High-strength straight gear and manufacturing method thereof

A manufacturing method and technology of spur gears, applied in the direction of belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of inconvenient overall disassembly and assembly of gears, increase replacement and maintenance costs, etc., and achieve improved alignment connection Effect, convenient manufacture, and effect of improving installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

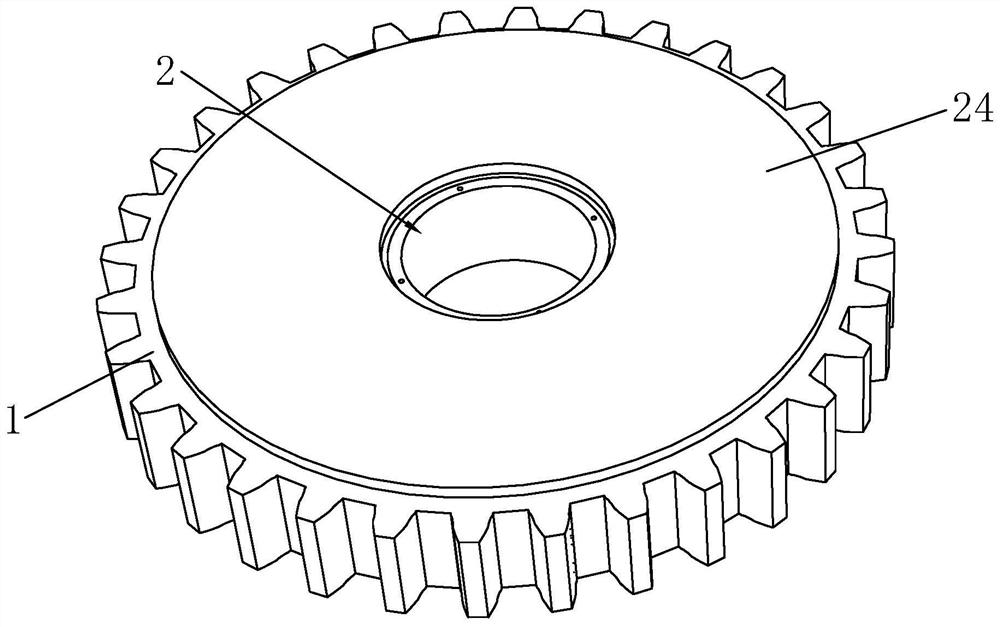

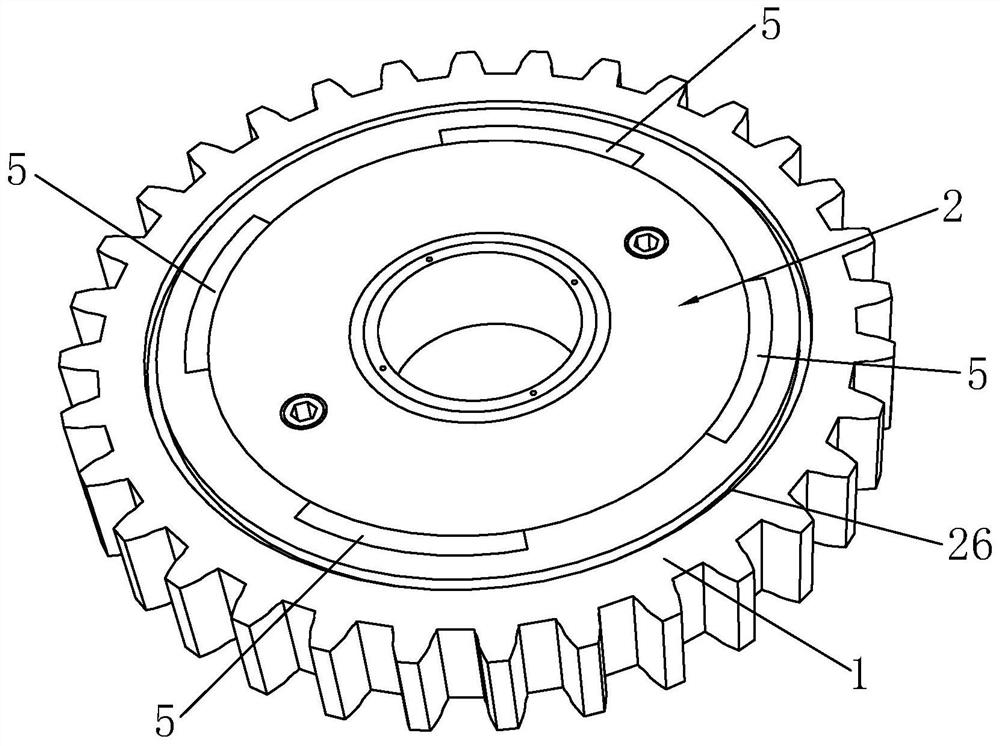

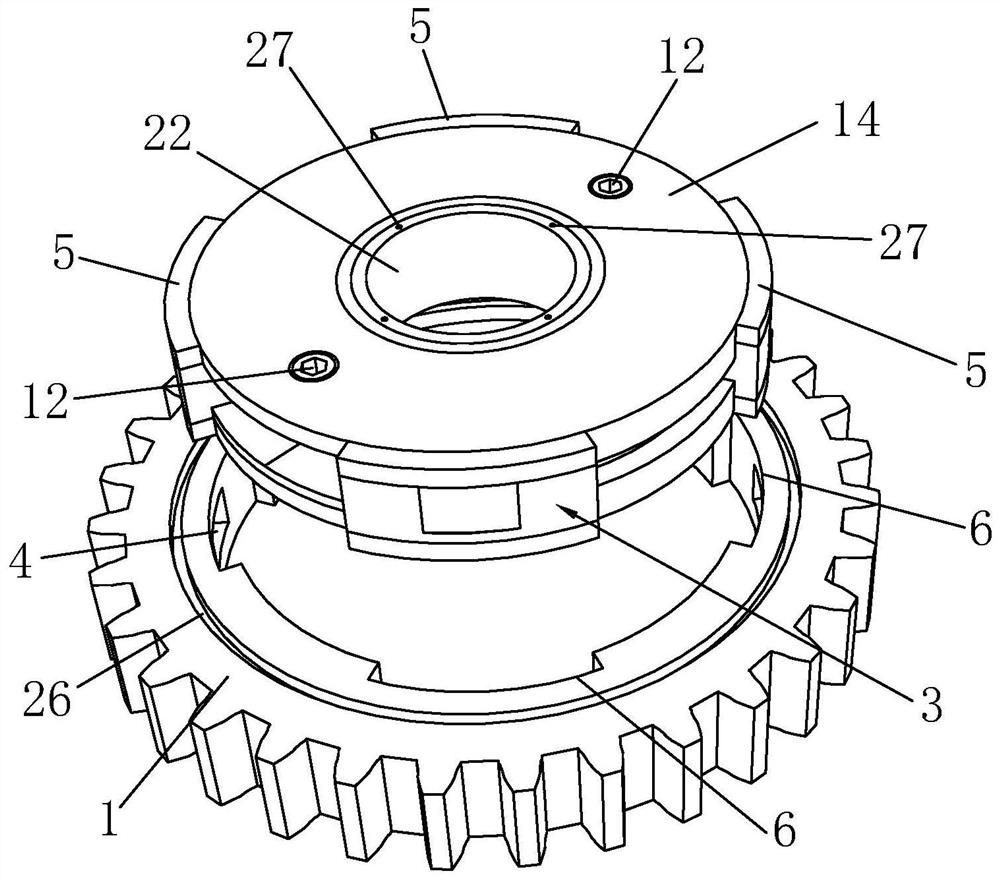

[0039] Such as Figure 1 to Figure 7 As shown, it is a high-strength spur gear of the present invention, including a ring gear 1 and a gear hub 2, the gear hub 2 is arranged in the ring gear 1, the gear hub 2 is provided with a fixing mechanism 3, and the ring gear 1 is provided with a fixing groove 4, The fixing mechanism 3 is stuck in the fixing groove 4 , the gear hub 2 is provided with a positioning protrusion 5 , the ring gear 1 is provided with a positioning groove 6 , and the positioning protrusion 5 is arranged in the positioning groove 6 . Adopting the split structure of the ring gear 1 and the gear hub 2, on the one hand, fewer parts can be replaced when the ring gear 1 is damaged, which saves the cost of replacement and maintenance. Reinstallation after disassembly affects the installation accuracy of the gear, resulting in long time and low efficiency for the replacement of the gear. However, through the split design, the ring gear 1 can be directly replaced withou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com