Refining process of oligomeric dextran and production process prediction method

A technology of dextran and process, which is applied in the field of refining process and production process prediction of oligomeric dextran, and can solve problems such as difficult to achieve oligosaccharide retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

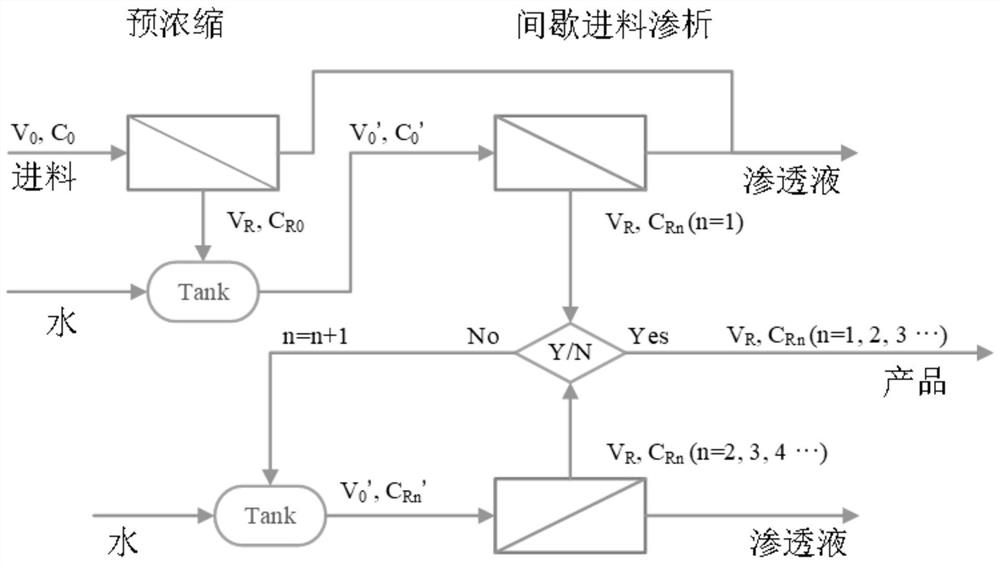

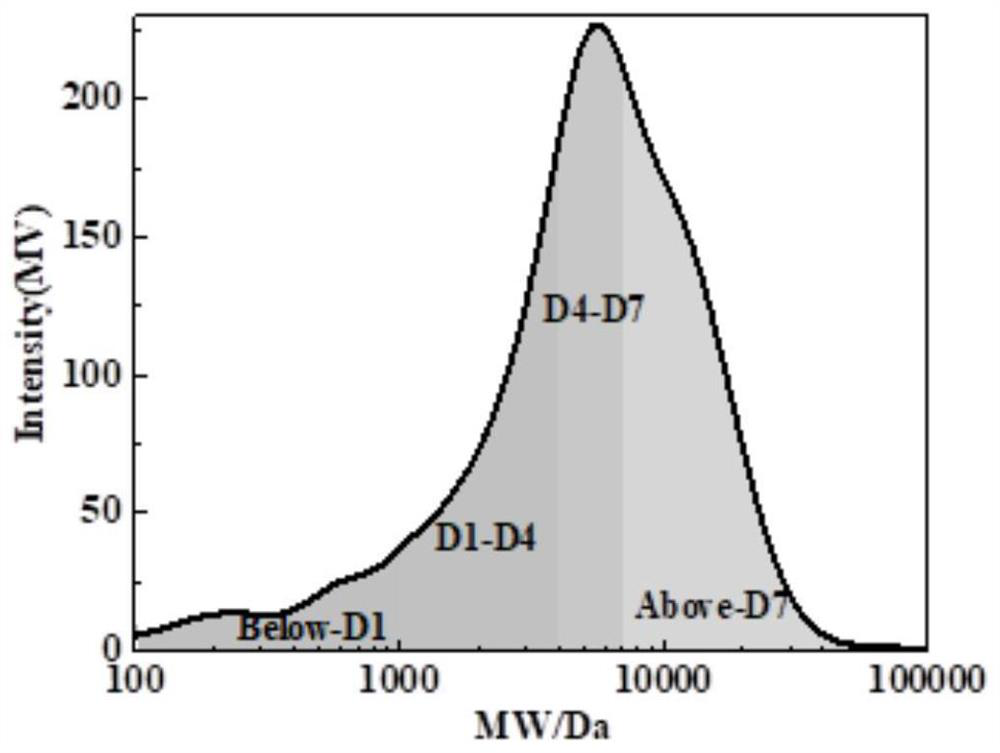

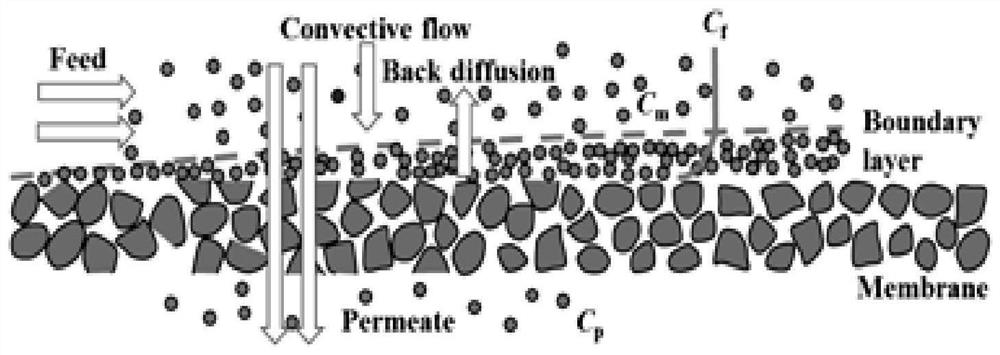

[0050] Due to the prebiotic properties of oligosaccharides and their role in healthcare, it is urgent to separate and purify oligosaccharides from complex solutions. The present invention systematically studies the diafiltration process of oligomeric dextran refining, and then extends the theoretical model. Using intermittent feed diafiltration, through the small pore size ZrO with narrow pore size distribution 2Ceramic ultrafiltration membrane narrows the molecular weight distribution of oligodextran. The production efficiency is involved in the intermittent diafiltration process. Under different diafiltration operations, the production efficiency varies greatly. It is particularly important to establish a batch diafiltration model to realize the prediction and optimization of the membrane process. Based on mass balance and concentration polarization models, a model considering the variation of solute rejection with concentration was developed to describe the process. The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mwco | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com