Device and a method for detecting geometric parameters of steel bar weld joint

A technology of geometric parameters and detection devices, applied in the direction of measuring devices, optical devices, image data processing, etc., can solve the problems of large human error, low efficiency, inconvenient operation of welding inspection ruler, etc., and achieve high precision and real-time performance , Guarantee the effect of measurement accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

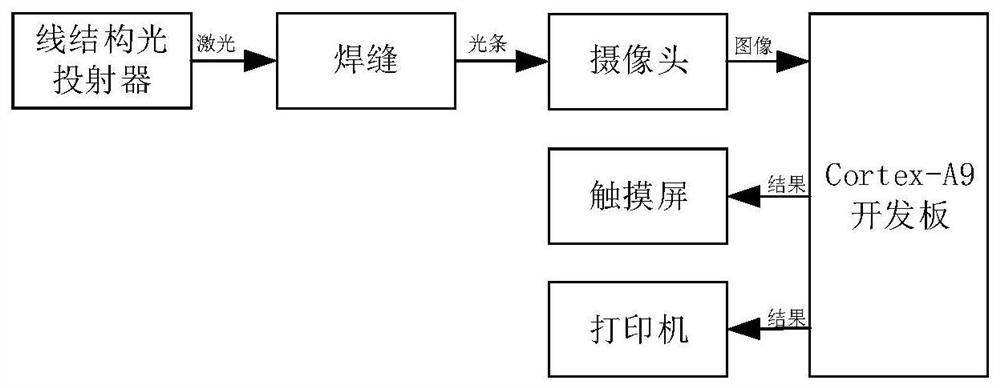

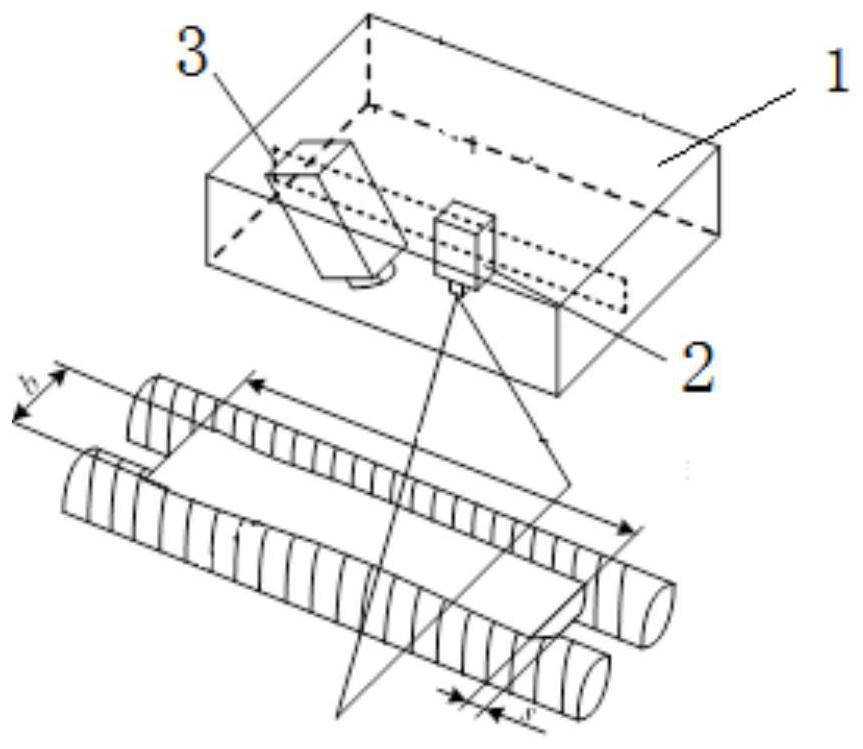

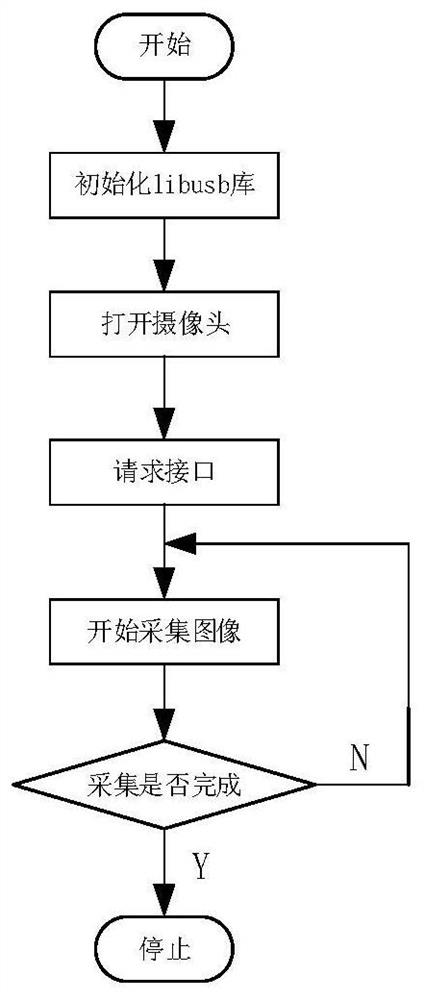

[0047] see figure 1 and image 3 , according to the present invention, the embedded reinforcement weld image detection scheme utilizing line structured light, the measurement model based on line structured light reinforcement weld active vision and the method for obtaining weld parameters comprise the following steps: Step 1, using image acquisition The module acquires weld images in real time;

[0048] Step 2, preprocessing the weld image obtained in step 1 and performing binarization processing on it, and using the gray square weighted threshold center of gravity method to extract the light bar center of the preprocessed weld image;

[0049] Step 3, calibrate the image acquisition module used in step 1, and then obtain the relationship between the image coordinate system and the world coordinate system;

[0050] Step 4, on the basis of the relatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com