Preparation method of ZrB2 powder with uniform and controllable 10B abundance

A powder and uniform technology, applied in the field of ZrB2 powder preparation, can solve the problems of poor abundance stability, uneven distribution of B abundance, and inability to meet the requirements, so as to reduce the content of impurity elements and achieve stable and controllable high uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

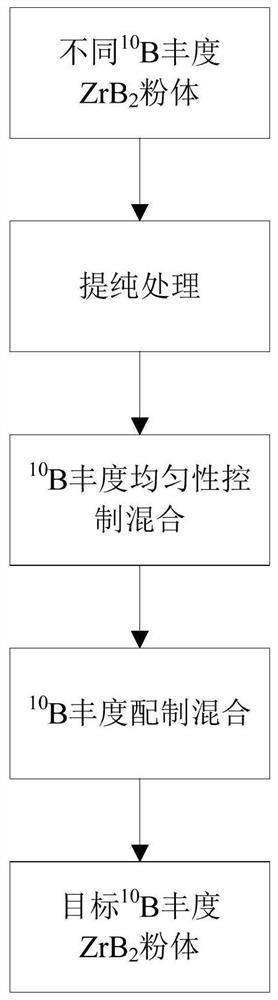

Method used

Image

Examples

Embodiment 1

[0025] Example 1: 10 ZrB with B abundance 10wt.% 2 Powder preparation

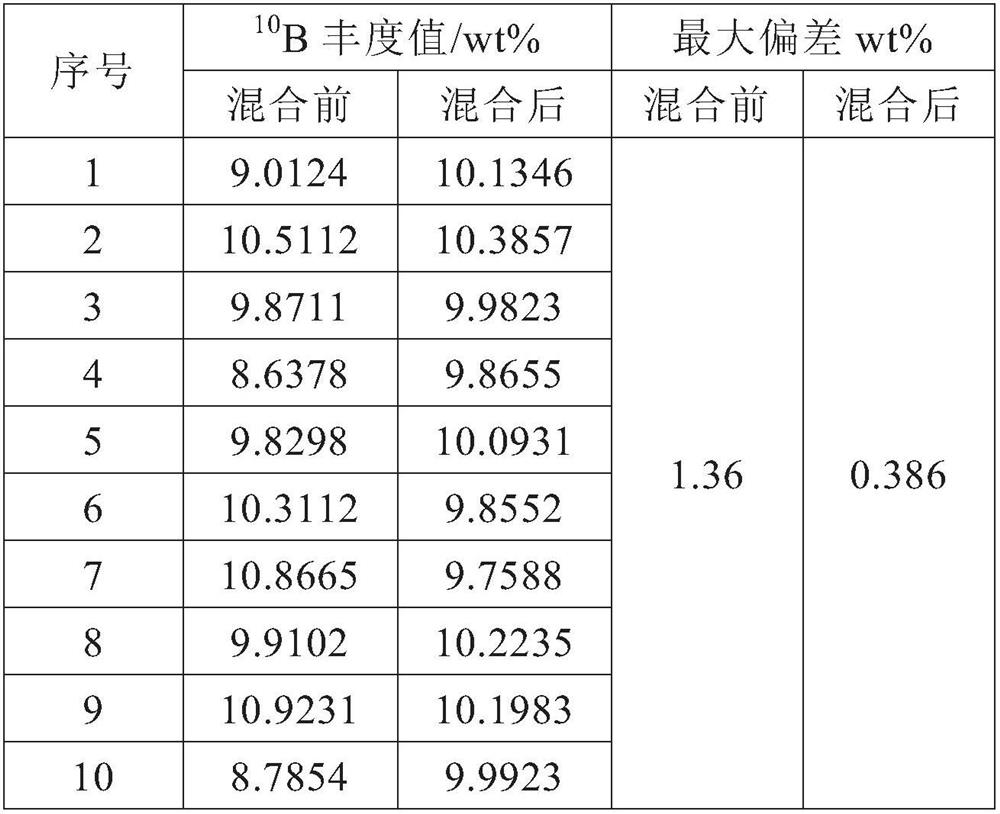

[0026] Prepared by carbothermal reduction 10 B abundance ZrB 2 Powder 20kg, ZrB 2 Powder Theory 10 The abundance value of B is 10wt.%, the powder is sampled at 10 points 10 B abundance, the results are shown in Table 3, 10 The maximum deviation of B abundance is 1.36wt.%; use a mixed solution of 1mol / L hydrochloric acid plus 1mol / L nitric acid to treat the above-mentioned ZrB 2 The powder is pickled, wherein the ratio of hydrochloric acid to nitric acid is 3:1 by volume; the powder after pickling is mixed with a high-speed mixer, the mixer speed is 1500r / min, and the mixing time is 10min. 10 ZrB with uniform abundance 2 Powder, powder purity > 99.9% (as shown in Table 2), 10 B abundance deviation <0.4wt.% (as shown in Table 3).

[0027] Table 2 Example 1 related ZrB 2 Analysis results of powder purity

[0028] Impurity elements Content / ppm Impurity elements Content / ppm Impurit...

Embodiment 2

[0031] Example 2: 10 ZrB with B abundance of 30wt.% 2 Powder preparation

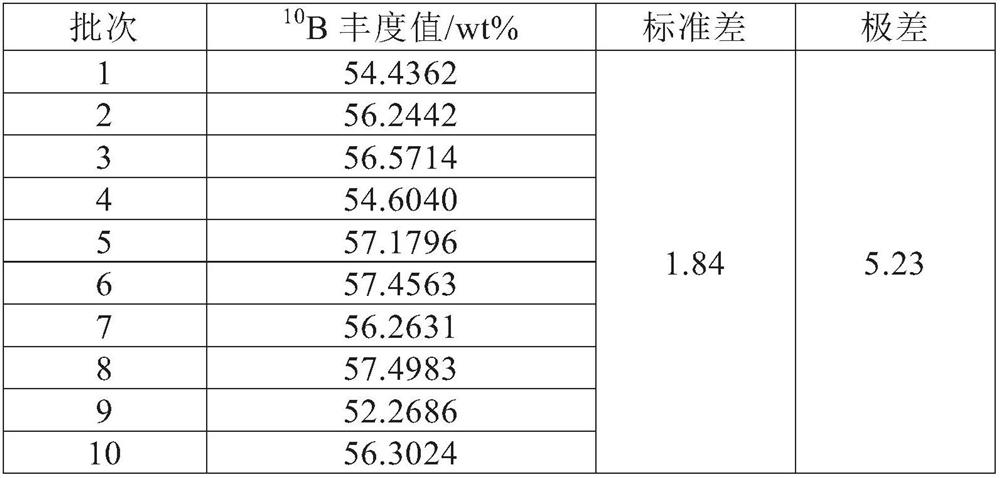

[0032] Prepared by sol-gel method 10 ZrB with B abundance of 18.5wt.% 2 Powder 5kg, prepared by carbothermal reduction method 10 ZrB with a B abundance of 55wt.% 2 The powder is 20kg, and the powder is sampled and tested at 10 points respectively. 10 B abundance, the results are shown in table 5; Utilize the mixed solution of 3mol / L hydrochloric acid to add 1mol / L nitric acid to the above two kinds of ZrB 2 The powder is pickled, wherein the ratio of hydrochloric acid to nitric acid is 1:1 by volume; the powder after pickling is mixed by a three-dimensional motion mixer, the spindle speed of the mixer is 25r / min, and the time is 30min to obtain two kinds of 10 ZrB with highly uniform B abundance distribution 2 powder, powdery 10 B abundance deviation values are all10 ZrB with a B abundance of 55wt.% 2 Powder 6.3kg, 10ZrB with B abundance of 18.5wt.% 2 13.7kg of powder was mixed by a high-sp...

Embodiment 3

[0037] Example 3: 10 ZrB with B abundance 50wt.% 2 Powder preparation

[0038] prepared by carbothermal reduction 10 ZrB with B abundance of 95wt.%, 20wt.% and 60wt.% 2 Each powder is 20kg; the prepared powder is pickled with a mixed solution of 3mol / L hydrochloric acid and 1mol / L hydrogen peroxide, wherein the ratio of hydrochloric acid to hydrogen peroxide is 5:1 by volume; The motion mixer is mixed, the spindle speed of the mixer is 20r / min, and the time is 60min, and 3 kinds of 10 ZrB with highly uniform B abundance distribution 2 powder, powdery 10 B abundance deviations are all 10 ZrB with B abundance of 95wt.% 2 Powder 5.714kg, 10 ZrB with B abundance of 20wt.% 2 Powder 10kg, 10 ZrB with a B abundance of 60wt.% 2 Powder 4.286kg, adopt high-speed mixer to mix, mixer speed 1300r / min, mixing time 60min, get 10 ZrB with B abundance 50wt.% 2 Powder 20kg, powder purity > 99.9%, 10 B abundance deviation <0.3wt.%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com