Pipe opening waterproof structure, water tank and water heater

A technology of waterproof structure and nozzle, applied in the direction of fluid heaters, lighting and heating equipment, pipe components, etc., can solve the problems of poor sealing effect, the sealant cover and the shell cannot be fully fitted, etc., to improve the sealing, The effect of enhancing tightness and enhancing waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment describes in detail the nozzle waterproof structure of the present invention.

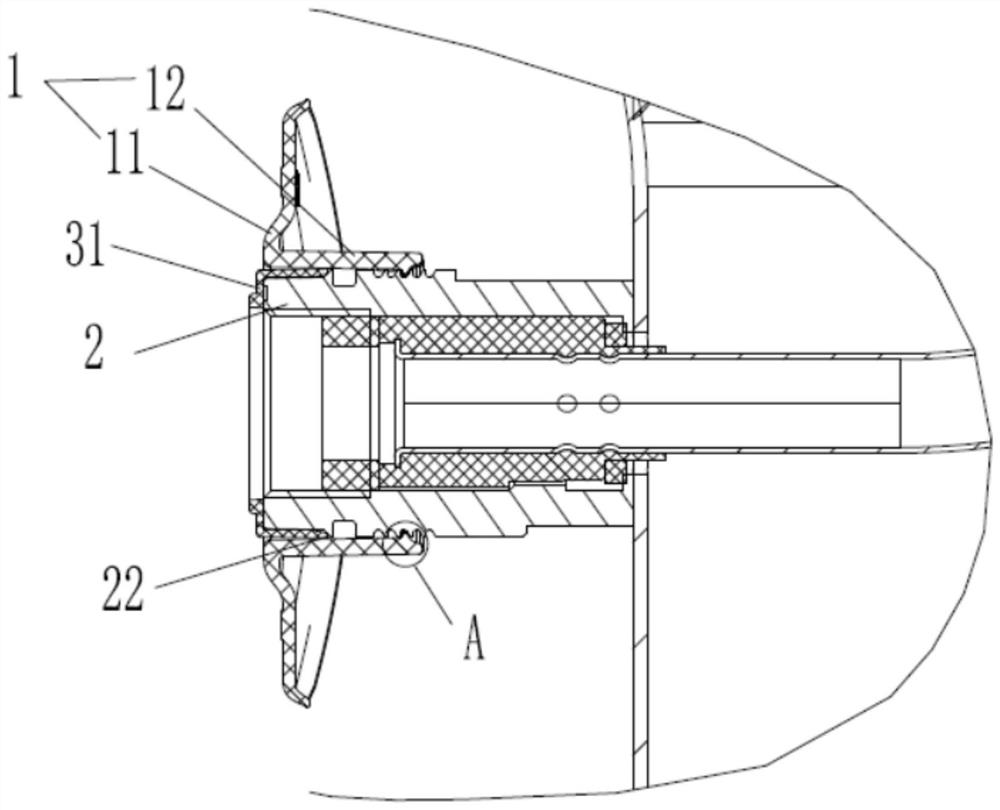

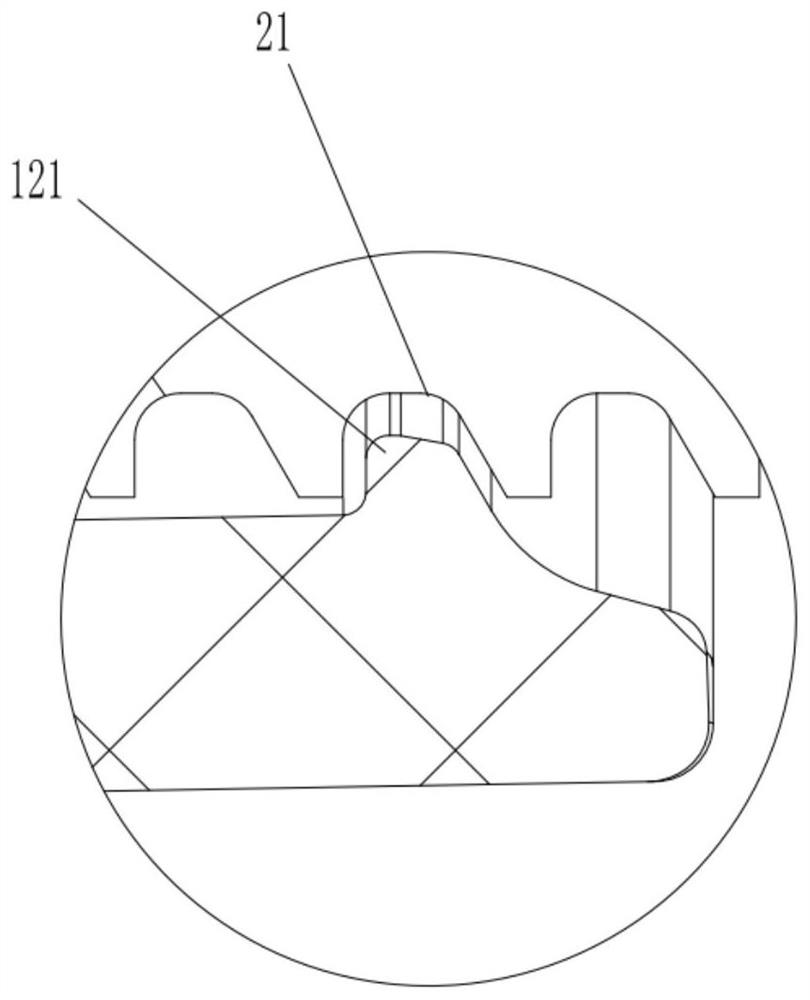

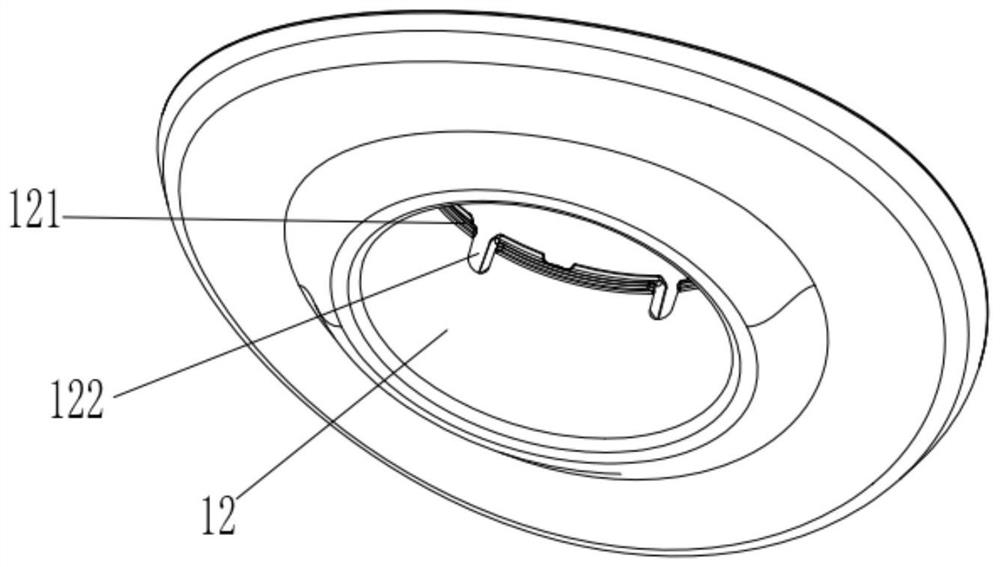

[0035] The nozzle waterproof structure of the present embodiment includes a sealant cover 1 and a pipe joint 2, such as figure 1 shown. Preferably, the sealant cover 1 includes a mounting portion 11 and a through pipe 12 connected to the mounting portion 11, such as figure 1 shown. More preferably, the installation part 11 is installed on the surface of the object to be sealed and matches the structure of the surface of the object to be sealed, and the through pipe 12 is installed in the nozzle of the object to be sealed. More preferably, the pipe joint 2 is assembled in the through pipe 12 and fixedly connected with the through pipe 12, and the mounting part 11 is closely attached to the surface of the part to be sealed, such as figure 1 shown. The installation part 11 of this embodiment matches the surface structure of the part to be sealed, and it can also be said that...

Embodiment 2

[0050] This embodiment describes the water tank of the present invention in detail.

[0051] The water tank of this embodiment includes a shell and a spout disposed on the shell, and the spout is provided with the spout waterproof structure of any one of the technical solutions in Embodiment 1. Preferably, the nozzle here can be a water inlet nozzle or a water outlet nozzle. In the water tank of this embodiment, the nozzle is provided with the nozzle waterproof structure of any one of the technical solutions in Embodiment 1, so that the nozzle is well sealed and the water tank has excellent waterproof performance.

Embodiment 3

[0053] This embodiment describes the water heater of the present invention in detail.

[0054] The water heater of this embodiment is characterized by comprising the water tank of any one of the technical solutions in Embodiment 2. The water heater in this embodiment includes the water tank according to any one of the technical solutions in Embodiment 2, so that the product quality of the water heater is improved, and the quality risk of corrosion of the heat exchanger caused by external rainwater can be avoided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com