A low-voltage torrent coil oil-immersed transformer

An oil-immersed transformer, torrential winding technology, applied in the field of transformers, can solve the problems of fast flow speed, low viscosity of transformer oil, affecting the safety of transformers, etc., and achieve the effect of slowing down the flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

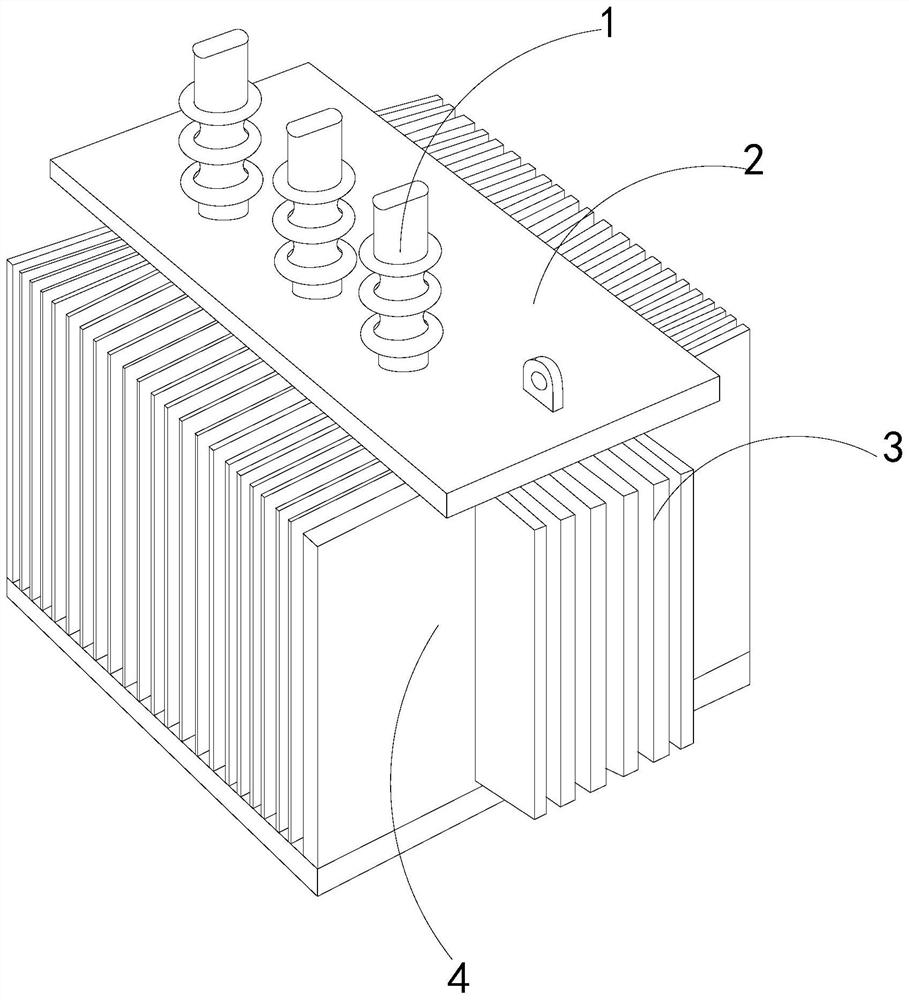

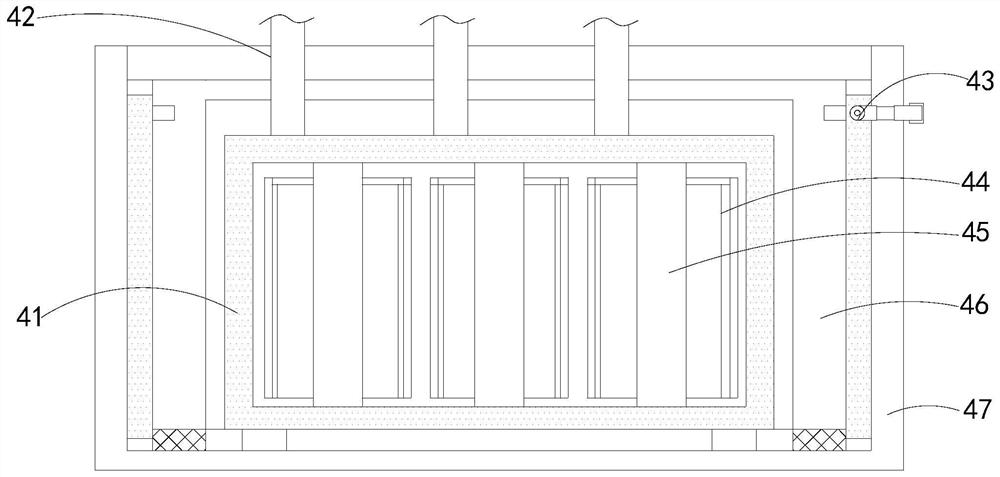

[0027] Such as Figure 1-Figure 6 Shown:

[0028] The present invention is a low-voltage torrent coil oil-immersed transformer, the structure of which includes a terminal rod 1, a fixed plate 2, a radiator 3, and a resistance mechanism 4. The terminal rod 1 communicates with the fixed plate 2, and the fixed plate 2 is installed On the surface of the resistance mechanism 4, the heat sink 3 is embedded on the side of the resistance mechanism 4, and the resistance mechanism 4 is provided with a fixed frame 41, a metal rod 42, a moving mechanism 43, an electric coil 44, a magnetic rod 45, and a filling groove 46. Outer shell 47, the electric coil 44 surrounds the outer side of the magnetic rod 45, the upper and lower ends of the magnetic rod 45 are embedded in the fixed frame 41, and the lower end of the fixed frame 41 is embedded in the inner lower end of the outer shell 47 , the filling groove 46 is located inside the casing 47, the moving mechanism 43 is installed inside the...

Embodiment 2

[0036] Such as Figure 7-Figure 9 Shown:

[0037] Wherein, the pressing mechanism a1 is provided with a spring a11, a rubber ring a12, and a fixed shaft a13. The rubber ring a12 is attached to the outside of the spring a11, and the left and right ends of the spring a11 are embedded in the inside of the fixed shaft a13. The fixed shaft a13 is embedded in the upper end of the drainage plate a2, and the middle of the fixed shaft a13 is a fixed shaft. There are four fixed shafts a13, which are divided into two groups. There is a gap between each group, so that the spring When a11 is bent under force, the gap between the fixed shafts a13 becomes larger, so that the sediment is deposited, and the sediment is prevented from flowing when the oil is convected, so as to prevent the convection velocity from being affected.

[0038] Wherein, the storage mechanism 432 is provided with a semicircular block p1, a support rod p2, a placement groove p3, a blocking plate p4, a sealing plate p5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com