Nasal cavity filler for hemostasis and manufacturing method of nasal cavity filler

A production method and filler technology, applied in the field of medical devices, can solve problems such as poor comfort and poor hemostatic effect, and achieve the effects of increasing elasticity, increasing ventilation performance, and improving ventilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

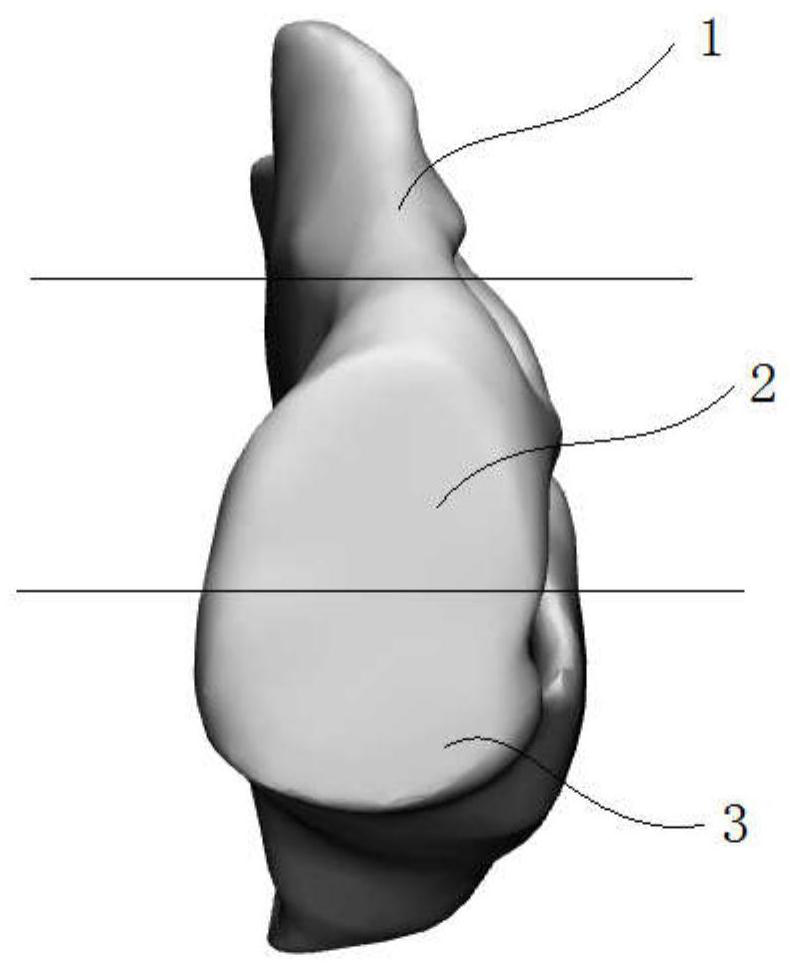

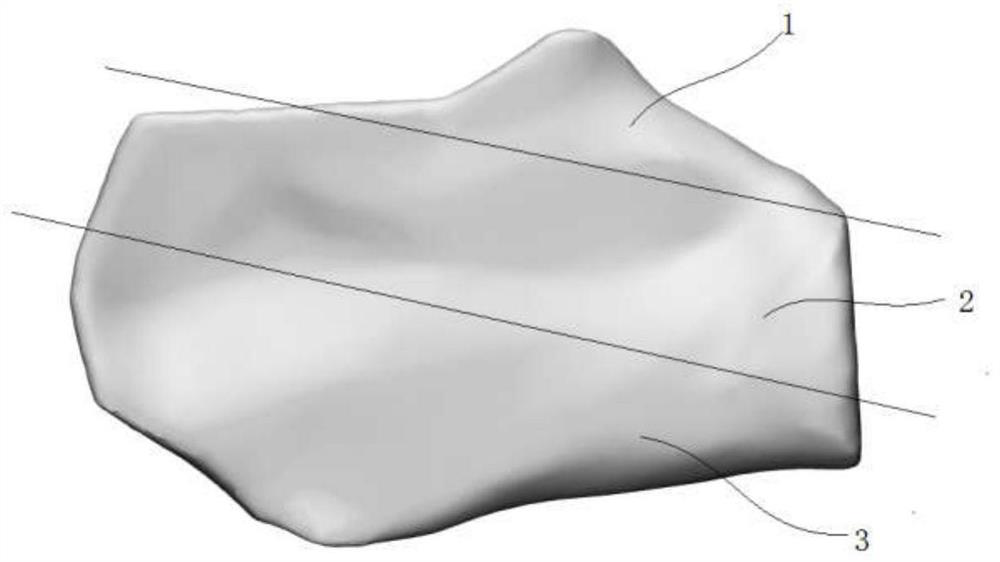

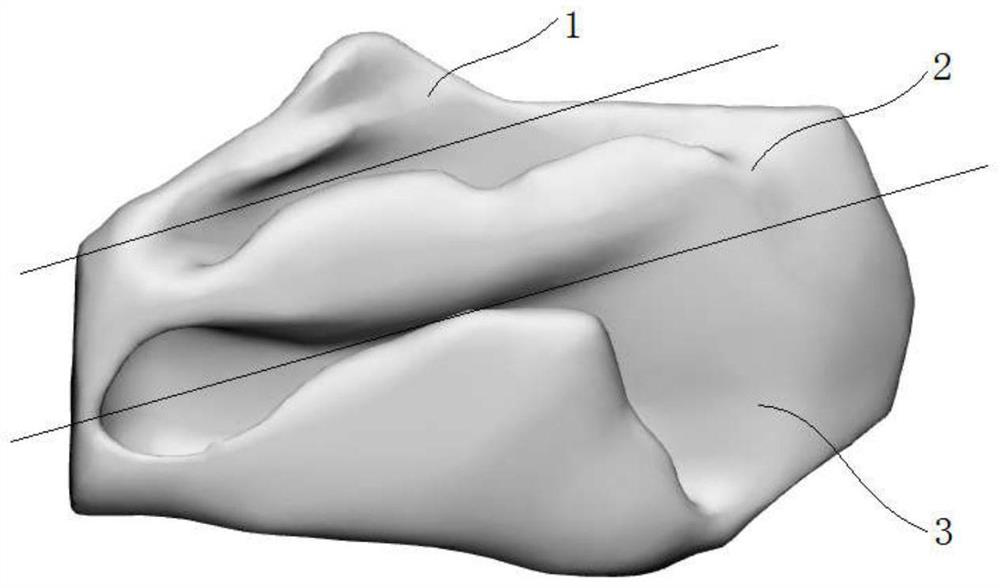

[0054] A nasal filling, comprising a filling body, such as Figure 1-Figure 3As shown, the filler body is an elastic part that is proportionally reduced according to the shape of the nasal cavity; the filler body absorbs liquid and can expand; after expansion, the filler body is an elastic part that is enlarged proportionally to the shape of the nasal cavity.

[0055] The filler body includes at least one of the upper nasal passage filling assembly 1, the middle nasal passage filling assembly 2, and the lower nasal passage filling assembly 3;

[0056] The upper nasal passage filling assembly 1 matches the upper nasal passage; the middle nasal passage filling assembly 2 matches the middle nasal passage; the lower nasal passage filling assembly 3 matches the lower nasal passage.

[0057] By dividing the filling body into three different filling components, the filling components of the corresponding parts are selected for patients with different operations. Parts that do not re...

Embodiment 2

[0070] Mix and foam the materials with the following proportions as filling materials.

[0071] Filling material: polyvinyl alcohol: 80-99%; chitosan: 0-20%; alginate: 0-5%; gelatin: 0-10%;

[0072] The crosslinking agent is formaldehyde solution, the catalyst is concentrated hydrochloric acid, the stabilizer is sodium lauryl sulfate, and the foaming agent is water-soluble starch.

[0073] In this example, polyvinyl alcohol is used as the filling material. Taking 15g of PVA as an example, take 15g of PVA (polyvinyl alcohol) as the raw material, add 75mL of water, stir until completely dissolved, then add 15mL of formaldehyde solution (crosslinking agent) and 2.5mL of Mass fraction 30% concentrated hydrochloric acid (catalyst), react for about 5 minutes, then add 2.5g water-soluble starch (foaming agent) and 1.5g sodium lauryl sulfate (stabilizer), react at constant temperature for 30 minutes, and keep stirring during the reaction. After the foam is stable, let it rest to room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com