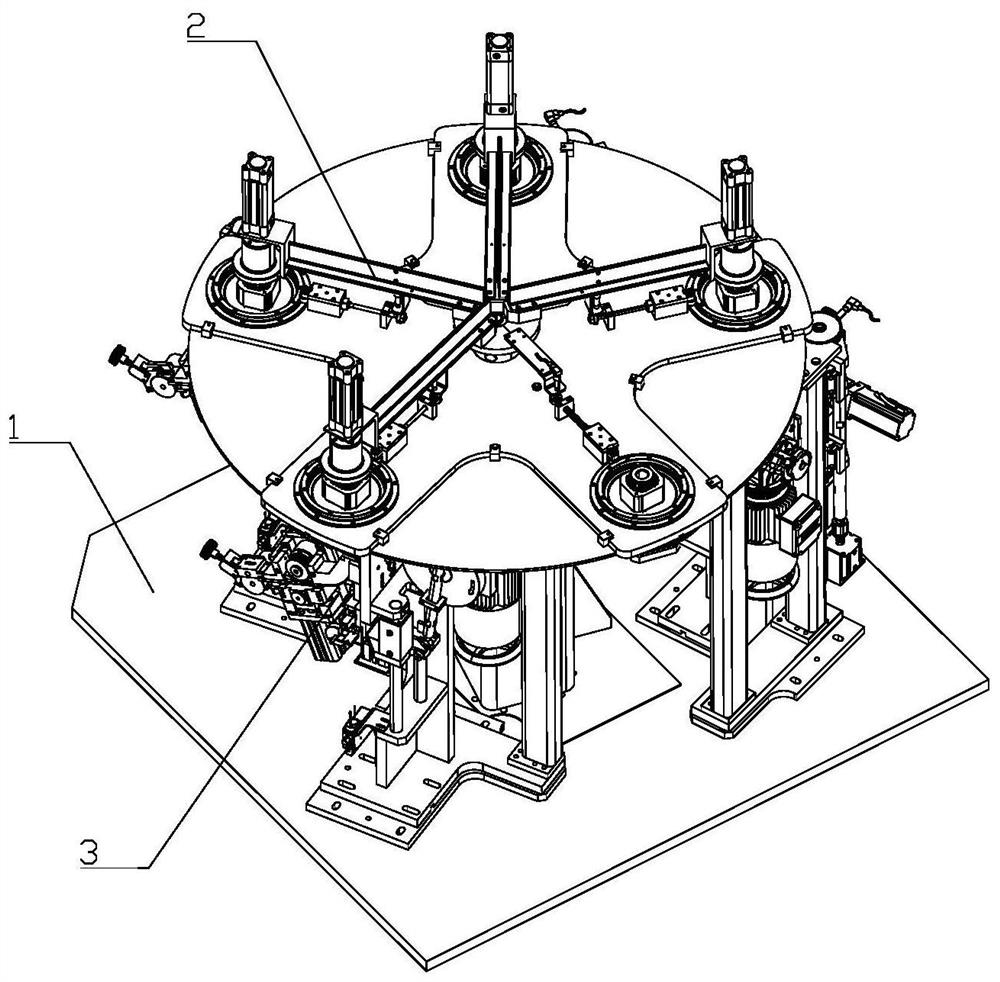

[0027] like figure 1 As shown, a motor core insulating paper assembly machine includes a frame 1, a rotating circulation device 2 and an insulating paper assembly device 3 installed on the substrate, and the rotating circulation device 2 is provided with a processing station and a loading and unloading station. The paper assembly device 3 is provided with multiple groups, and the insulating paper assembly device 3 corresponds to the processing station of the rotating circulation device 2; the rotating circulation device 2 is used to realize the turnover and rotation after the iron core is positioned, and the insulating paper assembly device 3 It is used to cut the insulating paper and assemble it into the slot of the iron core. The above-mentioned rotating and circulating device 2 is a rotating and circulating device of a motor iron core insulating paper assembly machine.

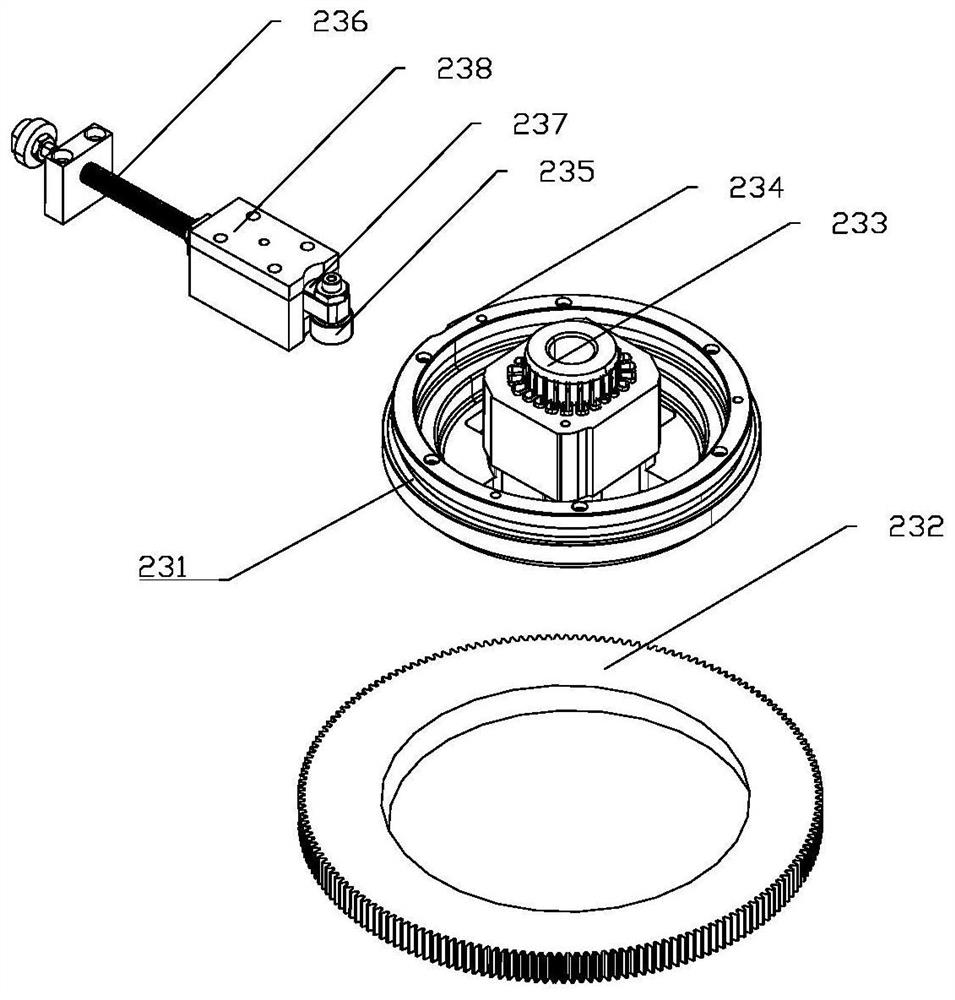

[0028] like figure 2 and image 3 As shown, the rotation flow device of a motor core insulation pape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com