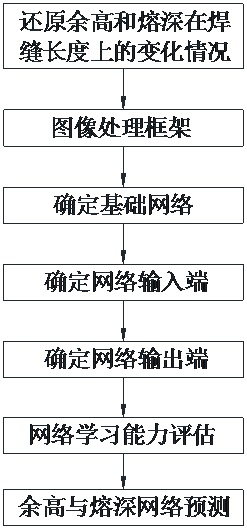

Excess weld metal and weld penetration collaborative prediction method based on molten pool image and deep residual error network

A prediction method and molten pool technology, applied in the field of image analysis, can solve problems such as the decline in the ability of the weld to withstand dynamic loads, and achieve the effect of real-time control of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

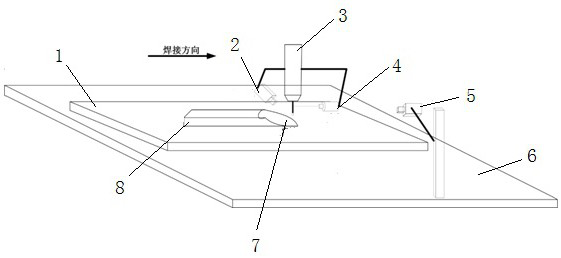

[0045] The experimental data acquisition device for reinforcement and penetration depth of the present invention is a CMT welding experimental platform. CMT welding experiment platform is mainly composed of welding power supply, mobile robot and vision sensor system. The vision system sensor system is placed on a flat workbench 6, and the workbench 6 places the motherboard 1 to be welded. The visual sensor system includes a welding torch 3 fixed on the robot. The welding torch 3 faces the motherboard 1. A CCD color camera 2 is also installed on the robot. Its model is Basler acA640-750uc. In order to correspond the collected image of the molten pool 7 to the actual position of the weld 8, a laser 4 is used for auxiliary positioning, and a laser 4 with a center wavelength of 450nm is used to irradiate the upper edge of the welding wire, and a model of Basler ace acA1920 is placed at the same time -155um CCD black and white camera 5 to capture laser points, such as figure 2 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com