A control structure of a top drive device

A technology of control structure and top drive device, which is applied to the drilling drive device, transmission device parts, wellbore/well components, etc. in the wellbore, which can solve the problem that the remote control internal blowout preventer shut-off mechanism occupies a large space, and the lifting ring tilts the oil cylinder. The problems of large span and complex hydraulic control pipeline can improve the load condition, the stress condition and the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

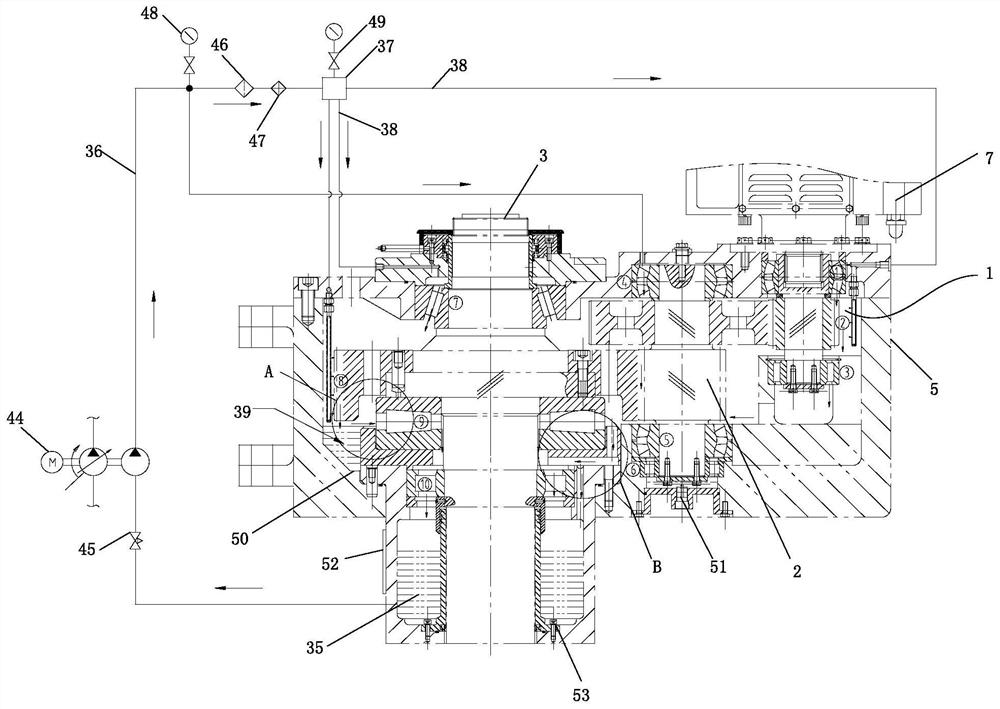

[0038] As shown in the figure, the control structure of a top drive device disclosed by the present invention includes a main motor input transmission mechanism 1, an intermediate shaft transmission assembly 2 connected with the main motor input transmission mechanism 1, and is driven by the intermediate shaft transmission assembly 2. The kelly 3 is used for the shut-off mechanism of the remote control internal blowout preventer in the kelly 3, and the lubrication system for controlling the lubrication of each bearing lubrication point in the structure;

[0039] The main motor input transmission mechanism 1 includes a gear box cover 4 and a gear box body 5, a main motor 7 installed on the gear box cover 4 through a motor connection flange 6, and an input shaft connected to the main shaft of the main motor 7 by a spline 8. The self-aligning roller bearing 9 arranged on the periphery of the connection between the main shaft and the input shaft 8 is used to ensure the centering ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com