Efficient chemical raw material grinding and separating device

A technology for chemical raw materials and separation devices, which is applied in solid separation, chemical instruments and methods, and filtration and screening. It can solve the problems of inability to sieve raw material particles, poor grinding effect, and unfavorable improvement of work efficiency, etc., and achieve fast and convenient working process. , quicker sieving, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

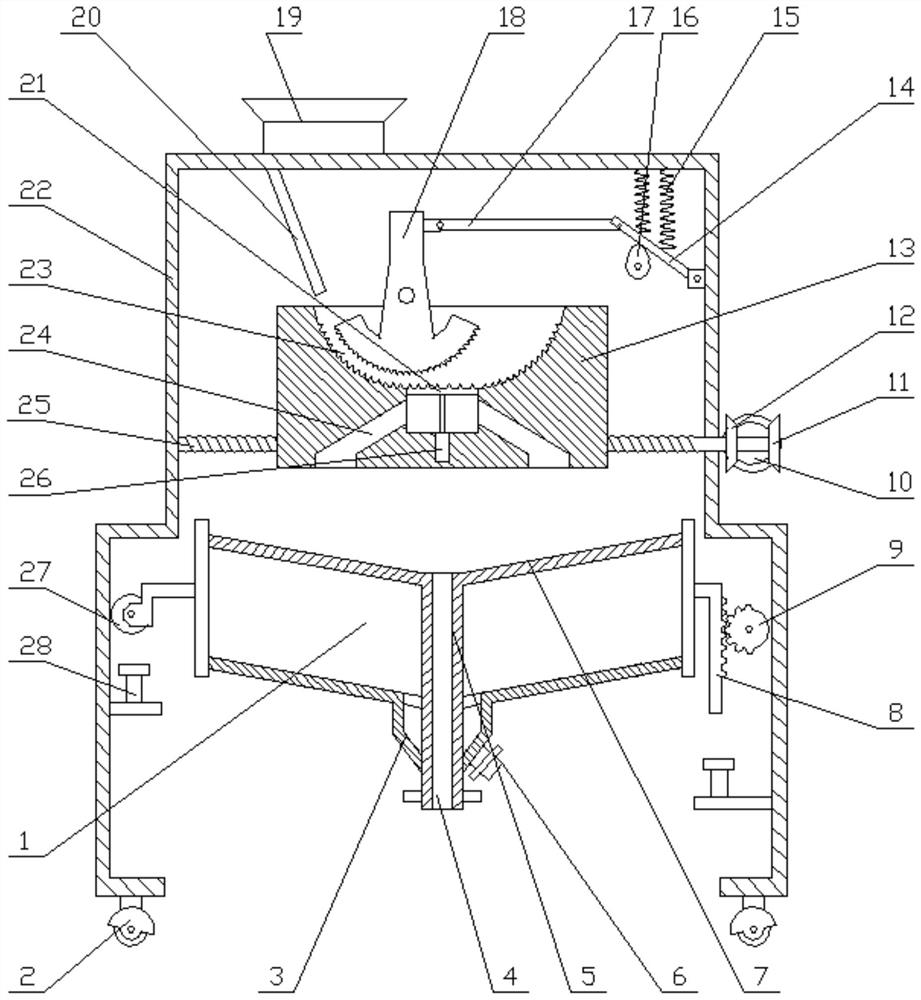

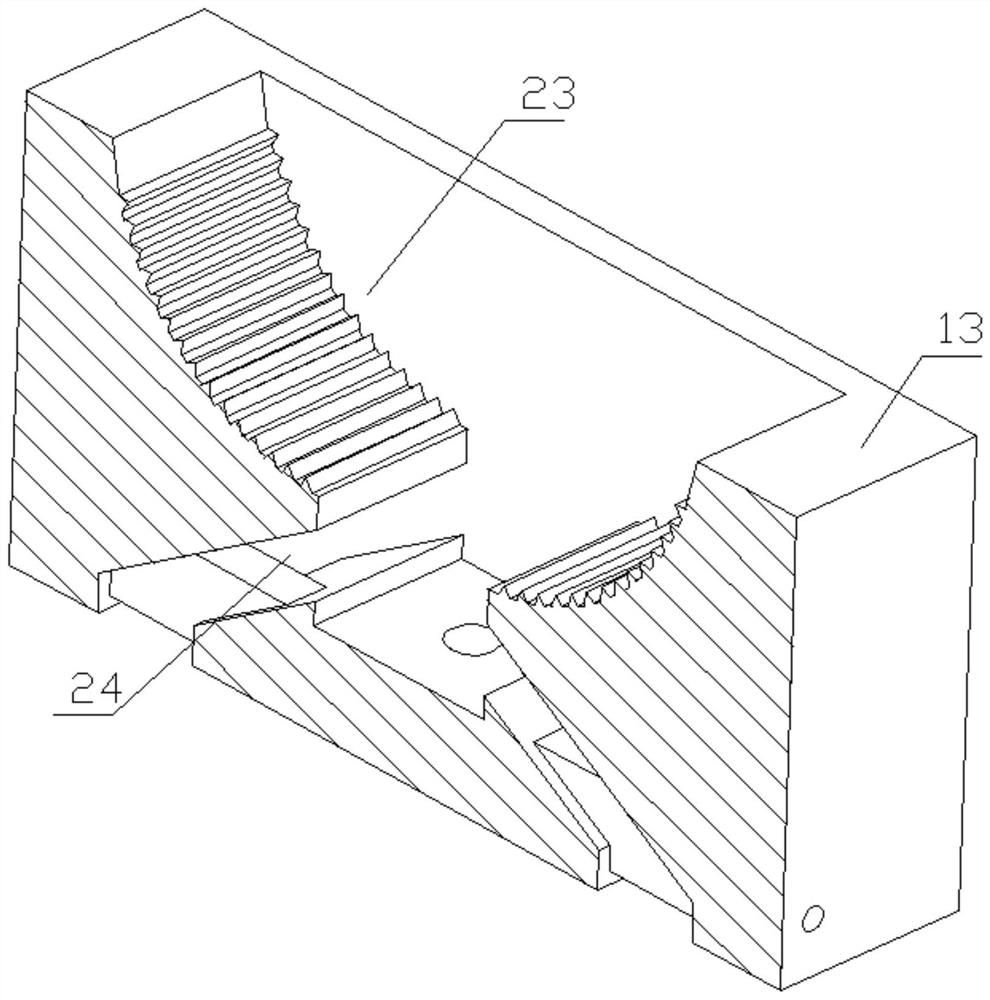

[0024] see figure 1 , a high-efficiency grinding and separating device for chemical raw materials, including a housing 22, the upper end of the housing 22 is provided with a feed port 19 for easy feeding, and the lower side of the feed port 19 is provided with a sliding plate 20, which is fixedly connected The inner wall of the housing 22 is provided with a sliding plate 20 to facilitate the sliding of raw materials into the abrasive hopper 13. The lower side of the housing 22 is provided with a sub-sieving mechanism 1, and the sub-sieving mechanism 1 includes an upper material distribution layer 7, and the upper material distribution layer The middle part of 7 is provided with a feed channel 5, and the lower end of the feed channel 5 is provided with a first discharge port 4, and the larger particles are discharged from the first discharge port 4, and the lower side of the upper material distribution layer 7 is provided with a lower material receiving layer 3, and the lower ma...

Embodiment 2

[0027] see figure 1 The difference between this implementation and the above-mentioned embodiment 1 is that the left and right sides of the lower end of the housing 22 are fixedly connected to the moving wheels 2, and the moving wheels 2 are universal wheels with brakes, and the moving wheels 2 are set to facilitate the movement and fixing of the device.

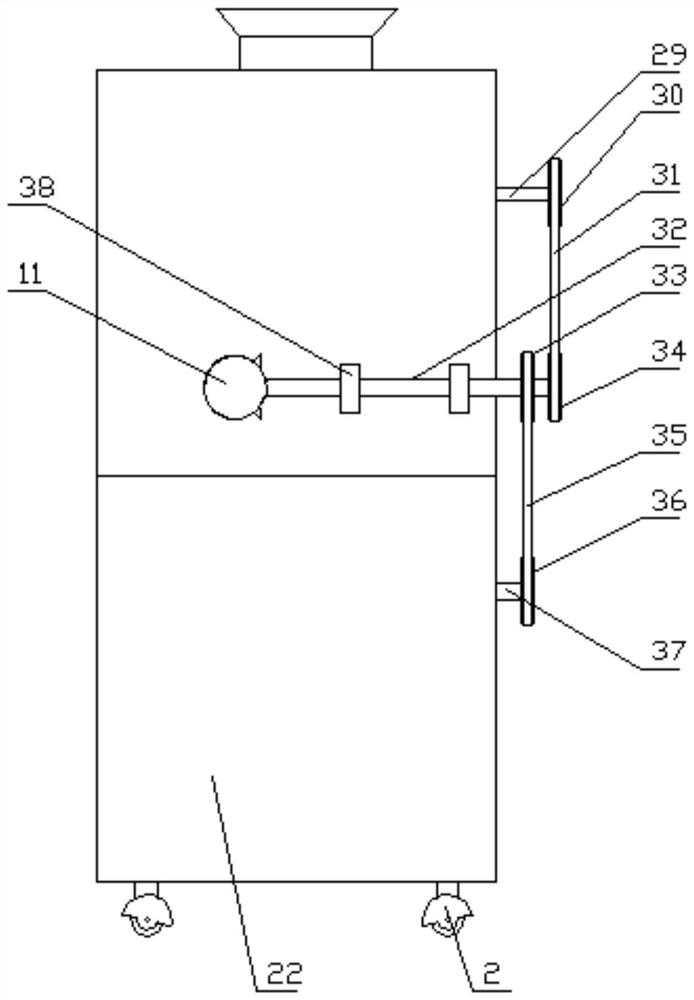

[0028] The working principle of the present invention is: when using the high-efficiency chemical raw material grinding and separation device for chemical raw material grinding, the raw material is first input through the feed port 19, and the raw material will be slid to the abrasive through the sliding plate 20 In the bucket 13, open the driving mechanism, the driving mechanism drives the first rotating rod 29, the second rotating rod 32 and the third rotating rod 37 to rotate through the transmission mechanism, and the rotation of the first rotating rod 29 will make the cam 16 rotate and control the pulling of the warping ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com