Assembly type highway tunnel crash barrier

A technology for road tunnels and anti-collision guardrails, which is applied to roads, roads, road safety devices, etc., can solve problems such as inability to buffer vehicles, and achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

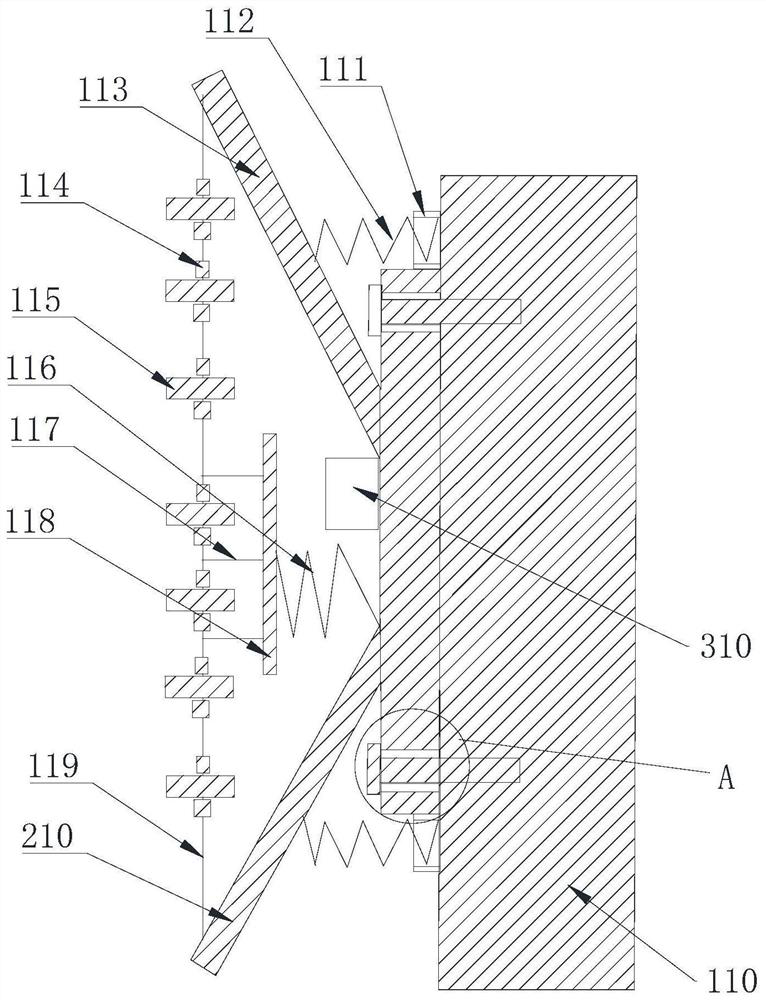

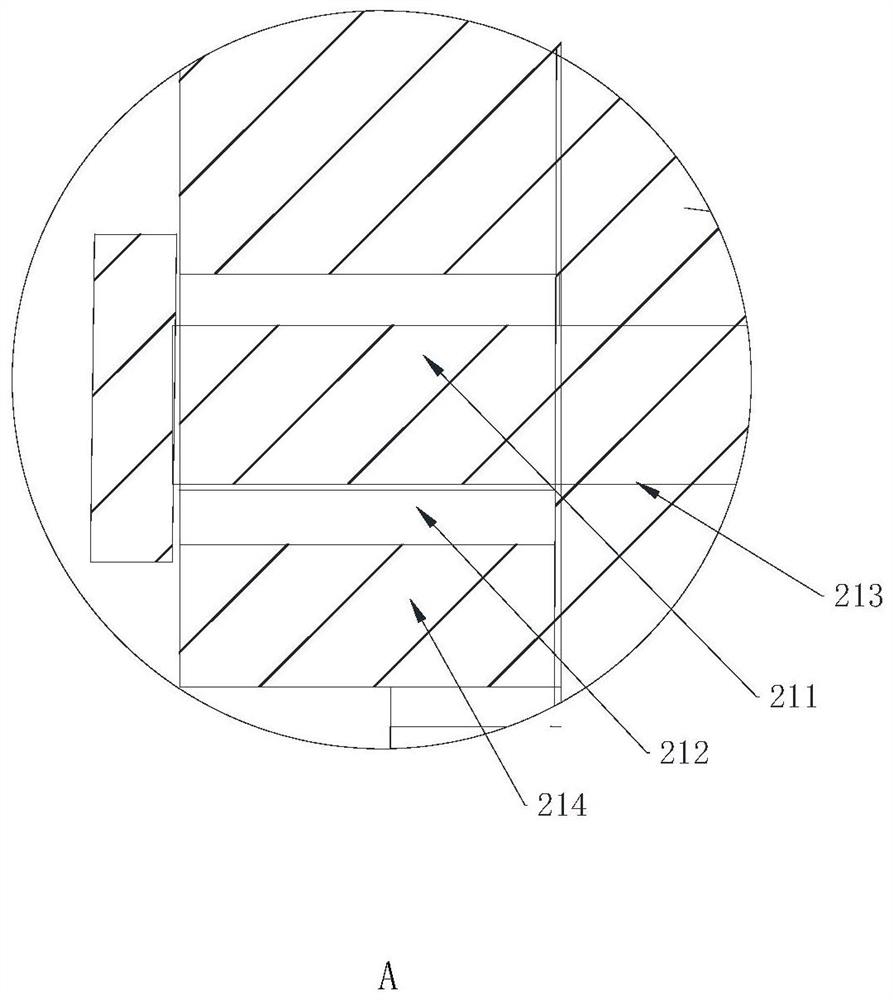

[0026] The embodiment will be further described with reference to the accompanying drawings.

[0027] The words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions indicated in the accompanying drawings, and the words " "Bottom" and "top", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

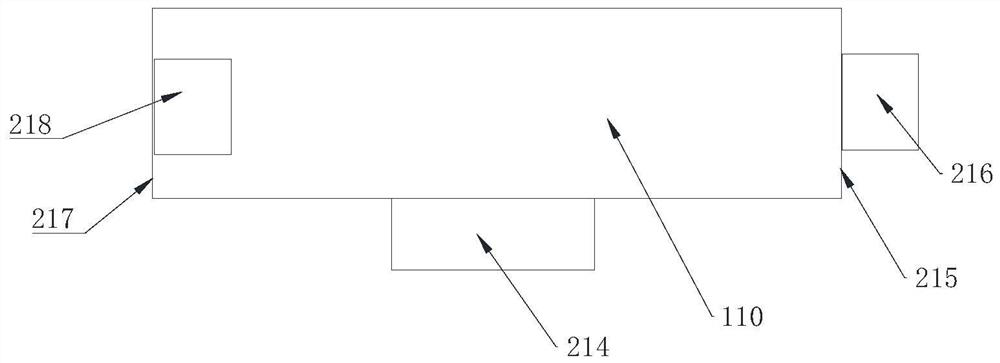

[0028] A prefabricated road tunnel anti-collision guardrail, refer to figure 1 and image 3 , including the abutment seat 110 and a buffer mechanism located on the abutment seat 110, the abutment seat 110 includes a left side wall 217 and a right side wall 215, a groove 218 is provided on the left side wall 217, and a groove 218 is provided on the right side wall 215 218 matched convex bar 216; the buffer mechanism includes a fixed block 214 located on the side wall of the base seat 110, and the fixed block 214 is symmetrically provided with a strut assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com