Moisture-proof and mildew-proof non-woven fabric and preparation method thereof

A non-woven and anti-mildew technology, applied in the field of non-woven fabrics, can solve the problems of shortening the anti-mildew time, adjusting the release speed of the anti-mildew agent, low anti-mildew ability, etc. release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

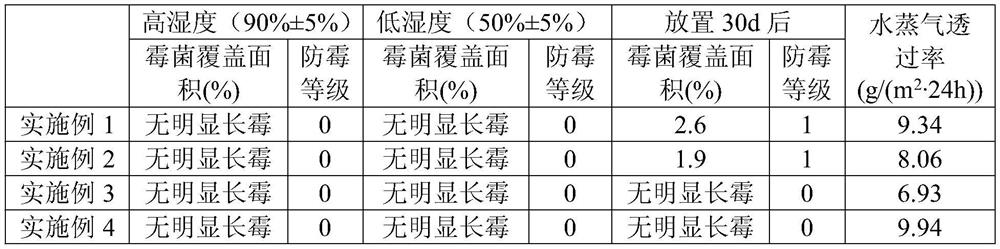

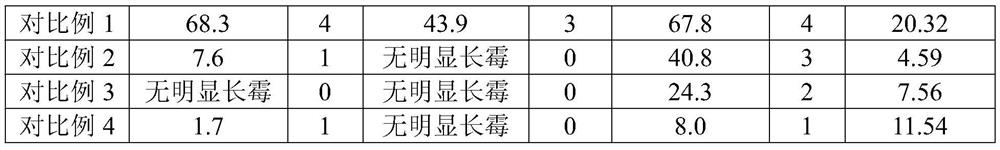

Examples

Embodiment 1

[0037] A moisture-proof and mildew-proof non-woven fabric, comprising the following raw materials: cellulose fiber, carboxymethyl cellulose fiber, camphor tree essential oil / calcined shell powder@modified hydroxyapatite particles; the cellulose fiber and carboxymethyl cellulose The mass ratio of fibers is 3:1; the amount of camphor tree essential oil / calcined shell powder@modified hydroxyapatite particles is 5% of the total mass of cellulose fibers and carboxymethyl cellulose fibers.

[0038] The preparation method of the above-mentioned camphor tree essential oil / calcined shell powder@modified hydroxyapatite particles is as follows:

[0039] (1) be that shell powder (average particle diameter is 50 μ m) and nano-hydroxyapatite (average particle diameter is 50nm) that mass ratio is 1:0.4 is placed in high-speed mixer, mixes to material temperature at a high speed under 500r / min Raise to 80°C to produce shell powder@hydroxyapatite particles;

[0040] (II) Put the shell powder ...

Embodiment 2

[0047] A moisture-proof and mildew-proof non-woven fabric, comprising the following raw materials: cellulose fiber, carboxymethyl cellulose fiber, camphor tree essential oil / calcined shell powder@modified hydroxyapatite particles; the cellulose fiber and carboxymethyl cellulose The mass ratio of fibers is 2:1; the amount of camphor tree essential oil / calcined shell powder@modified hydroxyapatite particles is 8% of the total mass of cellulose fibers and carboxymethyl cellulose fibers.

[0048] The preparation method of the above-mentioned camphor tree essential oil / calcined shell powder@modified hydroxyapatite particles is as follows:

[0049] (1) be that shell powder (average particle diameter is 100 μm) and nano-hydroxyapatite (average particle diameter is 150nm) that mass ratio is 1:0.5 is placed in high-speed mixer, mixes to material temperature at high speed under 650r / min Raise to 90°C to produce shell powder@hydroxyapatite particles;

[0050] (II) Put the shell powder@h...

Embodiment 3

[0057] A moisture-proof and mildew-proof non-woven fabric, comprising the following raw materials: cellulose fiber, carboxymethyl cellulose fiber, camphor tree essential oil / calcined shell powder@modified hydroxyapatite particles; the cellulose fiber and carboxymethyl cellulose The mass ratio of fibers is 1:1; the amount of camphor tree essential oil / calcined shell powder@modified hydroxyapatite particles is 10% of the total mass of cellulose fibers and carboxymethyl cellulose fibers.

[0058] The preparation method of the above-mentioned camphor tree essential oil / calcined shell powder@modified hydroxyapatite particles is as follows:

[0059] (1) be that shell powder (average particle diameter is 200 μ m) and nano-hydroxyapatite (average particle diameter is 250nm) that mass ratio is 1:0.6 is placed in high-speed mixer, mixes to material temperature at a high speed under 800r / min Raise to 100°C to produce shell powder@hydroxyapatite particles;

[0060] (II) Put the shell pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com