Separation device and separation method for removing silicon tetrachloride in organosilicon monomer azeotrope

A silicon tetrachloride and separation device technology, applied in organic chemistry, silicon organic compounds, chemical instruments and methods, etc., can solve the problems of small boiling point gap, product purity not meeting the expected requirements, equipment and pipeline blockage, etc. Achieve the effects of improving purity, reducing cooling water and steam consumption, and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

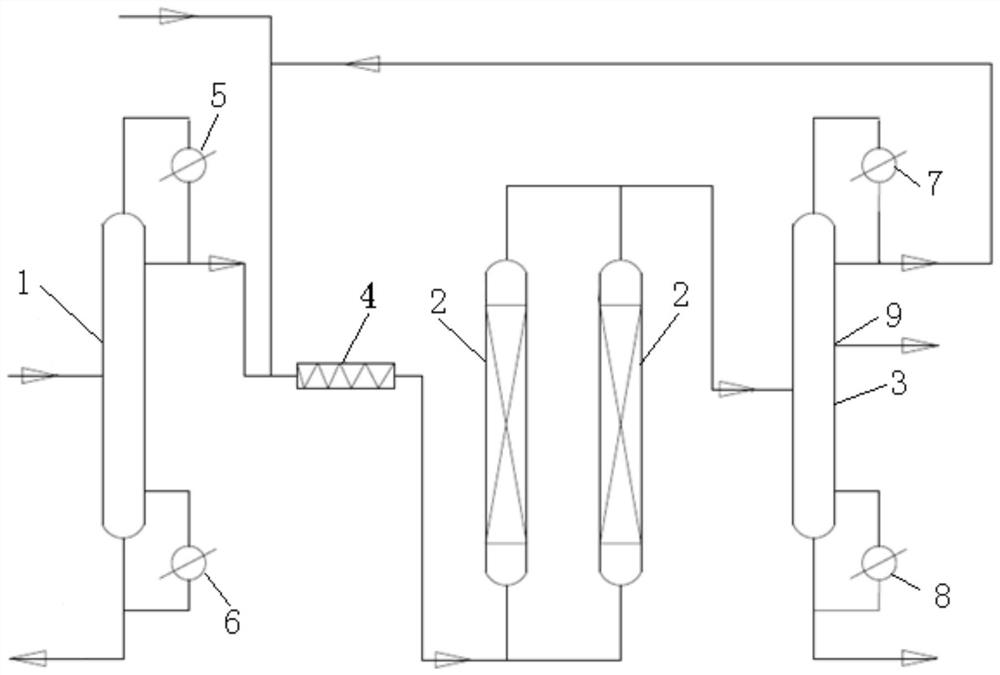

[0031] This embodiment provides a separation device for removing silicon tetrachloride from the azeotrope of organosilicon monomer, and directly synthesizes methylchlorosilane monomer to obtain the crude product of methylchlorosilane monomer, methylchlorosilane monomer The crude product undergoes primary rectification to remove high boilers and low boilers to obtain organosilicon monomer azeotropes, which include: trimethylchlorosilane and silicon tetrachloride. The separation device include:

[0032] The first separation tower is used to separate the organosilicon monomer azeotrope, obtain the dimethyl dichlorosilane product at the bottom of the first separation tower, and obtain the tower of the first separation tower at the top of the first separation tower Top material, the top material of the first separation tower comprises silicon tetrachloride;

[0033] The fixed bed reactor is connected with the top of the first separation tower, and the inlet of the fixed bed reacto...

Embodiment 2

[0041] Such as figure 1 As shown, this embodiment provides a separation device for removing silicon tetrachloride in the azeotrope of organosilicon monomers, and directly synthesizes methylchlorosilane monomers to obtain the crude product of methylchlorosilane monomers, methyl chloride The crude product of silane monomer is separated by primary rectification to remove high boilers and low boilers to obtain organosilicon monomer azeotrope. The organosilicon monomer azeotrope mainly includes: trimethylchlorosilane, silicon tetrachloride , the separation device includes:

[0042] The first separation tower 1 is used to separate the organosilicon monomer azeotrope, and the dimethyldichlorosilane product with a content greater than 99mas% is obtained in the tower still of the first separation tower 1, and in the tower of the first separation tower 1 Top obtains the tower overhead material of the first separating tower 1, and the tower overhead material of the first separating towe...

Embodiment 3

[0061]The boiling point of trimethylchlorosilane: 57.9°C, 101KPa; the boiling point of silicon tetrachloride is 57.6°C, 101KPa; in the prior art, the mixture of these two substances cannot be effectively separated by general rectification. The crude product of methyl chlorosilane monomer synthesized by the direct method is sent to the first-stage height removal tower to remove high-boiling multi-component compounds mainly composed of silicon-silicon bonds and silicon-oxygen-silicon bonds; the top product is condensed Sent to the secondary de-lowering tower, through rectification to remove low-boiling multi-component compounds composed of methyl chloride, silicon tetrachloride, trimethyl monochlorosilane, and monomethyl hydrogen-containing dichlorosilane, and continue to send to the subsequent light Separation is carried out in separate towers; the product obtained in the tower still is sent to the three-stage separation tower, and the tower still obtains a high-purity dimethyld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com