A gas-water separation component, fuel cell hydrogen circulation system and application

A fuel cell and circulation system technology, applied in the direction of fuel cells, power system fuel cells, separation methods, etc., can solve the problems of large resistance loss of gas-water separators, inoperable ejectors, and increased system components, and achieve widening work. Range, volume and weight reduction, effect of strong water separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

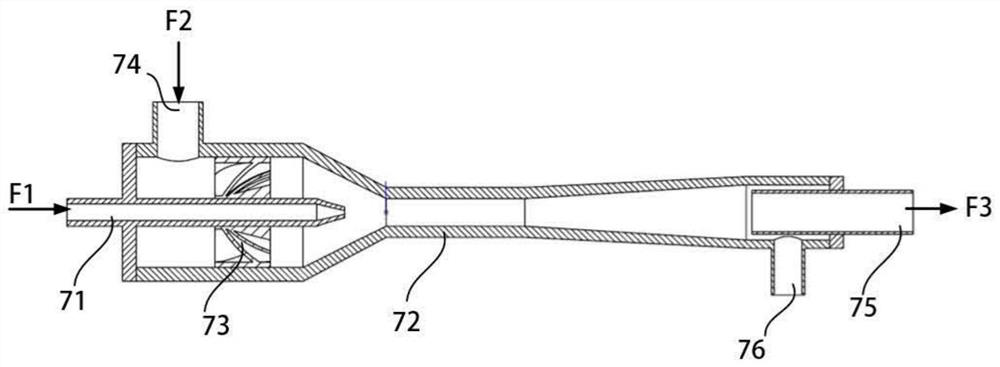

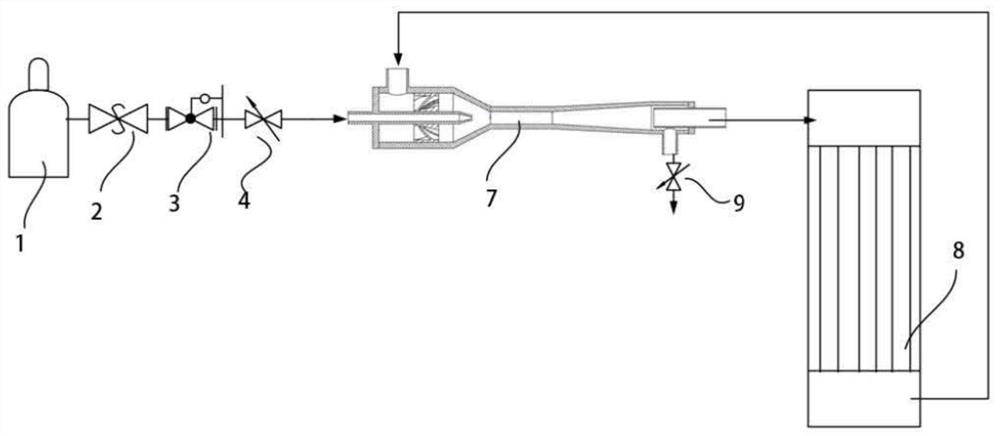

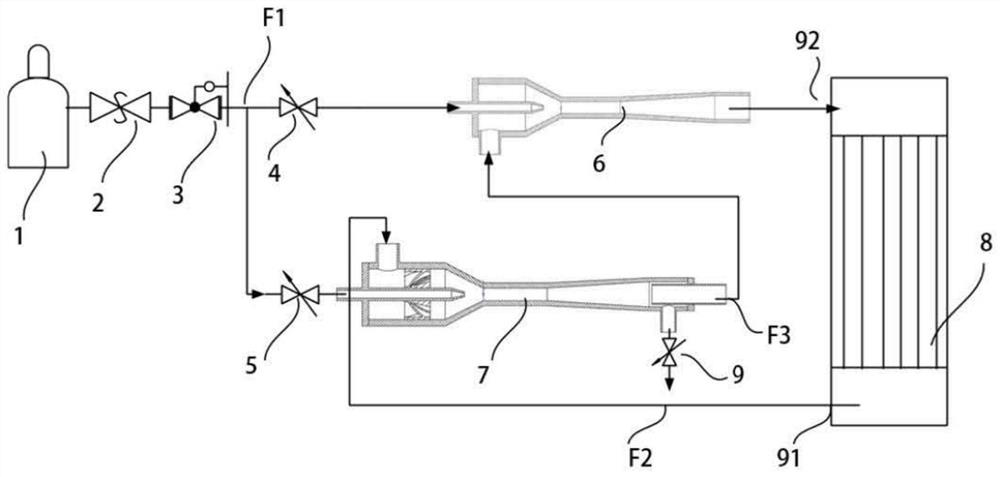

[0054] System components include: hydrogen cylinder 1, stop valve 2, pressure reducing valve 3, second hydrogen injection valve 5, first hydrogen injection valve 4, ejector 6, gas-water separation assembly 7, fuel cell stack 8, drain valve 9 . The battery stack inlet 92 and the battery stack outlet 91 . High-pressure fresh hydrogen F1, the gas-liquid mixture F2 discharged from the stack, and the gas F3 from which the liquid droplets are separated. The structure of the ejector separator includes a nozzle 71 , a main body 72 , a swirl vane 73 , a gas-liquid mixture inlet 74 , an exhaust pipe 75 and a drain pipe 76 .

[0055] image 3 , is the system proposed in this scheme. The high-pressure hydrogen cylinder 1 stores high-pressure hydrogen as fuel for the fuel cell stack 8, and after passing through the cut-off safety valve 2 and the pressure reducing valve 3, it is supplied to the ejector 6 (or ejector separator) fresh hydrogen F1 with a certain pressure value. The ejecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com