Additive manufacturing excess weld metal prediction method based on molten pool image and deep residual network

A prediction method and molten pool technology, applied in the field of image processing, can solve the problem of difficulty in monitoring the penetration depth of the additive process, and achieve the effect of facilitating real-time control and welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

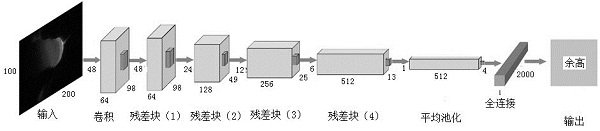

Method used

Image

Examples

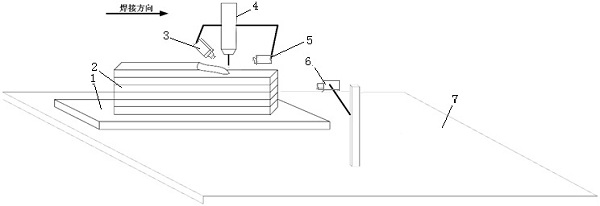

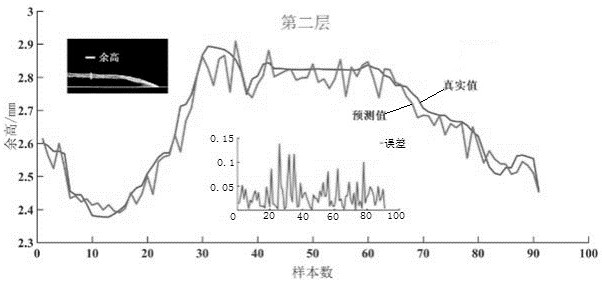

Embodiment 1

[0049] This embodiment is based on the cold metal transition method, that is, the CMT single-pass multi-layer additive manufacturing of stainless steel as the background, and monitors the change of the cladding layer residual height in the arc additive manufacturing process. The process is monofilament CMT, the welding current is 130A, the welding speed is 5mm / s, and the shielding gas is argon-oxygen mixed gas (98.5%Ar 2 +1.5%O 2 ), the gas flow rate is 25L / min, the welding length is 80mm, the number of welding layers is 10, the height of the welding torch 4 is 1mm, the welding wire grade is ER316L, the base material is 304 stainless steel, the camera acquisition frequency is 1000Hz, and the exposure time is 100us. CMT is a special MIG / MAG welding. When the droplet is short-circuited, the welder receives a short-circuit signal, cuts off the welding power supply, and draws back the welding wire to help the droplet fall off and realize the cold transfer of the droplet. This hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com