Flexible connection copper foil with good heat dissi'pation

A soft connection and copper foil technology, applied in the field of soft connection, can solve the problems affecting the normal use of soft connection copper foil, poor heat dissipation, etc., and achieve the effect of simple structure, good heat dissipation effect, and easy bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

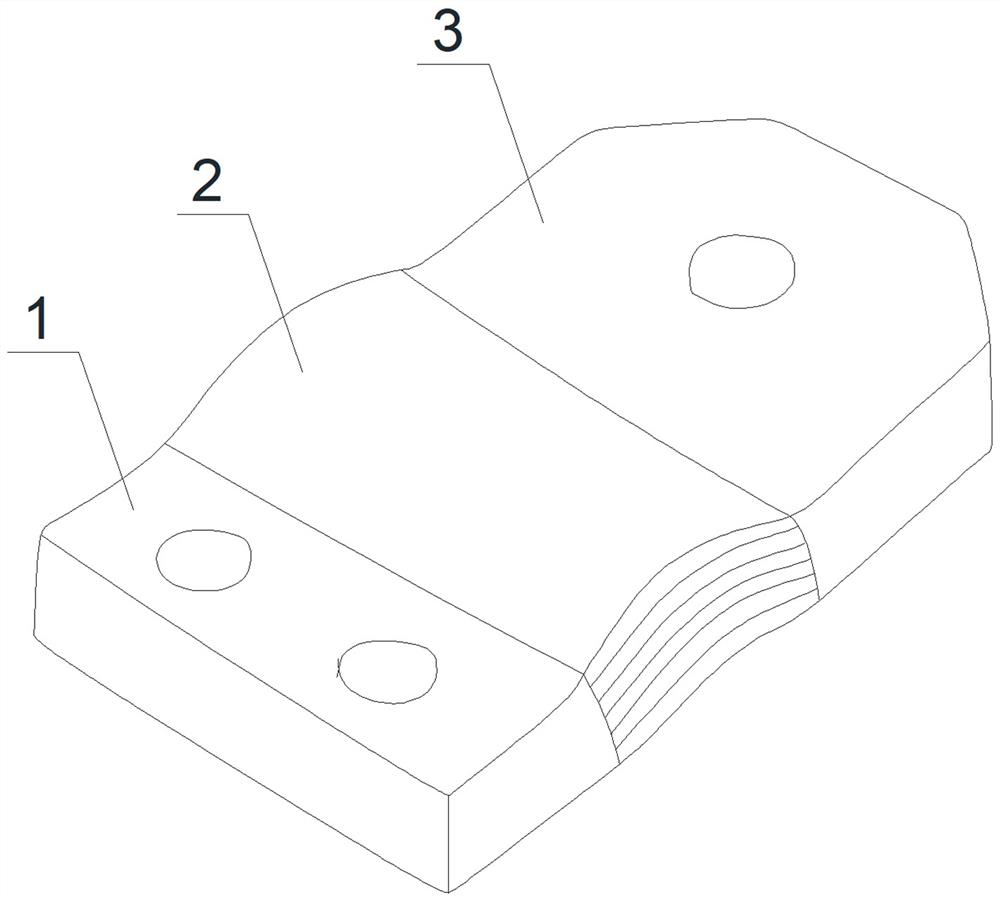

[0019] like figure 1 As shown, a flexible connection copper foil with good heat dissipation includes a main connecting piece 1, the right end of the main connecting piece 1 is connected to the first copper foil laminate group 2, and the right end of the first copper foil laminate group 2 is connected to the first connection Sheet 3, the main connecting sheet 1, the first copper foil laminate group 2 and the first connecting sheet 3 are on the same straight line. Both the main connecting piece 1 and the connecting piece 3 for the first time are provided with connecting holes, which can be directly connected with the connecting column and slightly fixed, which is convenient for installation. Both the main connecting piece 1 and the primary connecting piece 3 are pressed together by copper foil laminations, and formed by pressure welding by molecular diffusion welding.

[0020] The first copper foil lamination group 2 includes several copper foil laminations stacked and arranged...

Embodiment 2

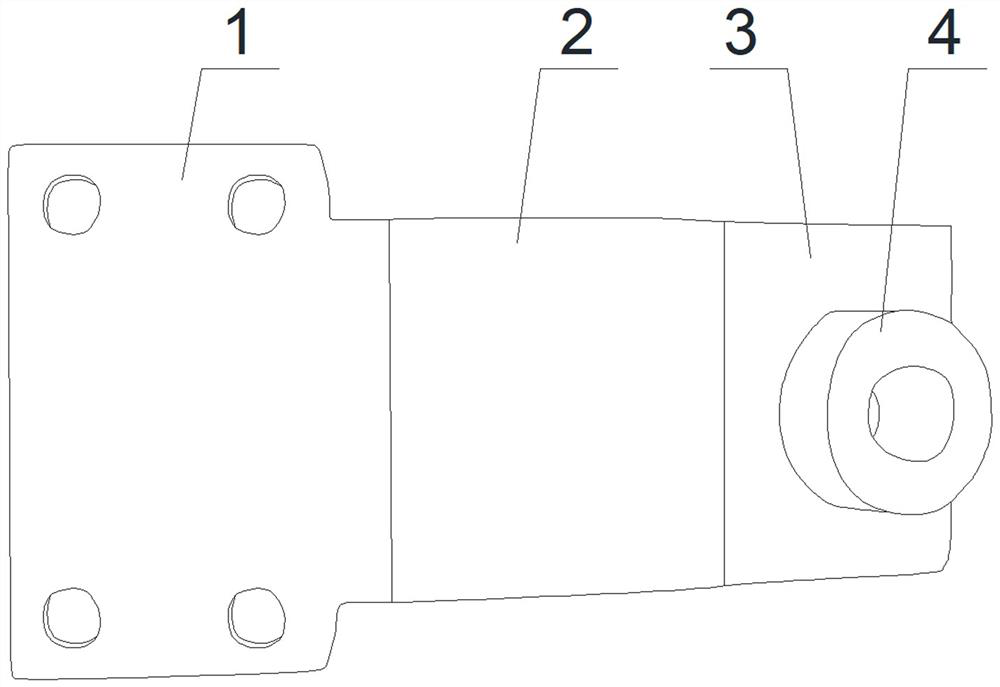

[0022] like figure 2 As shown, a flexible connection copper foil with good heat dissipation includes a main connecting piece 1, the right end of the main connecting piece 1 is connected to the first copper foil laminate group 2, and the right end of the first copper foil laminate group 2 is connected to the first connection Sheet 3, the main connecting sheet 1, the first copper foil laminate group 2 and the first connecting sheet 3 are on the same straight line. Both the main connecting piece 1 and the connecting piece 3 for the first time are provided with connecting holes, which can be directly connected with the connecting column and slightly fixed, which is convenient for installation. Both the main connecting piece 1 and the primary connecting piece 3 are pressed together by copper foil laminations, and formed by pressure welding by molecular diffusion welding. The position corresponding to the connecting hole on the first connecting piece 3 is welded with the connectin...

Embodiment 3

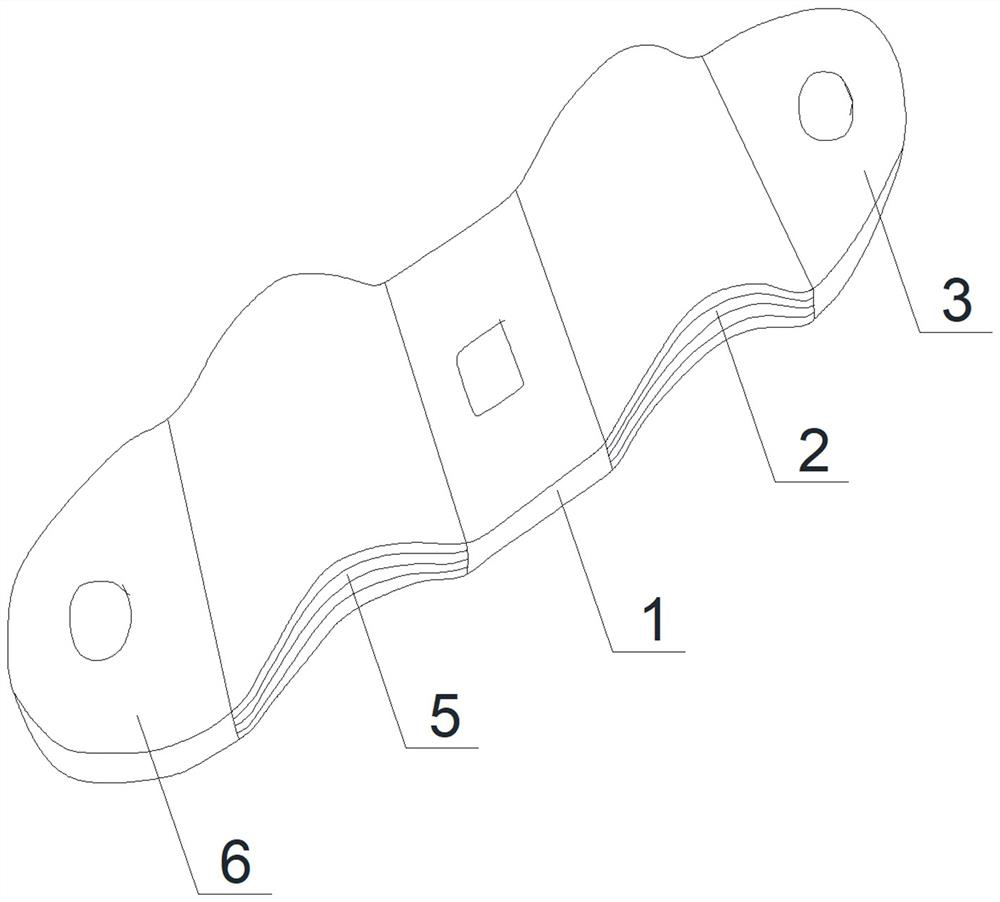

[0025] like image 3 As shown, a flexible connection copper foil with good heat dissipation includes a main connecting piece 1, the right end of the main connecting piece 1 is connected to the first copper foil laminate group 2, and the right end of the first copper foil laminate group 2 is connected to the first connection Sheet 3, the left end of the main connecting sheet 1 is connected to the second copper foil lamination group 5, the left end of the second copper foil lamination group 5 is connected to the second connecting sheet 6, the main connecting sheet 1, the first copper foil lamination group 2 , the first connection piece 3 , the second copper foil laminate group 5 and the second connection piece 6 are on the same straight line. The main connecting piece 1, the connecting piece 3 for the first time and the connecting piece 6 for the second time are all provided with connecting holes, which can be directly connected with the connecting column and slightly fixed, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com