Integrated gas mixing structure, combustor and stove

An integrated, burner technology, used in gas fuel burners, burners, combustion methods, etc., can solve the problems of waste of flue gas heat and insufficient burner combustion, and achieve the effect of reducing external emissions and improving thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

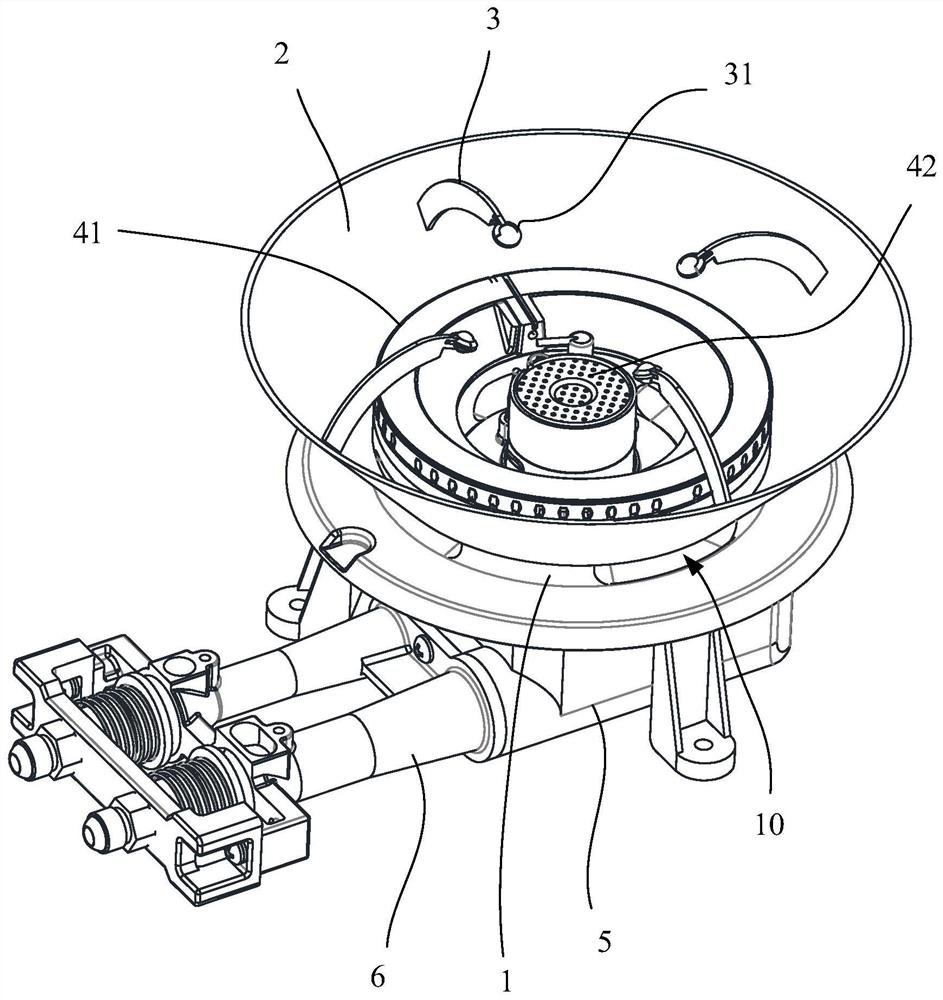

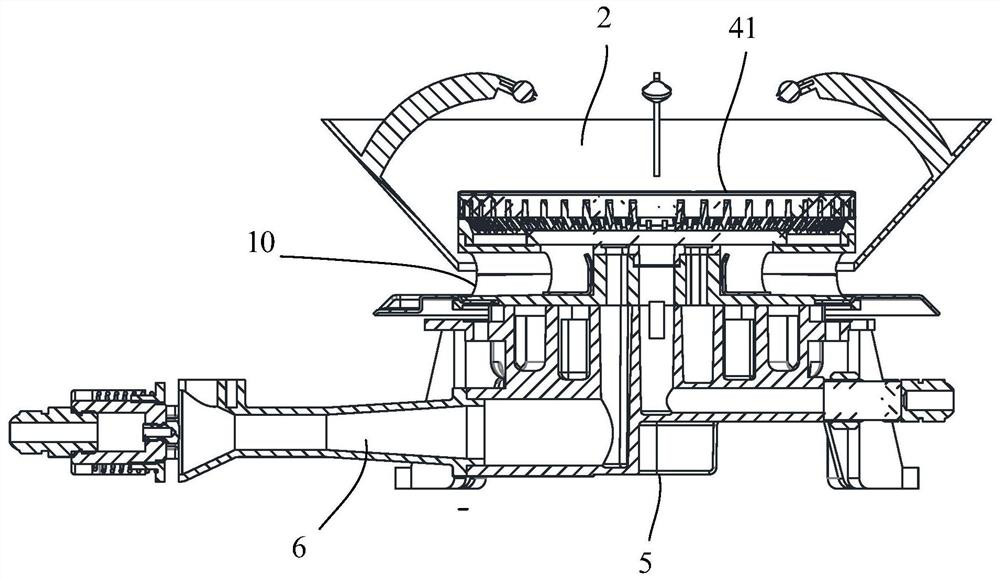

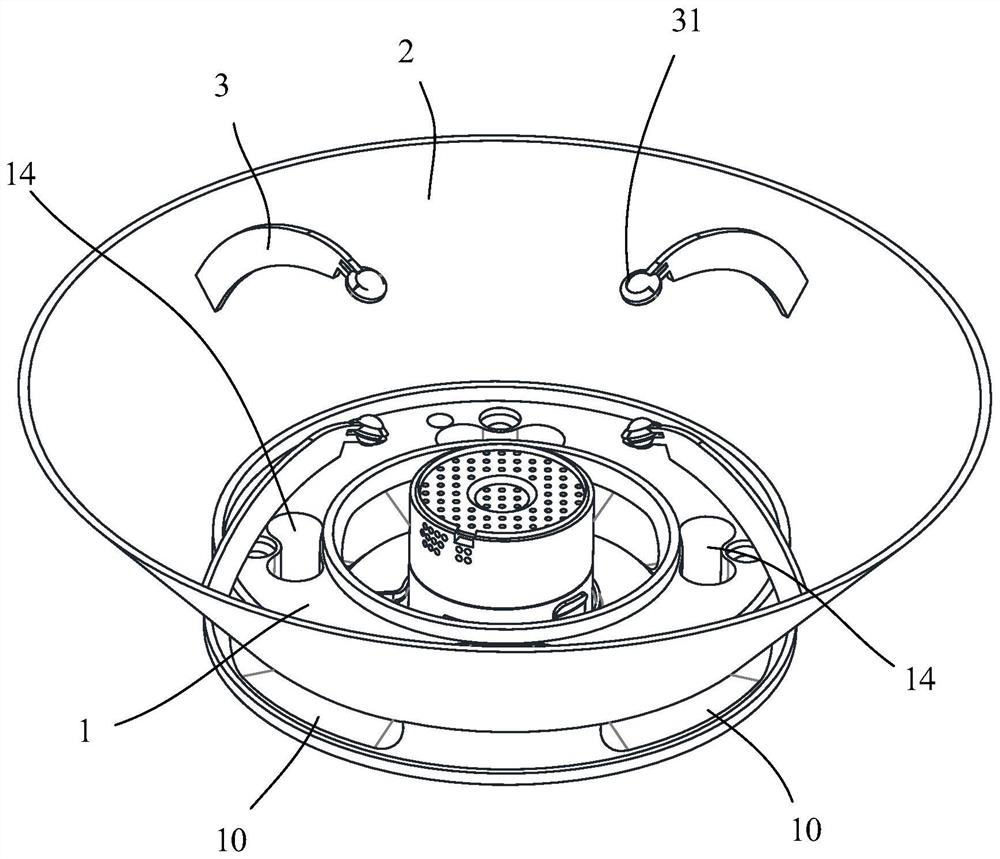

[0033] Such as Figure 1-Figure 6 As shown, the present invention discloses an integrated gas mixing structure. The integrated gas mixing structure includes a gas mixing chamber 1. A secondary air inlet 10 is arranged on the outer ring surface of the gas mixing chamber 1. The secondary air inlet 10 is connected to the mixing chamber. The outer surface and interior of the gas chamber 1. Such as Figure 1-Figure 6 As shown, the integrated air mixing structure of the present invention also includes an energy gathering cover 2, which is connected to the outer surface of the air mixing chamber 1, wherein the height of the lower edge of the energy gathering cover 2 is between the secondary air inlet 10 Between the height of the upper edge 101 and the lower edge 102 of the inlet, and in the height direction of the secondary air inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com