Anti-release spoke

An anti-loosening, functional technology, applied in spoked wheels, wheels, transportation and packaging, etc., can solve problems such as inconvenient adjustment, dents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

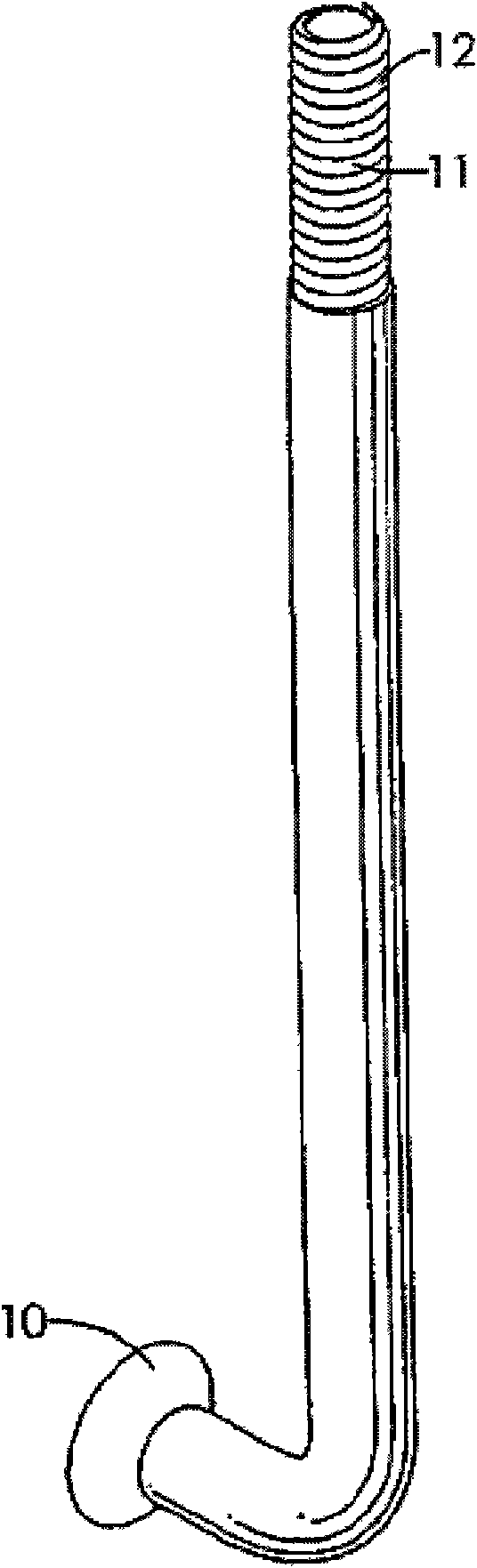

[0014] refer to figure 1 As shown, the spoke with anti-loosening function of the present invention is a long rod body with a bend formed at one end and a flange formed at the end end to form an engaging end 10, and the rod surface at the other end of the spoke A thread portion 11 is formed, and an anti-loosening plastic 12 is coated on the thread portion 11 .

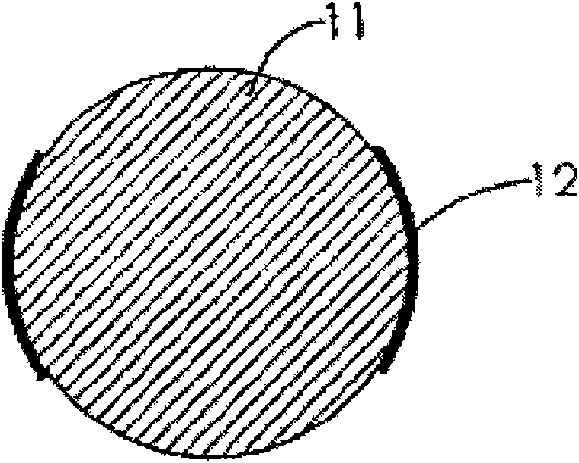

[0015] Below further enumerates the preferred embodiment that several anti-loosening plastics 12 are coated on the thread portion 11, to describe the spoke of the tool anti-loosening function of the present invention, refer to figure 2 As shown, it is an embodiment of the present invention, wherein the anti-loosening plastic 12 is coated on the arc surfaces on opposite sides of the circumference of the thread portion 11, and they are separated from each other with a distance.

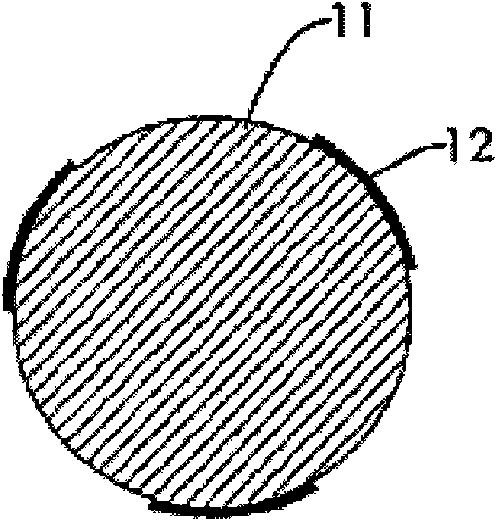

[0016] see further image 3 As shown, it is another preferred embodiment of the present invention, wherein the anti-loosening plastic 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com