A hanging basket for highway bridge construction

A technology for highway bridges and frames, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. It can solve problems that affect the construction safety of workers, tilting of hanging baskets, and different moving speeds, so as to facilitate normal activities and ensure construction safety. The effect of reducing the content of burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] as attached figure 1 to attach Figure 5 Shown:

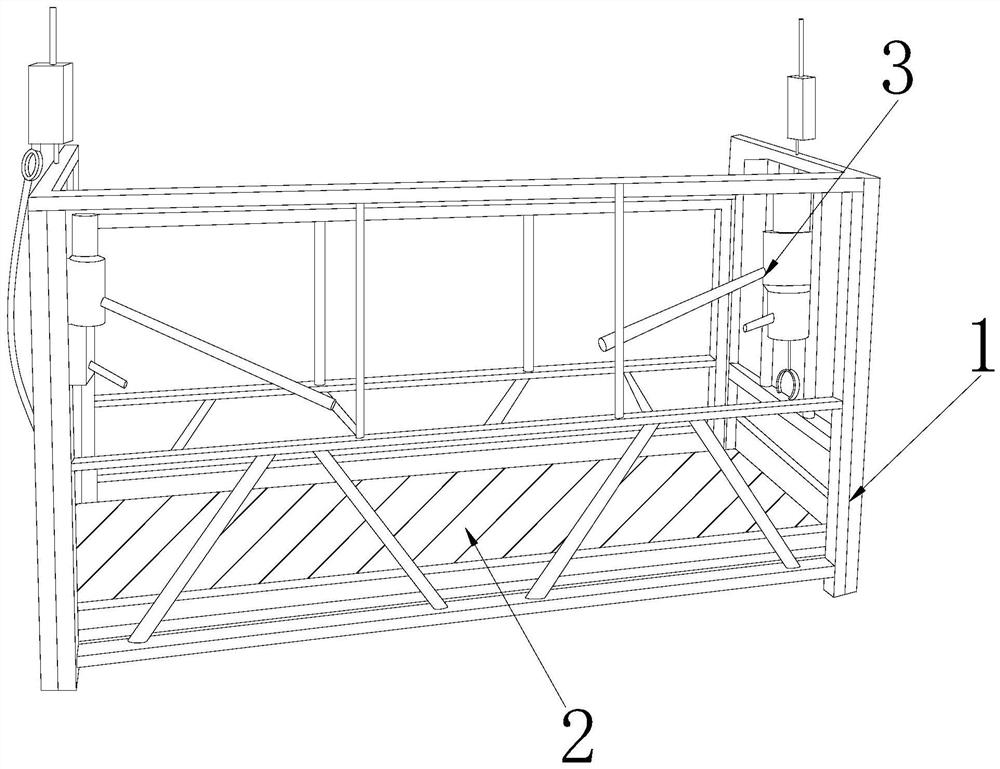

[0028] The invention provides a hanging basket for highway and bridge construction, the structure of which includes a frame 1, a pedal 2, and a lifting mechanism 3, the pedal 2 is fixed on the inner bottom of the frame 1, and the lifting mechanism 3 is respectively installed on both sides of the frame 1.

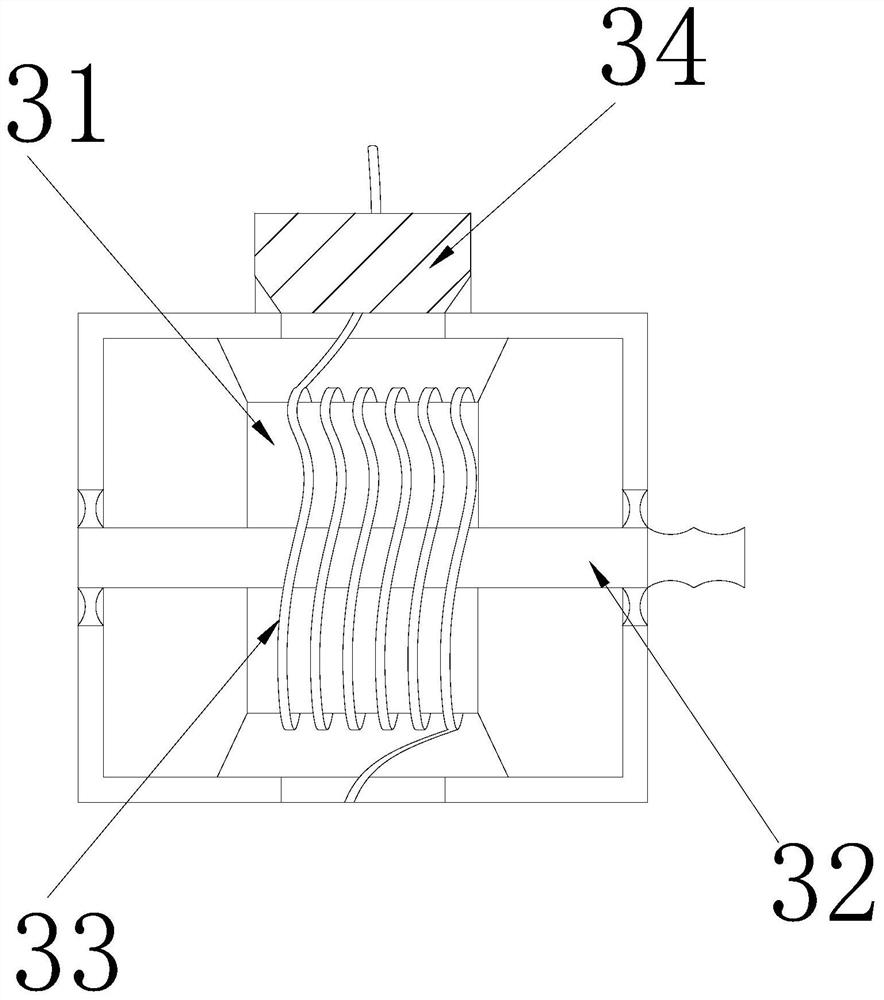

[0029] The lifting mechanism 3 includes a slide rail 31, a rotating shaft 32, a steel rope 33, and a top block 34. The sliding rail 31 is located in the middle of the lifting mechanism 3, the rotating shaft 32 is located inside the slide rail 31, and the steel rope 33 runs through The upper and lower sides of the lifting mechanism 3 are movably coordinated with the rotating shaft 32 , and the top block 34 is fixed on the top of the lifting mechanism 3 .

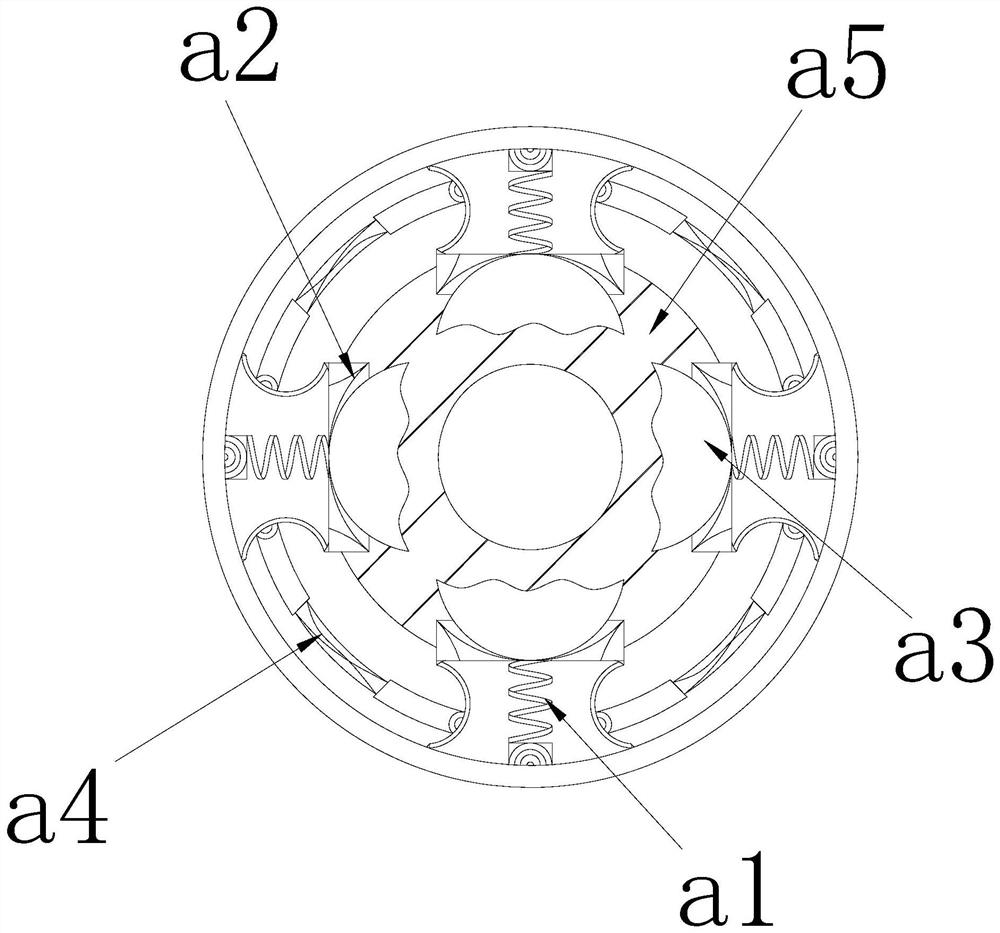

[0030] Wherein, the jacking block 34 includes a pushing block a1, a connecting block a2, a clearing block a3, a reset rod a4, and a collecting block a5, the pushing...

Embodiment 2

[0036] as attached Image 6 to attach Figure 8 Shown:

[0037] Wherein, the collection block a5 includes a top board r1, a collection chamber r2, and a side block r3, the top board r1 is fixed on both sides of the center of the collection block a5, and the collection chamber r2 is located inside the collection block a5 and is located on the top board r1 Below, the side blocks r3 are respectively installed in the collection chamber r2 close to the middle of the collection block a5, and the top plate r1 is inclined from both sides of the middle of the collection block a5, and has a smooth surface, which is beneficial to reduce friction and reduce resistance to speed up falling The burrs slide into the collection chamber r2 for collection.

[0038]Wherein, the side block r3 includes a limit block t1, a bump t2, and an opening t3, the limit block t1 is fixed on the inner wall of the side block r3, the bump t2 is fixed on the left side of the side block r3, and the opening t3 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com