System and method for tracing production line equipment by applying blockchain technology

A production line and blockchain technology, applied in the field of industrial production, can solve problems such as unrecorded products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment (1

[0071] Embodiment (1) system

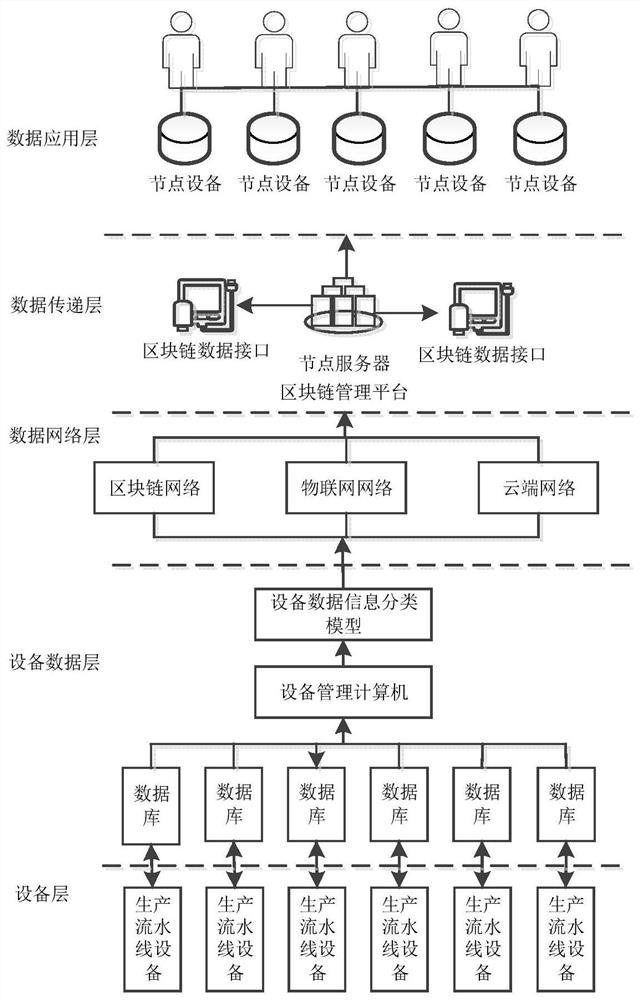

[0072] Such as figure 1 As shown, a system that applies blockchain technology to realize the traceability of production line equipment, the system includes:

[0073] The equipment layer is equipped with production line equipment, and the production line equipment includes at least controllers, robots, servo motors, sensors, frequency converters, solenoid valves, industrial cameras, instruments and meters or control cabinets;

[0074] The data entry layer, which is set on the assembly line, is used to write data into the operation of each process of the product on the production line and the use of accessories;

[0075] The device data layer is provided with a device management computer in it, and the device management computer is connected with a database storing multiple data types, and the database at least includes a DB2 database, an oracle database, an Informix database, a Sybase database, a SQL Server database, and a PostgreSQL database or...

Embodiment (2

[0081] Embodiment (2) method

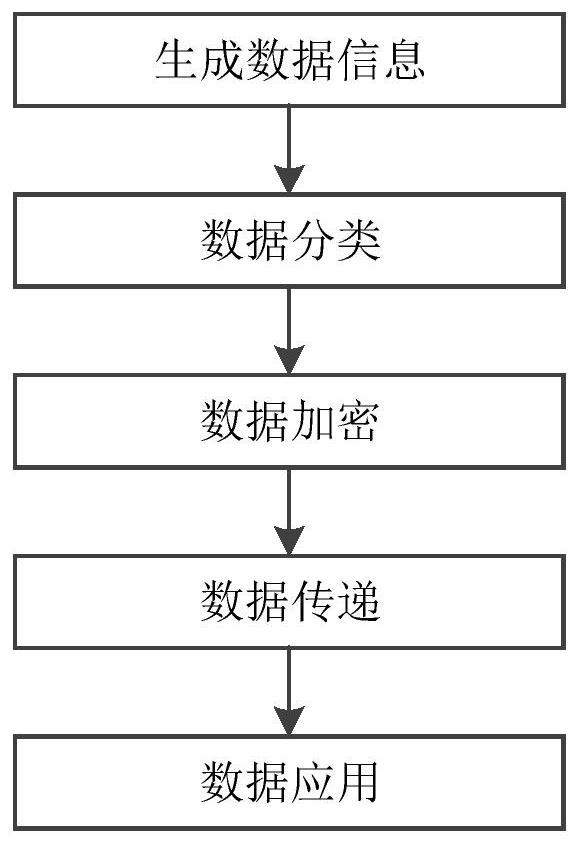

[0082] Such as figure 2 As shown, a method of applying block chain technology to realize the traceability of production line equipment, wherein the method includes the following steps:

[0083] (1) Generate data information: generate various data information of production line equipment through the equipment layer, and store various data information of production line equipment in the database through the equipment management computer;

[0084] (2)) Enter the operation information of each process: write the data of the operation of each process and the use of accessories on the products on the production line to the database;

[0085] (3) Data classification, call the data information in the equipment management computer, classify the data information in the equipment management computer database through the equipment data information classification model, in order to realize the search for the data information of the production line equipment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com