Bicycle carrying frame forming machine

A technology for forming machines and bicycles, applied to bicycle accessories, feeding devices, manufacturing tools, etc., can solve the problems of complex operation and low efficiency, and achieve the effect of reducing the difficulty of operation and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

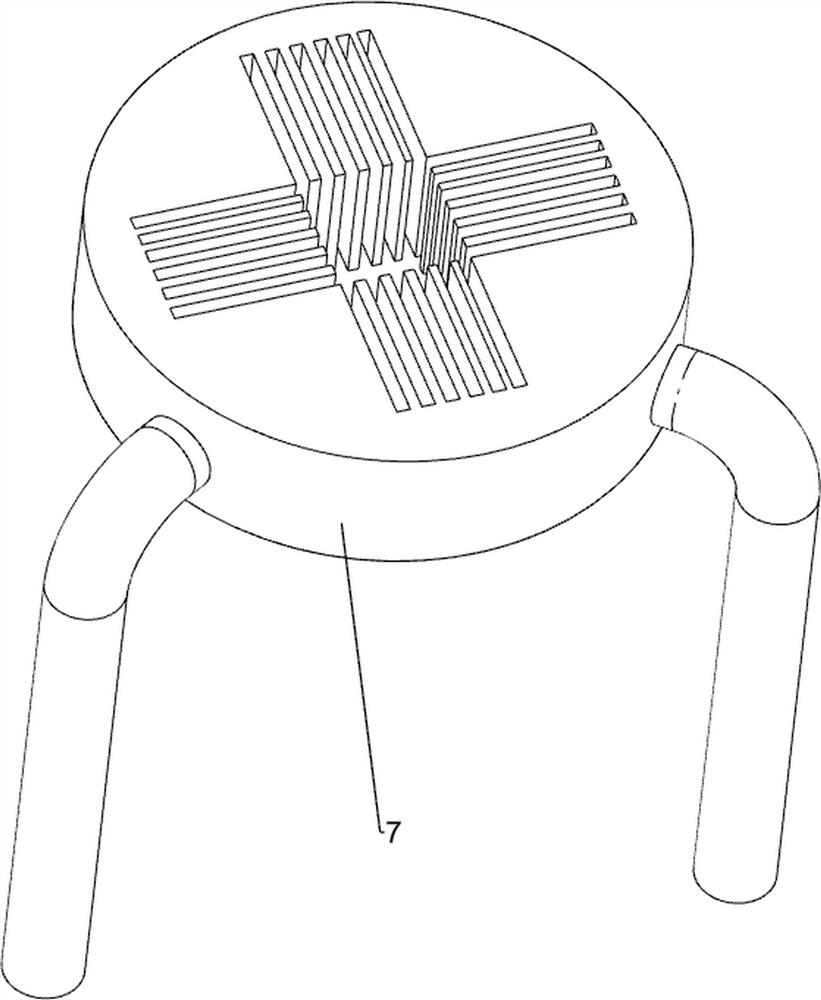

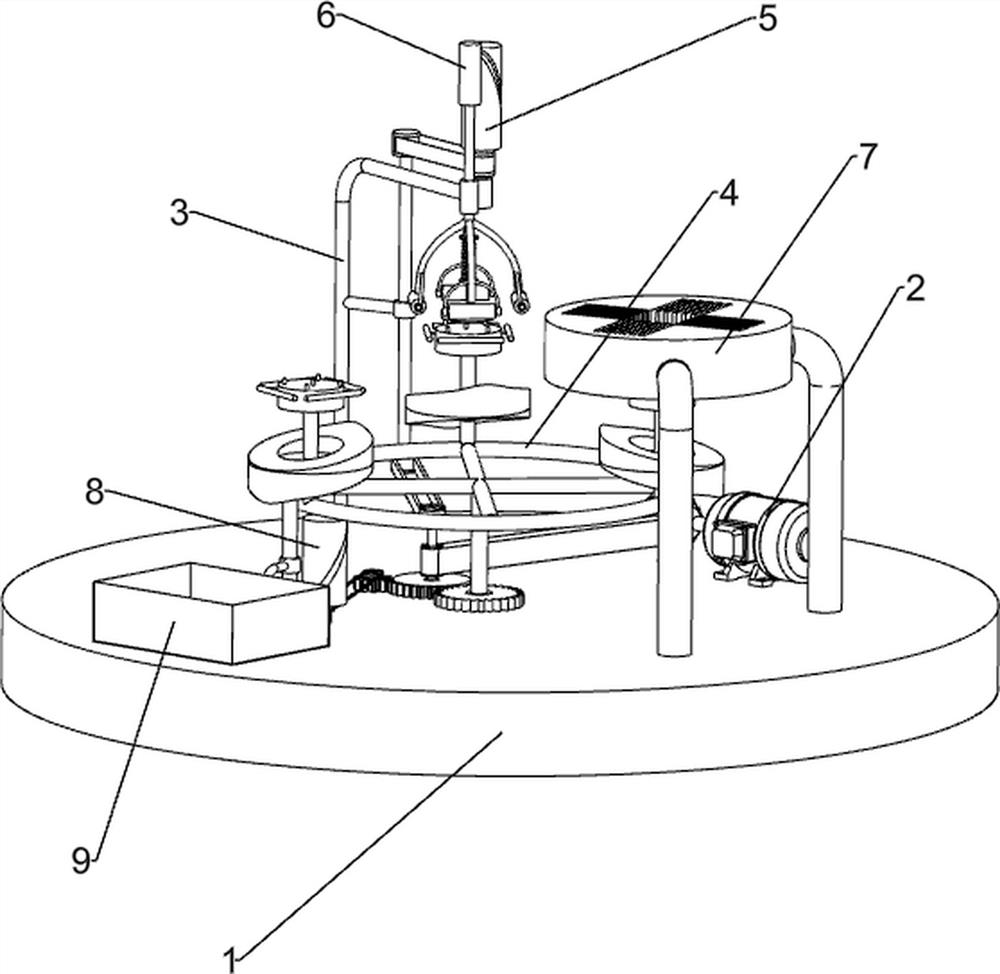

[0027] A bicycle loading frame forming machine, such as Figure 1-4 and Figure 7 As shown, it includes a base plate 1, a motor 2, a long rod 3, a rotating mechanism 4, a pressing mechanism 5, a bending mechanism 6 and a blanking block 7. The motor 2 is installed on the right side of the top of the base plate 1, and the rear of the top of the base plate 1 A long rod 3 is installed on the side, a rotating mechanism 4 is connected in the middle of the top of the bottom plate 1, a bending mechanism 6 is installed on the long rod 3, a pressing mechanism 5 is connected between the bending mechanism 6 and the rotating mechanism 4, and the bending mechanism 6 is located in the Above the rotating mechanism 4, a blanking block 7 is connected to the top front side of the bottom plate 1.

[0028] The rotating mechanism 4 includes a first sleeve 41, a bevel gear set 42, a first rotating shaft 43, a second sleeve 44, a first belt device 45, a missing gear 46, a first spur gear 47, a turnt...

Embodiment 2

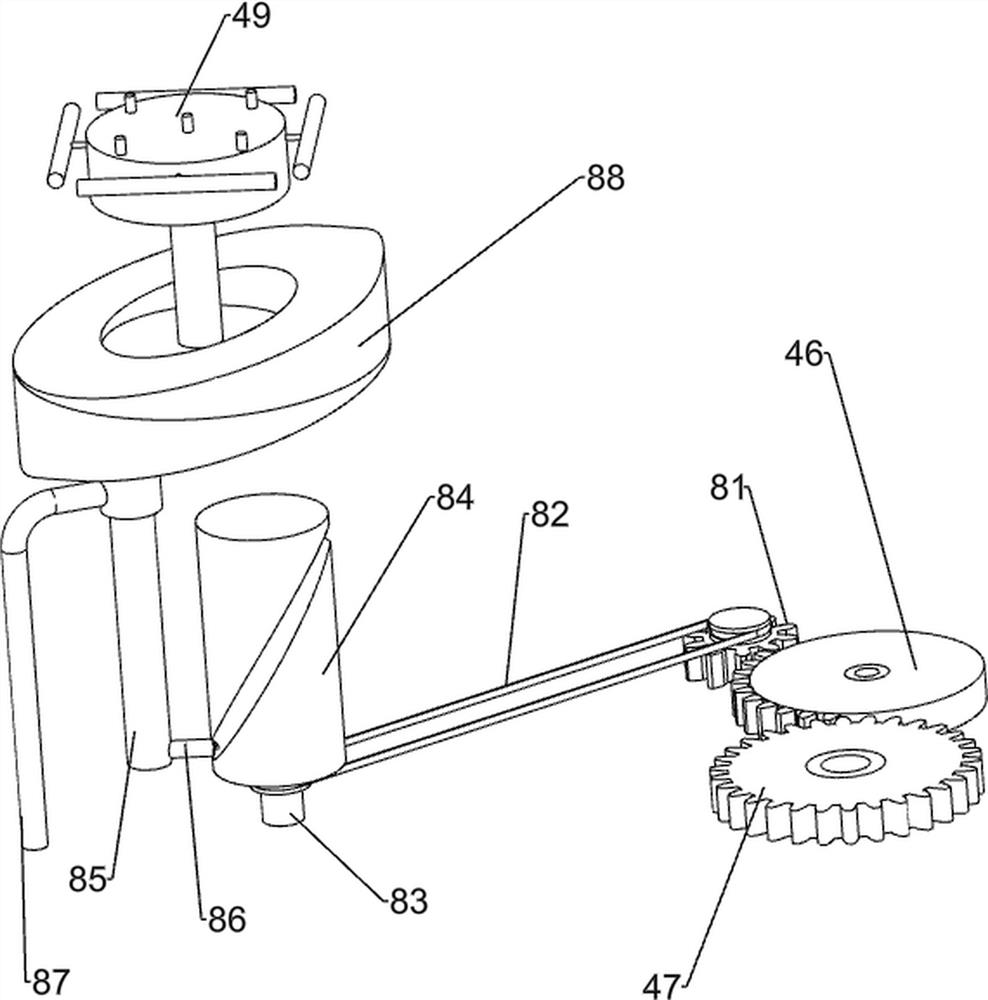

[0033] On the basis of Embodiment 1, such as figure 1 and Figure 5-6 As shown, the ejection mechanism 8 is also included, and the ejection mechanism 8 includes the second spur gear 81, the fourth belt device 82, the fourth rotating shaft 83, the second roller 84, the ejector column 85, the second guide column 86, the Four sets of columns 87 and push blocks 88, the middle of the top of the base plate 1 is connected with the second spur gear 81 in a rotational manner, the second spur gear 81 meshes with the missing gear 46, and the left side of the top of the base plate 1 is connected with the fourth set of columns 87 and the second spur gear. Four rotating shafts 83, the fourth sleeve column 87 is fixedly connected with the base plate 1, the fourth rotating shaft 83 is connected with the base plate 1 in a rotational manner, a fourth belt device 82 is connected between the fourth rotating shaft 83 and the second spur gear 81, and the fourth rotating shaft 83 The top is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com