Silicon/perovskite laminated solar cell

A technology of solar cells and perovskite cells, applied in the field of solar cells, can solve problems such as low stability, affecting the life of silicon/perovskite solar cells, short-circuit current decline, etc., and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

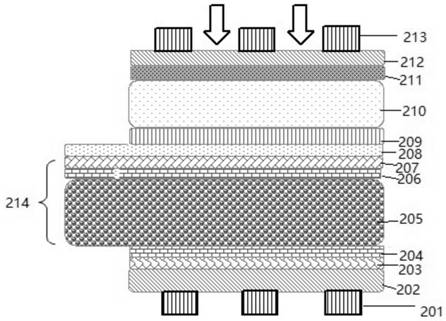

[0074] Example 1: Preparation of silicon / wide bandgap perovskite parallel stack cell

[0075] S1. On the n-type silicon wafer that has been cleaned and textured, each of the two surfaces is coated with an intrinsic amorphous silicon layer with a thickness of 10nm and 12nm by plasma-enhanced chemical vapor deposition; and the thickness of the n-type silicon wafer is A part of one side is reserved as an area for leading out the middle transparent conductive layer;

[0076] S2. Depositing a layer of p-type amorphous silicon with a thickness of 10 nm on the 10 nm thick intrinsic amorphous silicon layer. Depositing a layer of n-type amorphous silicon with a thickness of 15 nm on the 12 nm thick intrinsic amorphous silicon layer;

[0077] S3. Prepare indium tin oxide on the n-type amorphous silicon layer by magnetron sputtering, with a thickness of 100nm, and prepare indium tin oxide on the p-type amorphous silicon layer by magnetron sputtering, with a thickness of 120nm;

[0078]...

Embodiment 2

[0084] Example 2: Preparation of silicon / narrow bandgap perovskite parallel stack cell (p-side light incident)

[0085] S1. On the n-type silicon wafer that has been cleaned and textured, each of the two surfaces is coated with an intrinsic amorphous silicon layer by plasma-enhanced chemical vapor deposition, with a thickness of 10nm and 12nm respectively;

[0086] S2. Depositing a layer of p-type amorphous silicon with a thickness of 10 nm on the 10 nm thick intrinsic amorphous silicon layer. Depositing a layer of n-type amorphous silicon with a thickness of 15 nm on the 12 nm thick intrinsic amorphous silicon layer;

[0087] S3. Prepare indium tin oxide on the n-type amorphous silicon layer by magnetron sputtering, with a thickness of 100nm, and prepare indium tin oxide on the p-type amorphous silicon layer by magnetron sputtering, with a thickness of 120nm;

[0088] S4. Depositing a layer of nickel oxide by electron beam on the indium tin oxide layer of the p-type amorphou...

Embodiment 3

[0093] Example 3: Preparation of silicon / narrow bandgap perovskite parallel stack cell (n-side light incident)

[0094] S1. On the n-type silicon wafer that has been cleaned and textured, each of the two surfaces is coated with an intrinsic amorphous silicon layer by plasma-enhanced chemical vapor deposition, with a thickness of 10nm and 12nm respectively;

[0095] S2. Depositing a layer of p-type amorphous silicon with a thickness of 10 nm on the 10 nm thick intrinsic amorphous silicon layer. Depositing a layer of n-type amorphous silicon with a thickness of 15 nm on the 12 nm thick intrinsic amorphous silicon layer;

[0096] S3. Prepare indium tin oxide on the p-type amorphous silicon layer by magnetron sputtering, with a thickness of 100nm, and prepare indium tin oxide on the n-type amorphous silicon layer by magnetron sputtering, with a thickness of 120nm;

[0097] S4. Depositing a layer of tin oxide by electron beam on the indium tin oxide layer of the n-type amorphous s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com