Infrared MEMS bridge column structure and process method

A process method and technology of bridge columns, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of bridge columns not being etched clean, and achieve easy removal, prevention of oxidation, and prevention of residues Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

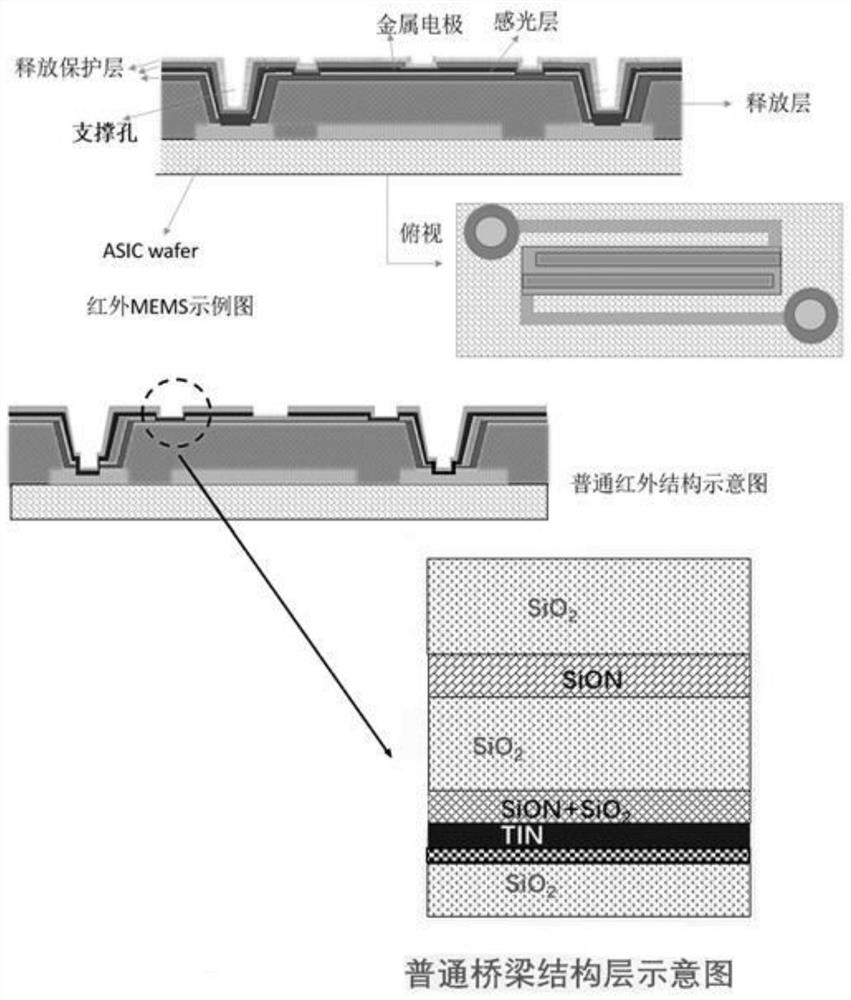

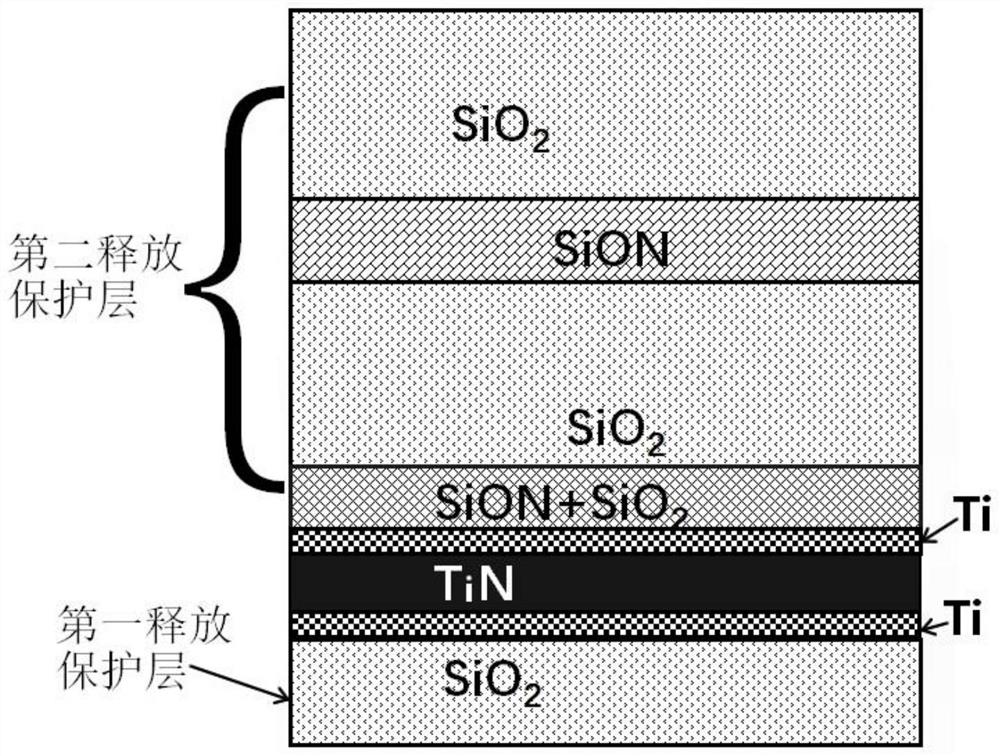

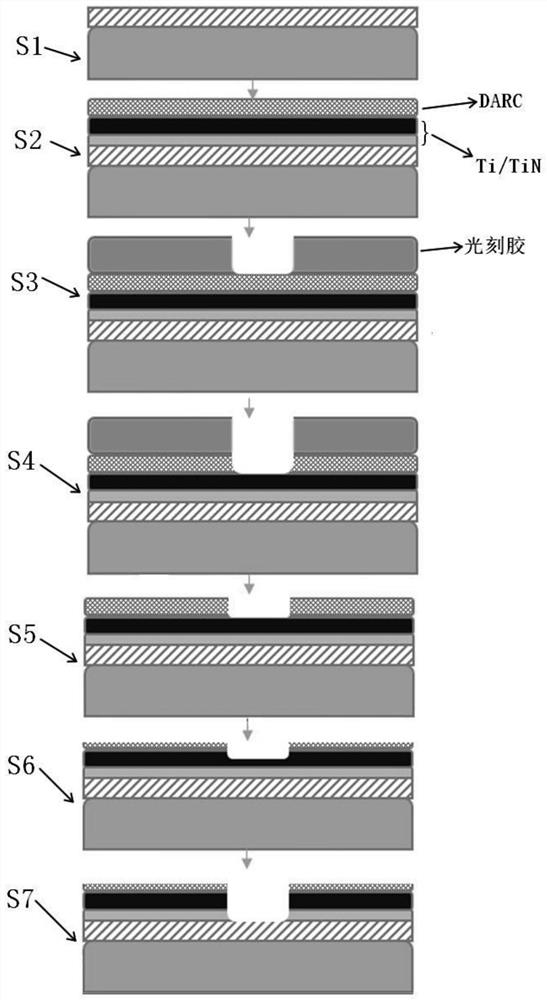

[0048] The infrared MEMS bridge column structure of the present invention mainly improves the film layer of the bridge column of the MEMS structure. Such as figure 1 As shown in , the figure is a cross-sectional view of an infrared MEMS structure, including a support hole structure, a bridge column structure, and a film layer structure outside the bridge column area. The support holes are located at both ends, and the MEMS is between the two support holes. structure, figure 1The dotted circle in is the bridge column structure area of the infrared MEMS structure. A traditional bridge column film layer includes a first release protection layer, a metal dielectric layer, and a second release protection layer. The metal dielectric layer includes TiN and Ti layers. In the traditional process, in the process of etching the film layer to form bridge columns, when removing the photoresist and etching the DARC layer, TiN The resistance of the Ti layer to the etched oxygen ions is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com