Two-stage groove type distributing device provided with pressure stabilizing plate and used for thin-layer drying equipment

A thin-layer drying and pressure-stabilizing plate technology, which is used in water distribution pipes, chemical instruments and methods, water/sludge/sewage treatment, etc. problems, to achieve high overall distribution uniformity, avoid temperature unevenness, and achieve the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

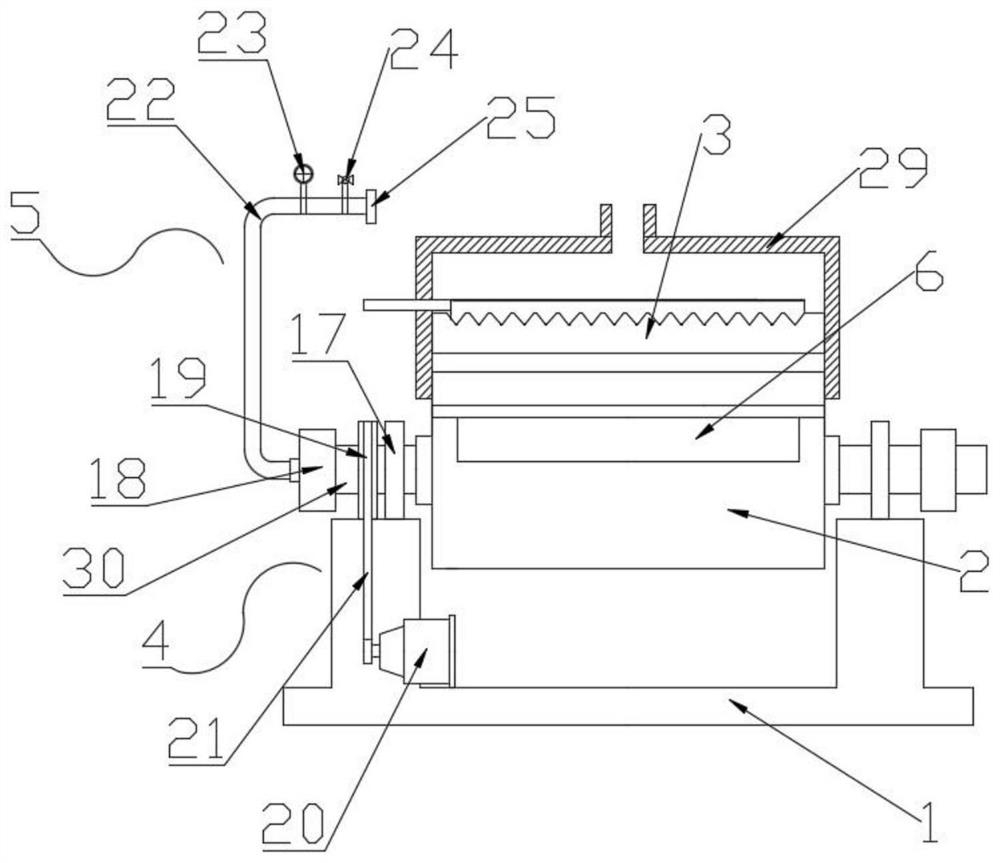

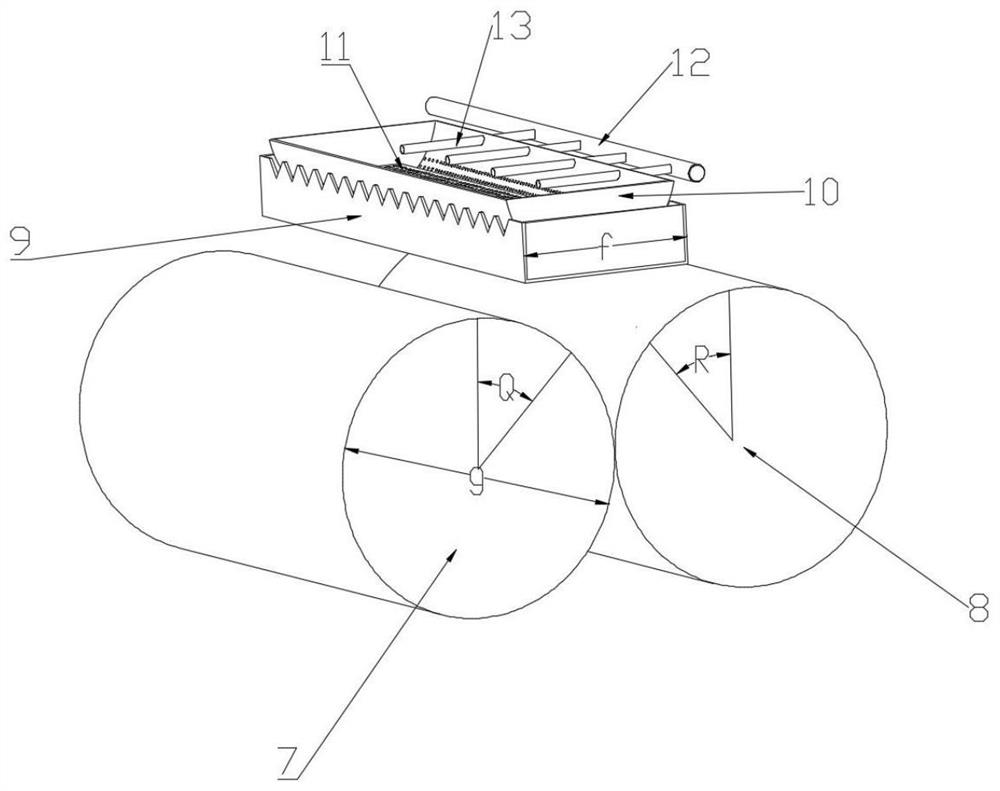

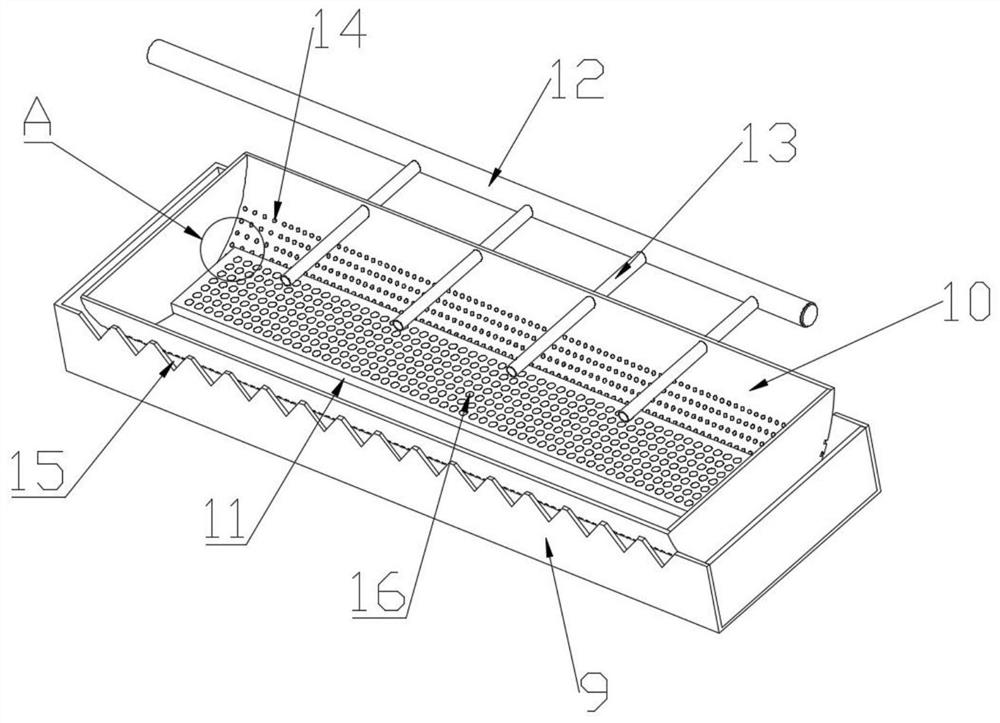

[0040] Embodiment: the present invention provides technical scheme, as figure 1 , a two-stage trough distributor with a pressure stabilizing plate for thin-layer drying equipment, including a support frame 1, a drying rotary column 2 is arranged on the upper end of the support frame 1, and the drying rotary column 2 is a rotating horizontal column structure, and the internal communication Heat conduction oil is used as the carrier when the mother liquor is dried, and it can evenly spread the mother liquor on its outer surface in cooperation with the secondary material distribution mechanism 3. The upper end of the drying rotary column 2 is provided with a secondary material distribution mechanism 3, which is used to The mother liquor is laid on the outer surface of the drying rotary column 2. On the one hand, it slows down the falling kinetic energy of the mother liquor and prevents the secondary material distribution mechanism 3 from being directly impacted by the mother liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com