Shield tunnel surrounding rock deformation advanced monitoring structure and monitoring method

A technology for surrounding rock deformation and shield tunneling, applied in the field of tunnels, can solve the problems of inability to feedback surrounding rock deformation data and low monitoring efficiency, and achieve the effects of being beneficial to data collection, improving service life and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

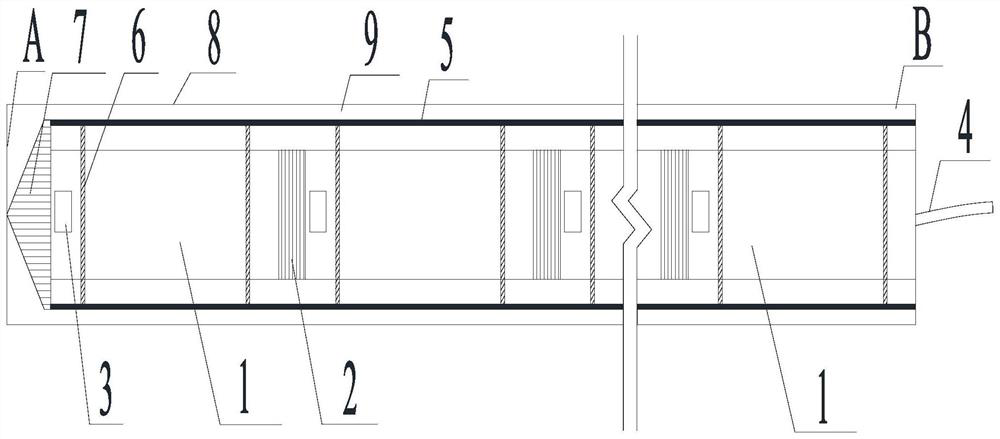

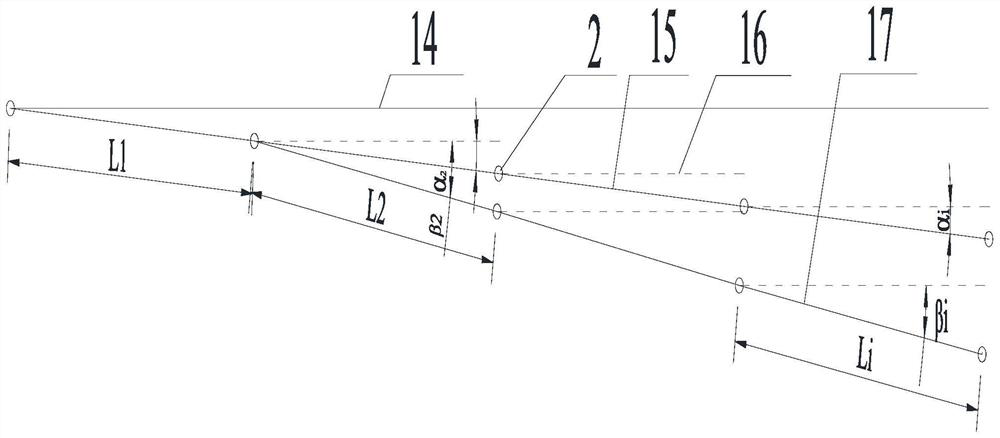

[0059] Such as figure 1 As shown, the present invention is a shield tunnel surrounding rock deformation advanced monitoring structure, including a monitoring body composed of several monitoring sections 1, flexible connecting sections 2 and angle sensing devices 3 located on the monitoring section 1, wherein the flexible connecting section 2 The two ends are respectively connected to the first section and the tail end of two adjacent monitoring sections 1, and the angle sensing device 2 is used to monitor the angle between the monitoring section 1 on it and the horizontal plane and the vertical plane.

Embodiment 2

[0061] On the basis of Embodiment 1, the flexible connecting section 2 respectively connects each adjacent monitoring section 1 with bolts in turn, and connects the cables of the angle sensing devices 3 in each adjacent monitoring section 1 during connection. In order to further fix the position of the monitoring body and protect it, the head end of the monitoring section 1 close to the A end is connected with a guide head 7 with a pointed cone at one end by bolts, and when the monitoring body is installed through the guide head 7 , play a guiding role.

[0062] Moreover, a flexible sleeve 5 is sleeved on the monitoring section 1 and the flexible connecting section 2, and the flexible sleeve 5 sleeves the monitoring main body therein. At this time, the guide head 7 is connected to the end of the flexible sleeve 5 near the A end, and the gap between the guide head 7 and the flexible sleeve 5 is sealed with a sealant, and waterproof treatment is performed to prevent the filler f...

Embodiment 3

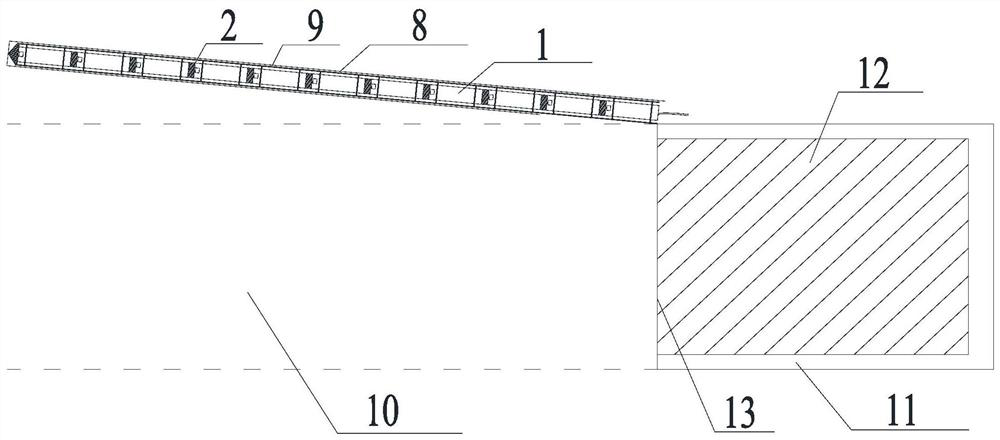

[0065] Such as figure 2 As shown, on the basis of embodiment 2, when in use, the monitoring main body is located in the advance borehole 8, and the advance borehole 8 is an obliquely upwardly inclined borehole above the unexcavated section 10 in the surrounding rock. The advance borehole 8 and The angle between the horizontal straight lines is 15°, the length of the advanced drilling 8 is 10m, and the length of a monitoring section 1 is 40cm.

[0066] In Embodiment 2, the monitoring body with the flexible sleeve 5 and the lead wire head 7 is placed in the advanced borehole 8, and after placement, a filler layer 9 for fixing the monitoring body is filled between the advanced borehole 8 and the monitoring body, The filler layer 9 of the device is cement mortar. After fixing, since the monitoring section 1 is a hollow steel pipe inside, the angle sensing device 2 is located inside the steel pipe. The angle sensing device 2 includes a first angle sensor and a second angle sensor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com