An upflow residual oil hydrogenation reaction system and residual oil hydrogenation treatment method

A reaction system and hydrotreating technology, applied in the treatment of hydrocarbon oil, petroleum industry, refining to remove heteroatoms, etc., can solve the problems of difficult temperature control, unstable temperature, high hydrogenation activity, and achieve stable temperature and reduced Severe fluctuations, the effect of increasing the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

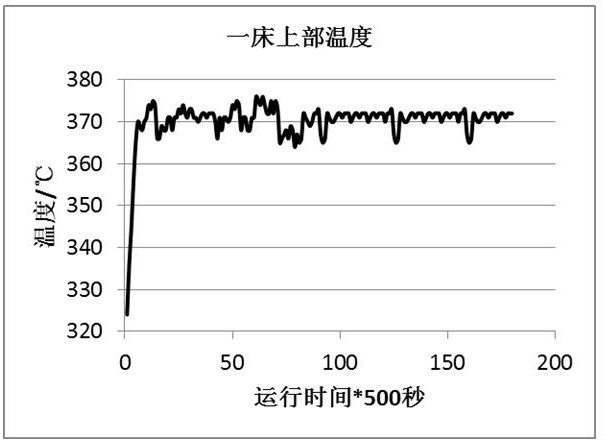

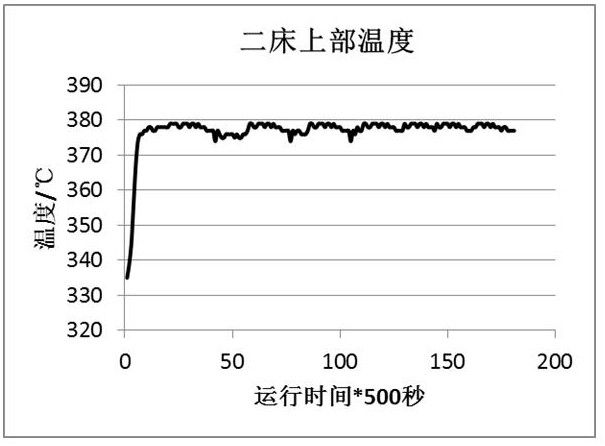

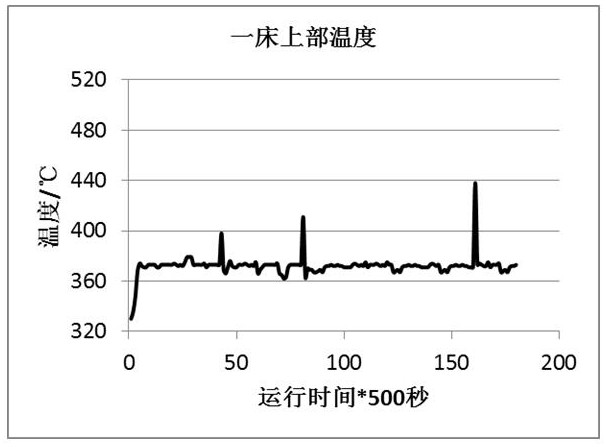

[0045] In the present embodiment, the hydrogenation reaction of the residue is hydrotreated with a top flow hydrogenation reactor. The upper flow reactor sets two catalyst beds having a volume ratio of 1: 1, and each catalyst bed is filled with a 420 ml catalyst, and the total amount of mounting catalyst is 840 mL. The first catalyst bed is made of a hydrotreating catalyst FZC-11ua, and the second catalyst bed is employed by hydrogenating treatment catalyst FZC-10U, wherein the catalyst properties are shown in Table 1.

[0046] The feed used is a typical Middle Eastern residue, and hydrogenous reaction is carried out in a hydrogenation reactor in the upper flow residue, which is mainly removed from impurities such as metal to obtain an upper flow hydrogen production oil. The main process conditions are shown in Table 2. The nature of the hydrogen generated by the upper flow reactor is shown in Table 3.

[0047] A material dispenser and a cold hydrogen tube are provided between eac...

Embodiment 2

[0053] In the present embodiment, the hydrogenation reaction of the residue is hydrotreated with a top flow hydrogenation reactor. The upper flow reactor is provided with three catalyst beds that fill 250 ml catalyst along the first catalyst bed along the stream direction. The second catalyst bed is filled with 300 ml catalyst, and the third catalyst bed is filled with 350 ml catalyst filling catalyst. The total amount is 900ml. The first bed of the upper flow reactor employs a hydrogenation treatment catalyst FZC-11UB, and the second bed is used to hydrotion treatment catalyst FZC-11ua, the third bed is used to hydrotion treatment catalyst FZC-10U.

[0054] The feed used is a typical Middle Eastern residue, and hydrogenous reaction is carried out in a hydrogenation reactor in the upper flow residue, which is mainly removed from impurities such as metal to obtain an upper flow hydrogen production oil. The main process conditions are shown in Table 4. The nature of the hydrogen gen...

Embodiment 1 and comparative example 1

[0062] Table 2 Example 1 and Comparative Example 1 Main Process Conditions

[0063] project Example 1 Comparative Example 1 Upgrade catalyst number First bed: FZC11U / second bed layer: FZC10U First bed: FZC10U / second bed layer: FZC11ua Reaction pressure, MPA 17.0 17.0 Volume vacancy, h -1

0.38 0.38 Hydrogen oil volume ratio 300 300 First bed temperature, ° C 370 373 Second bed temperature, ° C 378 380

[0064] Table 3 Embodiment 1 and Comparative Example 1 The main properties of the hydrogenated oil used

[0065] project Feeding 1 Example 1 Comparative Example 1 S, wt% 4.17 2.36 2.40 N, μg / g 3332 2353 2421 CCR, WT% 11.63 8.77 8.91 Density (20 ° C), Kg / M 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com