A kind of slagging device and method for feeding steel belt of gas shielded continuous casting crystallizer

A continuous casting mold and gas shielding technology is applied in the field of slag discharge devices for feeding steel strips into a gas shielded continuous casting mold. The effect of molten steel oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

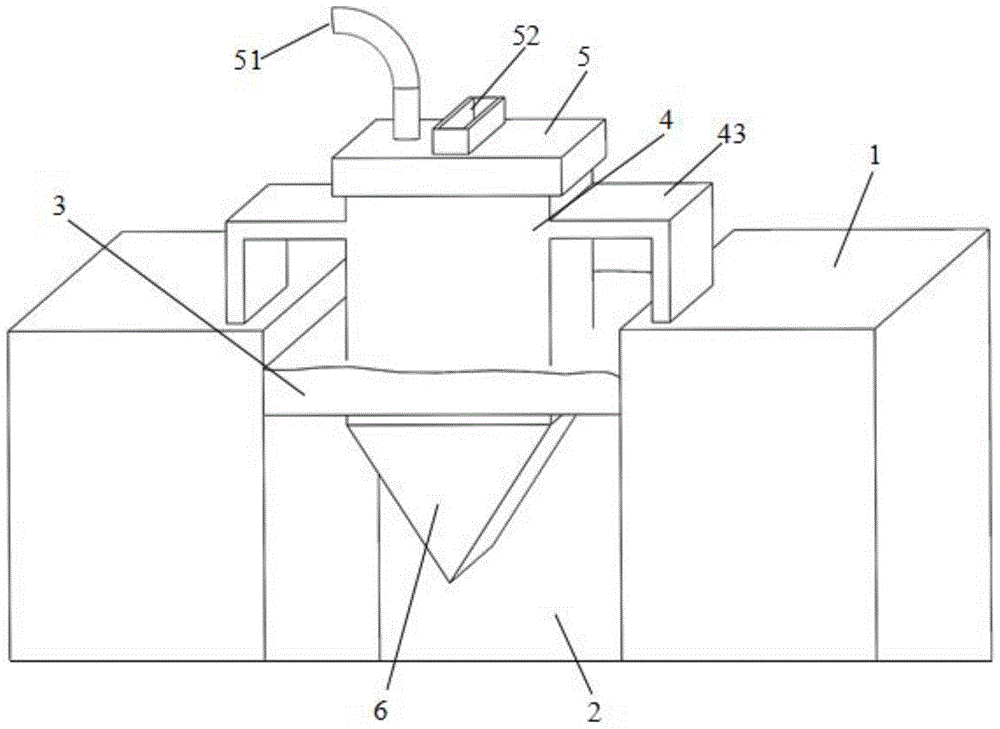

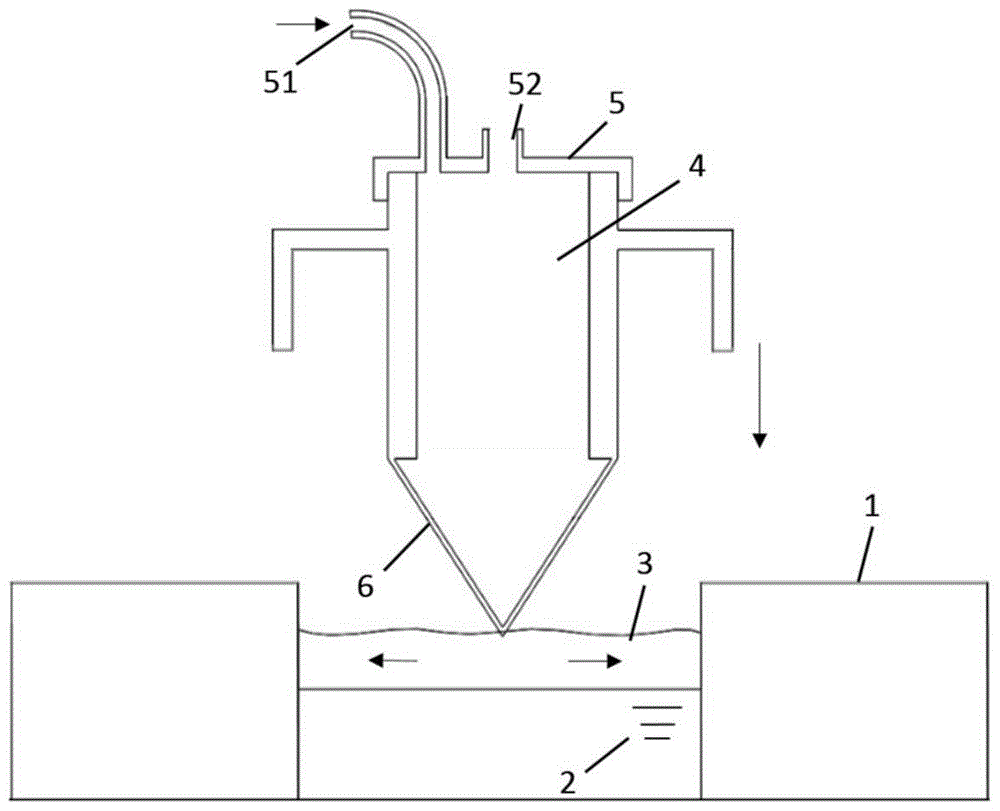

[0030] Such as figure 1 , the slagging device of the present invention for feeding the steel belt into the gas-protected continuous casting mold is used in the continuous casting mold 1, the mold 1 has a high-temperature molten steel 2, the top surface of the molten steel 2 has a mold slag 3, and the slag is discharged The device includes a hollow cover body 4, an upper cover 5 is provided on the top of the cover body 4, and a steel slag discharge member 6 is connected to the bottom of the cover body 4.

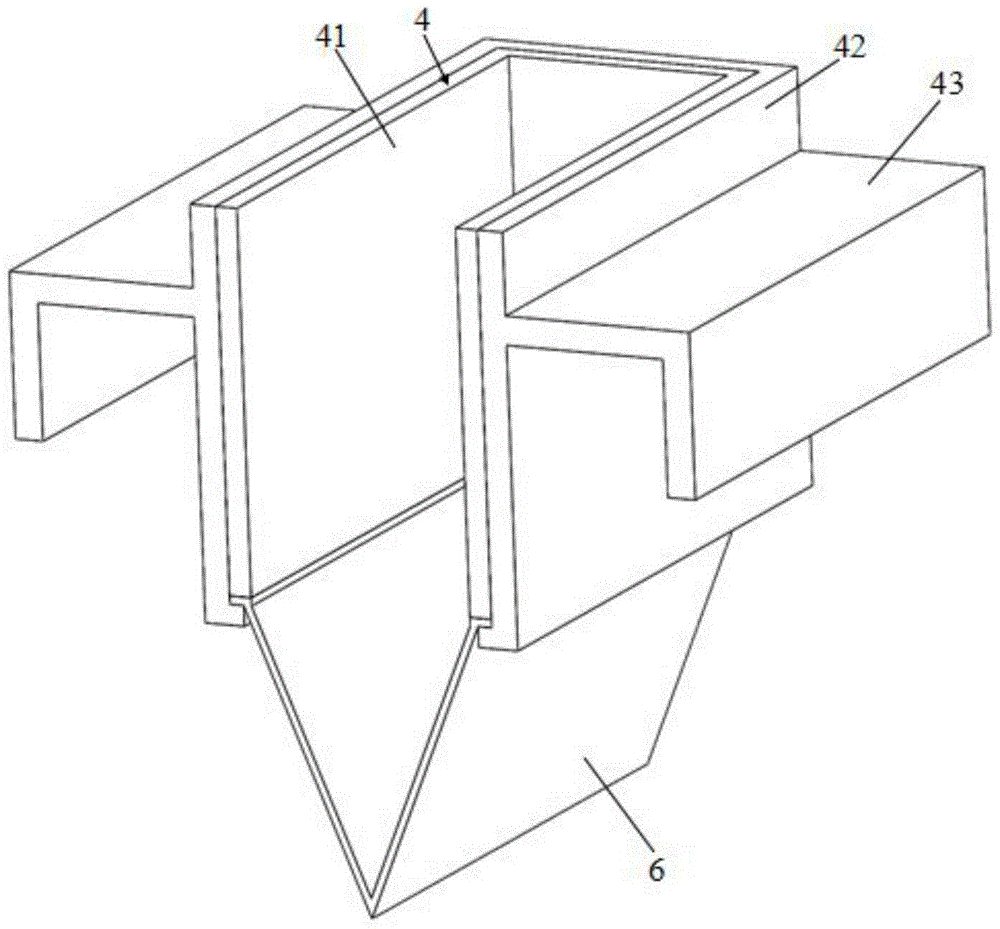

[0031] Such as figure 2 , the cover body 4 is made of refractory material, including an inner sleeve 41 and an outer sleeve 42, and the steel slag discharge member 6 is clamped between the bottom of the inner sleeve 41 and the bottom of the outer sleeve 42, so that the steel discharge The slag piece 6 is installed on the cover bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com