Cone sintering device in optical fiber preform powder preparation and working method

An optical fiber preform and sintering device technology, which is applied to manufacturing tools, glass manufacturing equipment, etc., can solve the problems of frequent tempering, short service life of the device, and lack of disassembly and maintenance, and achieves the effect of improving the adequacy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

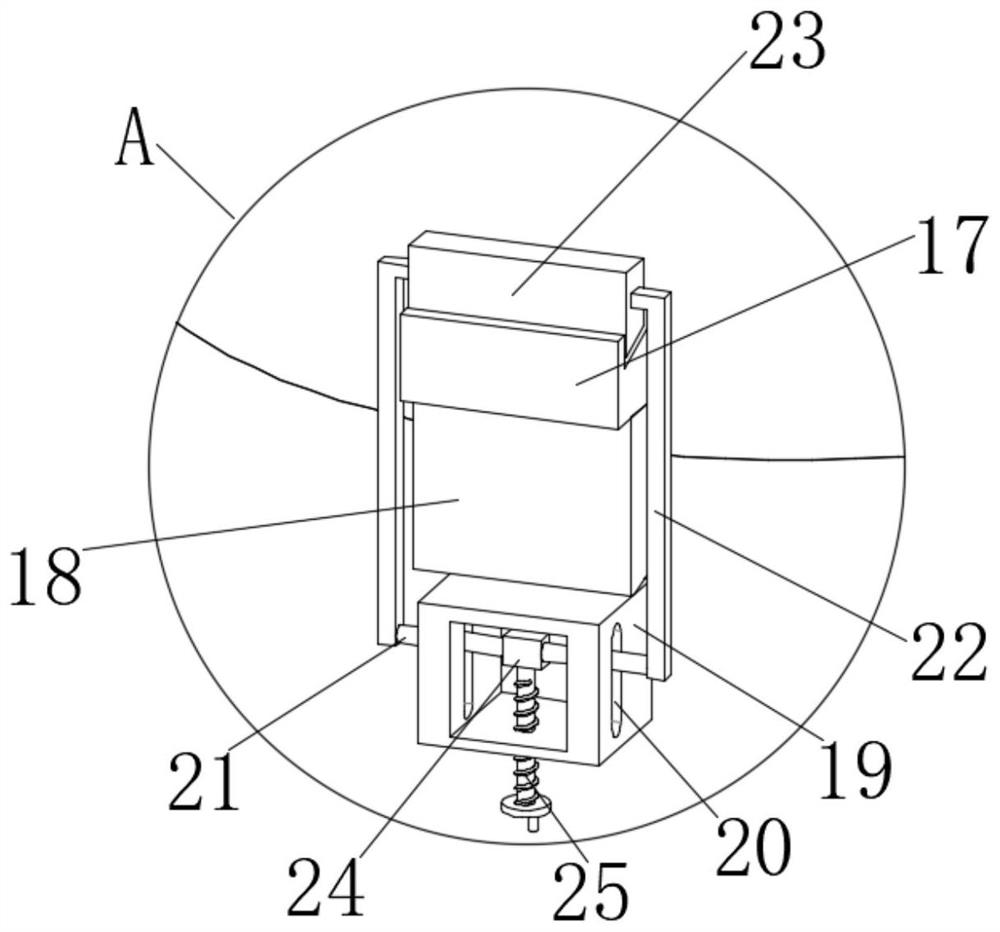

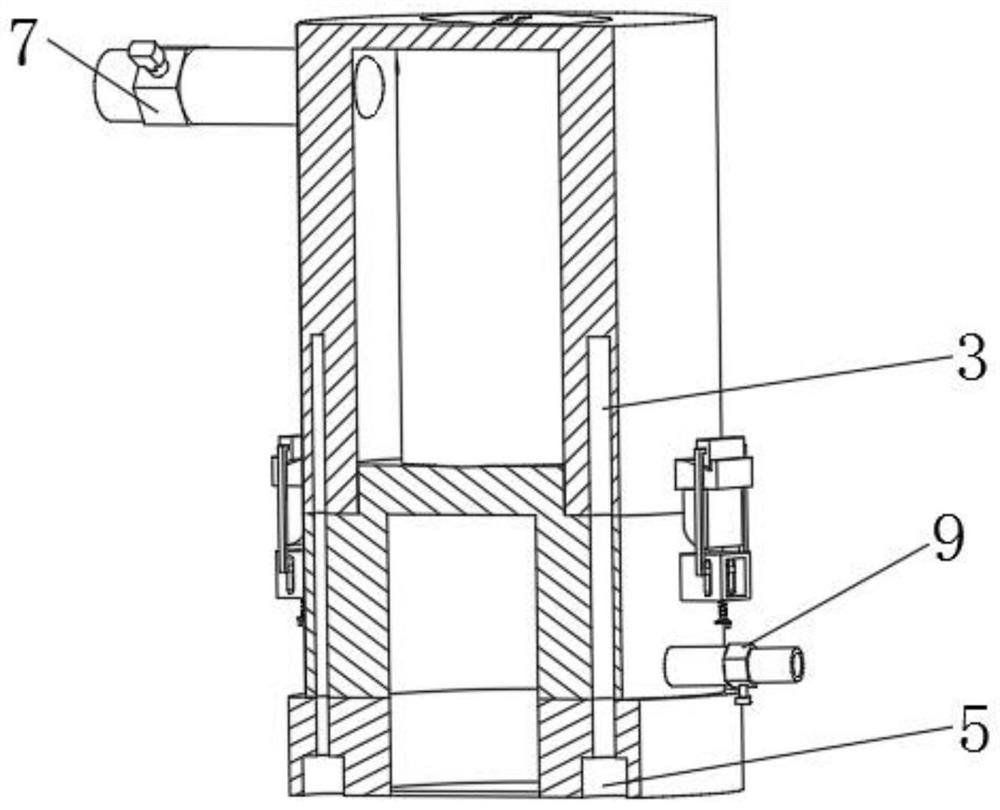

[0024] Please refer to the attached Figure 1-4 , a taper sintering device in the preparation of optical fiber preform powder, comprising a first layer of cylinder 1, a second layer of cylinder 2 and a third layer of cylinder 4, the first layer of cylinder 1 is located in the second layer of cylinder 2, the second layer of cylinder body 2 is located below the third layer of cylinder body 4, the bottom surface of the first layer of cylinder body 1 is provided with a limiting groove 5, and the limiting groove 5 is provided with hexagon socket bolt holes 3 socket bolt holes 3 At the same time, it vertically penetrates the side wall of the first layer of cylinder body 1 and the side wall of the second layer of cylinder body 2 and extends into the side wall of the third layer of cylinder body 4. The number of hexagon socket bolt holes 3 is six, and the number of The bottom end of the outer wall of the three-layer cylinder body 4 is fixedly connected with the limit block 17, and the...

Embodiment 2

[0026] Based on Example 1, as attached Figure 1-4 , the third layer of cylinder body 4 is socketed on the surface of the second layer of cylinder body 2, a combustion-supporting gas chamber 10 is formed between the second layer of cylinder body 2 and the third layer of cylinder body 4, and the inside of the second layer of cylinder body 2 is gas Mixing chamber 12, the top wall of the second layer cylinder 2 is provided with several through holes 11, the through holes 11 run through the top wall of the second layer cylinder 2 and communicate with the combustion-supporting gas chamber 10, and the top of the gas mixing chamber 12 is opened There are several through holes 14, and the outer wall of the third layer cylinder body 4 is fixedly connected with a gas delivery pipe 16, which runs through the side wall of the third layer cylinder body 4 and communicates with the combustion-supporting gas cavity 10, and the gas delivery pipe 16 is on the A metering valve 17 is fixedly inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com