Sand screening device for construction

A screening device, sand technology, applied in the direction of filter screen, solid separation, grid, etc., can solve problems such as clumping together, poor screening efficiency, uneven sand distribution, etc., to improve sand screening efficiency and speed up screening speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

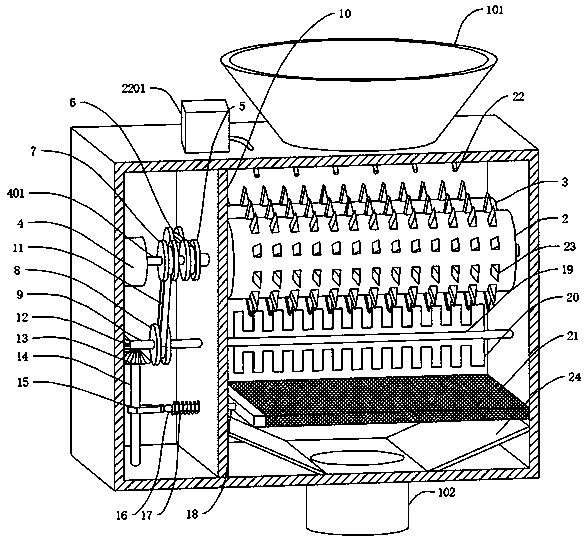

[0034] refer to Figure 1-3 , a sand screening device for construction, comprising a screening box 1 and a vibrating screen plate 21, the top of the screening box 1 is connected with a feed port 101, the bottom of the screening box 1 is connected with a discharge port 102, and the inner side wall of the screening box 1 is connected with a partition 10. The partition 10 divides the screening box 1 into a drive chamber and a screening chamber. The inner wall of the screening chamber is connected to the first rotating shaft 201 and the second rotating shaft 301 in rotation, and the outer walls of the first rotating shaft 201 and the second rotating shaft 301 are respectively connected to the first rotating shaft. The pressing roller 2 and the second pressing roller 3, and the end of the first rotating shaft 201 and the second rotating shaft 301 away from the inner wall of the screening chamber extends through the partition 10 to the inside of the driving chamber, and the first pre...

Embodiment 2

[0037] refer to Figure 2-3 , a sand screening device for construction, which is basically the same as Embodiment 1, the difference is that the first linkage assembly includes a first driving pulley 5 and a first driven pulley 6, and the first driving pulley 5 is connected to the On the outer wall of the three rotating shafts 401, the first driven pulley 6 is connected to one end of the second rotating shaft 301 placed inside the driving cavity, and the first driving pulley 5 is connected to the first driven pulley 6 through the belt 11;

[0038] The rotation of the third rotating shaft 401 drives the first driving pulley 5 to rotate, and the first driving pulley 5 drives the first driven pulley 6 to rotate through the belt 11, so that the first driving pulley 5 and the first driven pulley 6 are respectively Drive the first rotating shaft 201 and the second rotating shaft 301 to rotate together.

Embodiment 3

[0040] refer to Figure 2-3 , a sand screening device for construction, which is basically the same as Embodiment 2, the difference is that the second linkage assembly includes a second driving pulley 7 and a second driven pulley 8, and the second driving pulley 7 and the third The outer wall of the rotating shaft 401 is connected, the second driven pulley 8 is connected with the outer wall of the fourth rotating shaft 9 placed inside the driving cavity, and the second driving pulley 7 is connected with the second driven pulley 8 through the belt 11;

[0041] Dispersing assembly comprises stirring rod 19 and stirring blade 20, and stirring rod 19 is connected with an end that places the fourth rotating shaft 9 inside the screening cavity, and stirring blade 20 is connected on the rod wall of stirring rod 19;

[0042] The stirring blade 20 is a toothed structure, and the distance between the stirring rod 19 and the vibrating sieve plate 21 is half of the width of the stirring b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com