Single-stress-element optical fiber chirped fiber bragg grating and preparation method thereof

A Bragg grating, chirped fiber technology, applied in cladding fiber, optical waveguide light guide, light guide and other directions, can solve the problems of fiber life and performance influence, deformation error fiber bending resistance process affecting the effect of chirped modulation, etc., to save cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

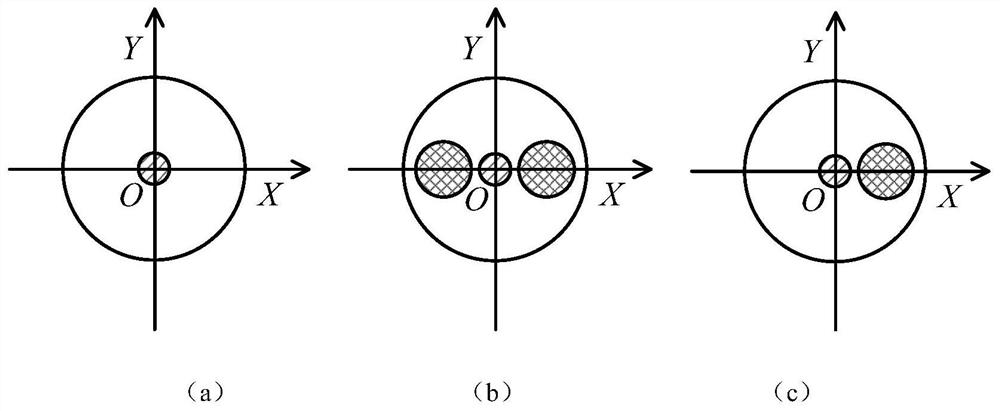

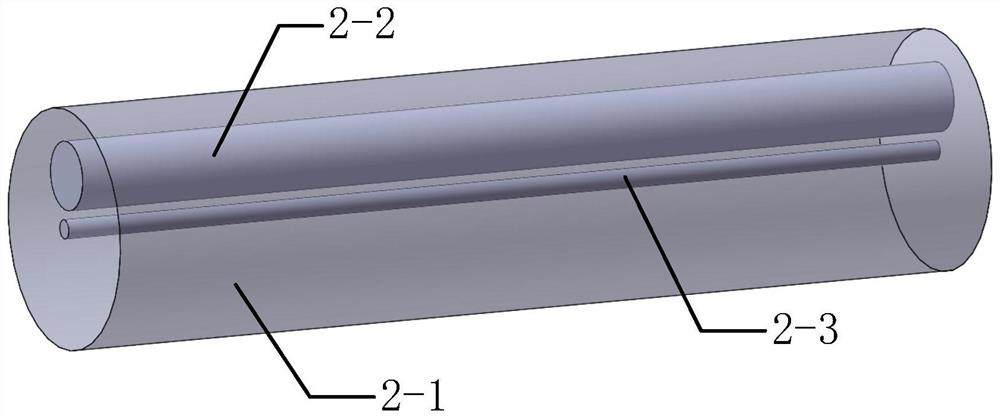

[0038] Example 1: A preparation method of a single-stress-element fiber-chirped fiber Bragg grating

[0039] Preferably, in this embodiment, the diameter of the stress element may be 32 microns, and its geometric center may be 26 microns from the geometric center of the optical fiber.

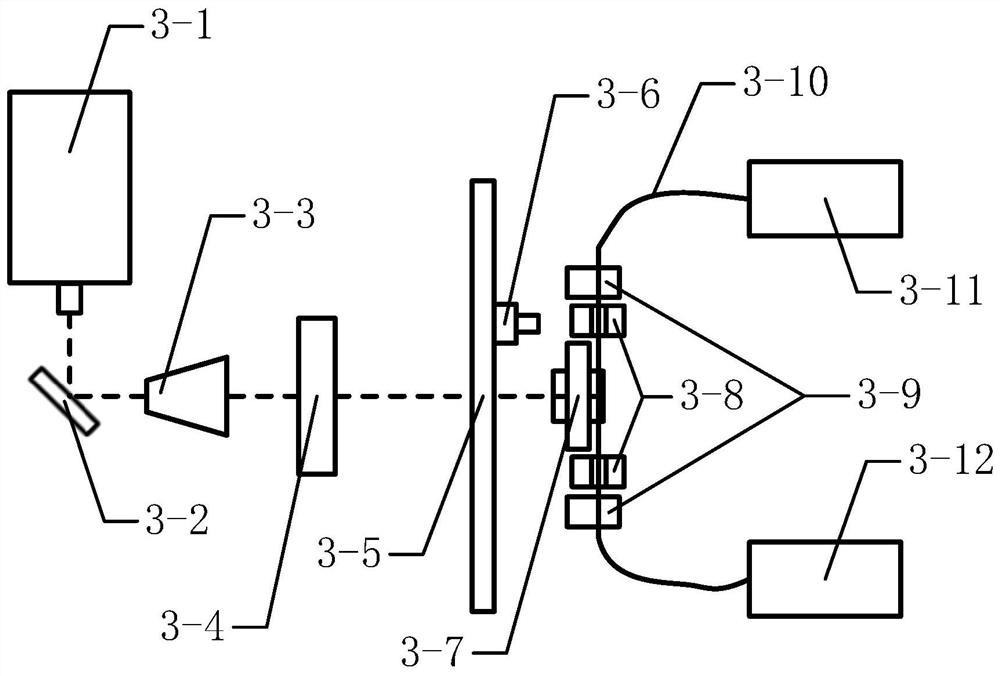

[0040] The chirped fiber Bragg grating writing system used in the present invention is as image 3 As shown, the preparation steps are as follows:

[0041] Step 1: Set the writing parameters of the excimer laser 3-1, and adjust the relative positions of the mirror part 3-2, the beam expander part 3-3 and the cylindrical lens part 3-4 in the writing system to collimate the ultraviolet laser beam, so that It can accurately focus on the core position of the single stress element optical fiber 3-10 to be written;

[0042] Step 2: Select a fiber Bragg grating phase mask with appropriate parameters, and place it on the mask holder to form fiber Bragg grating phase mask parts 3-7;

[0043] Step 3: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com