Nodular cast iron pipe conveying device capable of preventing falling and achieving automatic feeding and discharging

A ductile iron pipe, automatic loading and unloading technology, used in transportation and packaging, load hanging components, cranes, etc., can solve the problems of inconvenient loading and unloading speed, inconvenient loading and unloading, easy to separate from the carriage, etc., to increase stability and reduce jitter , the effect of increasing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

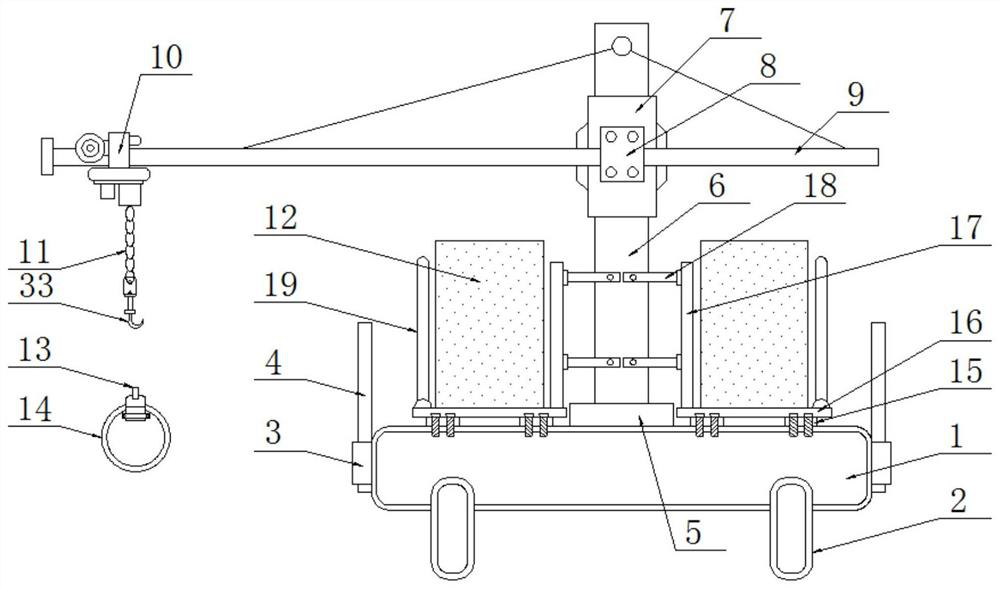

[0026] see Figure 1-6 , a nodular cast iron pipe transportation device that prevents falling and can automatically load and unload materials, including a base 1, a roller 2 is provided at the bottom of the base 1, side sleeves 3 are provided on the left and right sides of the base 1, and the side sleeves 3 The sleeve rod 4 is arranged inside, and the sleeve rod 4 can move up and down in the side sleeve 3. The side plate is between the front and rear two sets of sleeve rods 4. When unloading, the sleeve rod 4 is moved downward to make the side plate move down, which is convenient For unloading, a reinforced steel plate 5 is set at the center of the top of the base 1, and the reinforced steel plate 5 is welded on the base 1, and a pillar 6 is arranged on the reinforced steel plate 5, and the pillar sleeve 7 is sleeved on the pillar 6, and the pillar sleeve 7 can rotate, and the pillar sleeve 7 Suspender 9 is set on the front end face of the suspension rod 9, and the suspension ...

Embodiment 2

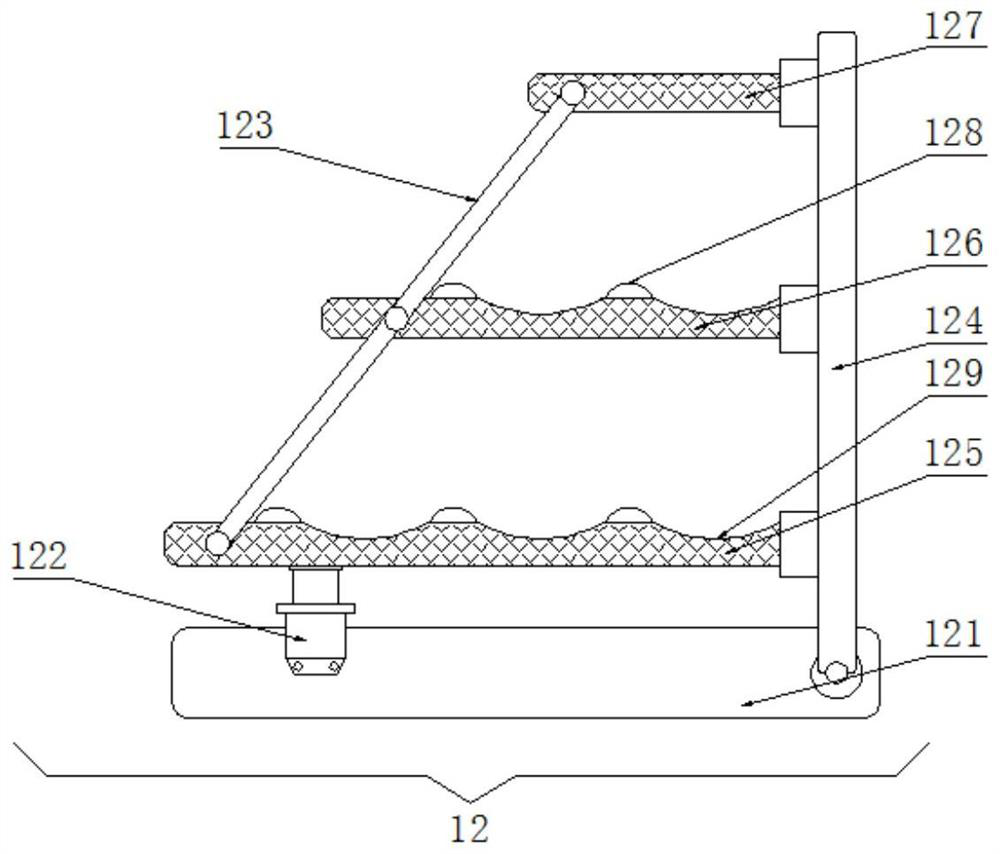

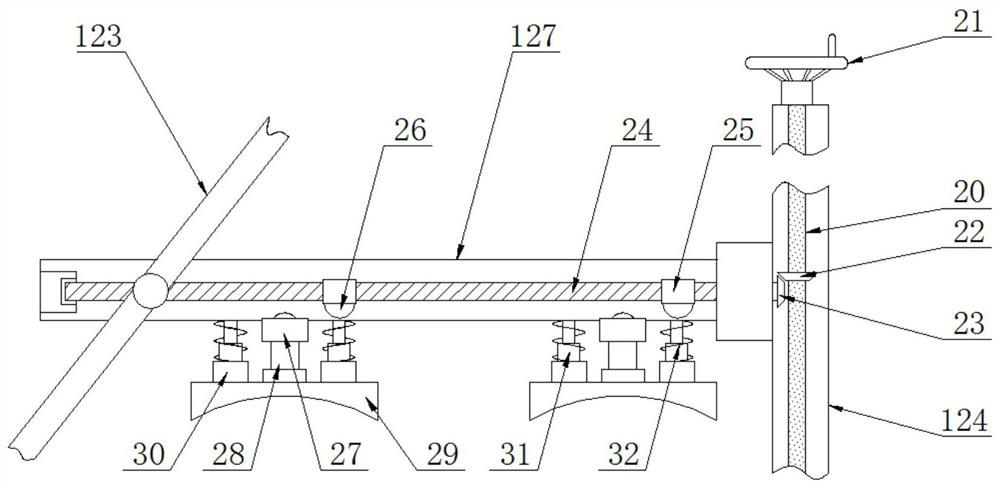

[0036] Such as image 3 As shown, there is a through hole in the baffle plate 124, and the driving shaft 20 is arranged in it. The driving shaft 20 is placed vertically up and down. The top of the driving shaft 20 is coaxially connected with the hand wheel 21. The driving bevel gear 22, the driving bevel gear 22 meshes with the driven bevel gear 23, the driven bevel gear 23 is connected with the screw mandrel 24, the screw mandrels 24 are placed horizontally, and the joints of the screw mandrels and the horizontal plates are all provided with bearings, the screw mandrels 24 Fixed in the second horizontal plate 126 and the third horizontal plate 127, the threaded slider 25 is evenly sleeved on the screw rod 24, and the bottom end of the threaded slider 25 is fixedly connected with the first extruding block 26, and the first extruding block 26 is Semicircle, the bottom of the second transverse plate 126 and the third transverse plate 127 has a through hole, the limit sleeve 27 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com