Multi-station spoke steel plate feeding system

A multi-station, steel plate technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low degree of automation, achieve the effects of reducing labor intensity, uniform feeding, and guaranteed output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

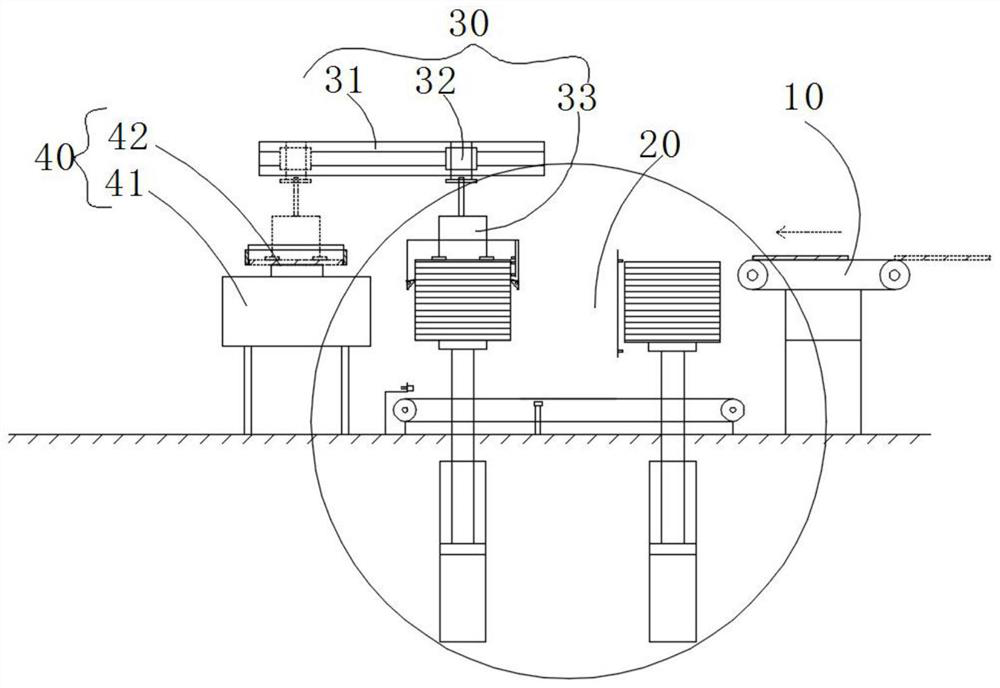

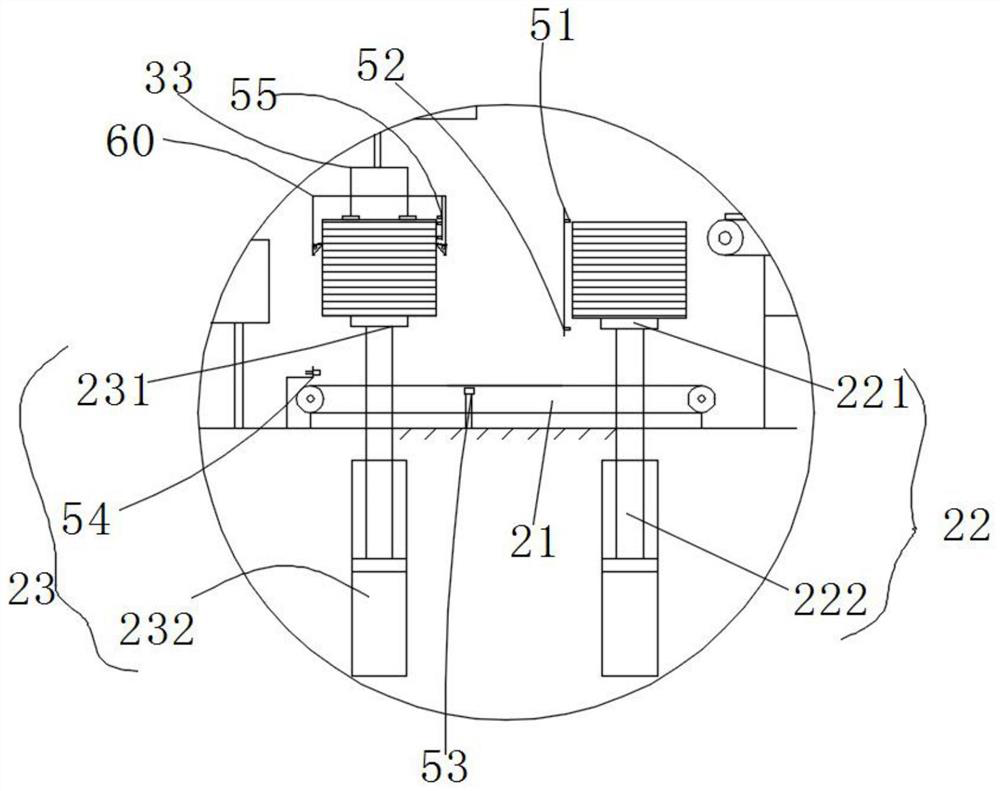

[0022] A multi-station spoke steel plate feeding system, see figure 1 , including a feeding mechanism 10, a storage mechanism 20, a handling mechanism 30, a positioning mechanism 40 and a transfer mechanism arranged in sequence, wherein the feeding mechanism 10 is used to transport a single piece of spoke steel; spoke steel plates, and superimpose the single spoke steel plates one by one; the transport mechanism 30 is used to transport the spoke steel plates stacked on the storage mechanism 20 one by one, and transport the spoke steel plates to the positioning mechanism 40 one by one; the positioning mechanism 40 is used for each spoke. The steel plate is repositioned to meet the preset requirements; the positioned spoke steel plate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com