Exhaust gas purification system

An exhaust gas purification system and exhaust gas technology, applied in the field of purification systems, can solve problems such as poor exhaust gas purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Before the present invention is described in detail, it should be noted that in the following description, similar components are denoted by the same numerals.

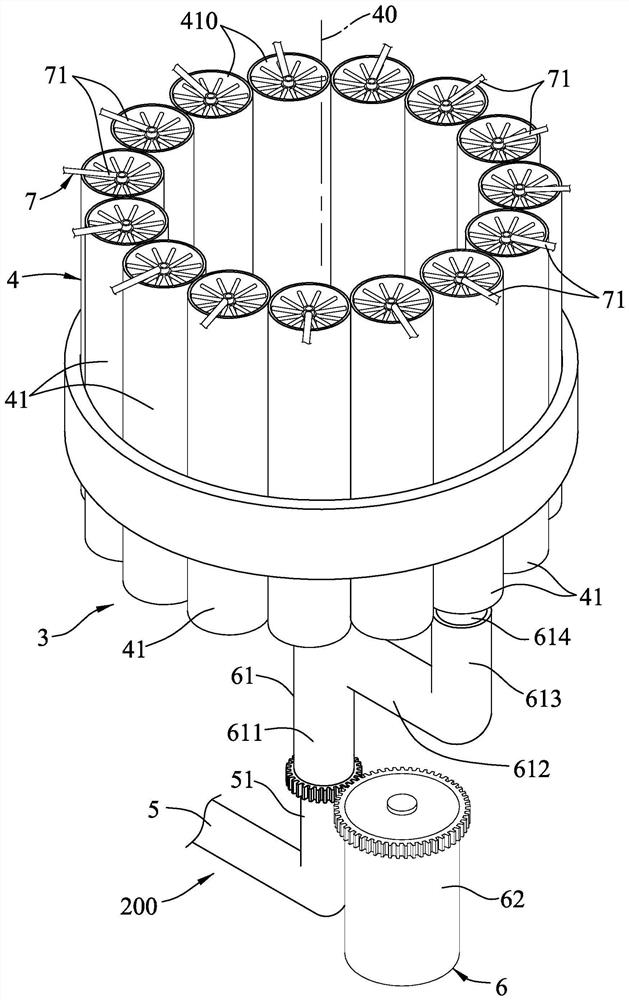

[0025] refer to figure 1 , 2 3. The first embodiment of the exhaust gas purification system 200 of the present invention is suitable for installation in an exhaust gas generating device (not shown in the figure), and can be used to purify and discharge the exhaust gas discharged from the exhaust gas generating device. The exhaust gas purification system 200 includes an exhaust gas capture mechanism 3 connected to the exhaust gas generating equipment, a purification equipment 7 installed on the exhaust gas capture mechanism 3, and a signal connection between the exhaust gas capture mechanism 3 and the purification equipment. 7 of the control device 8 (shown in Figure 4 ).

[0026] The exhaust gas capture mechanism 3 includes a circulation capture unit 4, a smoke exhaust pipe 5 connected to the exhaust gas ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com