Ultra-low emission integrated system of supercritical carbon dioxide coal-fired boiler

A carbon dioxide, coal-fired boiler technology, applied in indirect carbon dioxide emission reduction, incinerators, combustion methods, etc., can solve the problems of high temperature air preheater blockage and wear, reduce pipeline blockage, reduce maintenance work, and extend service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

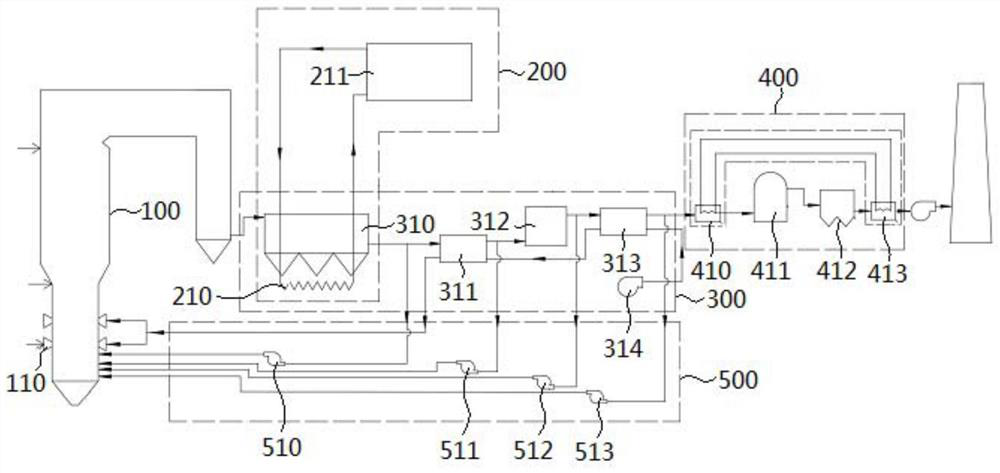

[0038] Such as figure 1 and figure 2 As shown, the arrows in the figure indicate the direction of travel of hot gas and materials. The supercritical carbon dioxide coal-fired boiler ultra-low emission integrated system of this embodiment includes a boiler unit 100 , a waste heat recovery unit 200 , a dust removal and denitrification unit 300 , a desulfurization unit 400 and an air circulation unit 500 .

[0039] In this embodiment, the boiler unit 100 includes an ammonia injection burner 110, and the ammonia injection burner 110 may be the burner in the application number 202010289079.X.

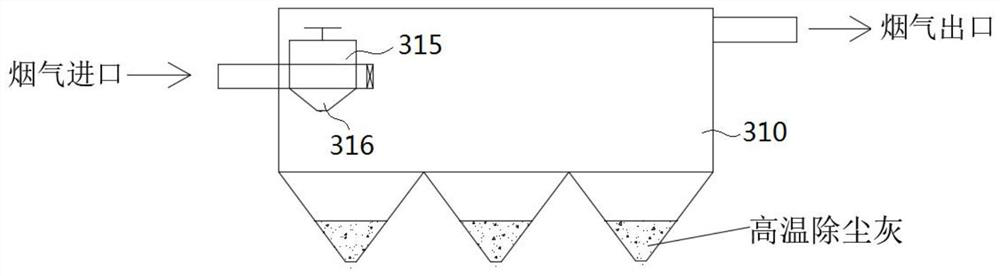

[0040] In this embodiment, the dust removal and denitration unit 300 includes a high temperature dust collector 310 , a high temperature air preheater 311 , an SCR denitration reactor 312 , a low temperature air preheater 313 and a blower 314 connected in sequence.

[0041] In this embodiment, the waste heat recovery unit 200 includes a heat exchange tube 210 and a bottom circulation syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com