In-situ monitoring method for crevice corrosion

A crevice corrosion, in-situ technology, applied in the field of corrosion of metal materials, can solve the problems of little research guidance on crevice corrosion behavior and law, poor reliability of experimental results, etc., and achieve accurate and reliable experimental results, convenient operation, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for in-situ monitoring of crevice corrosion of the present invention comprises the following steps:

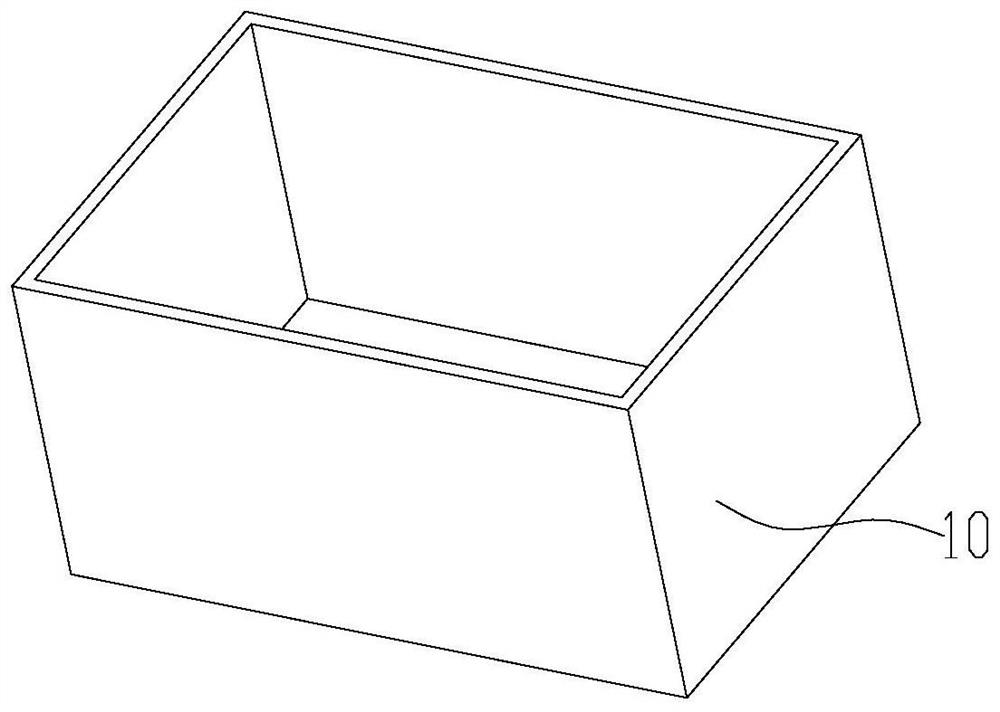

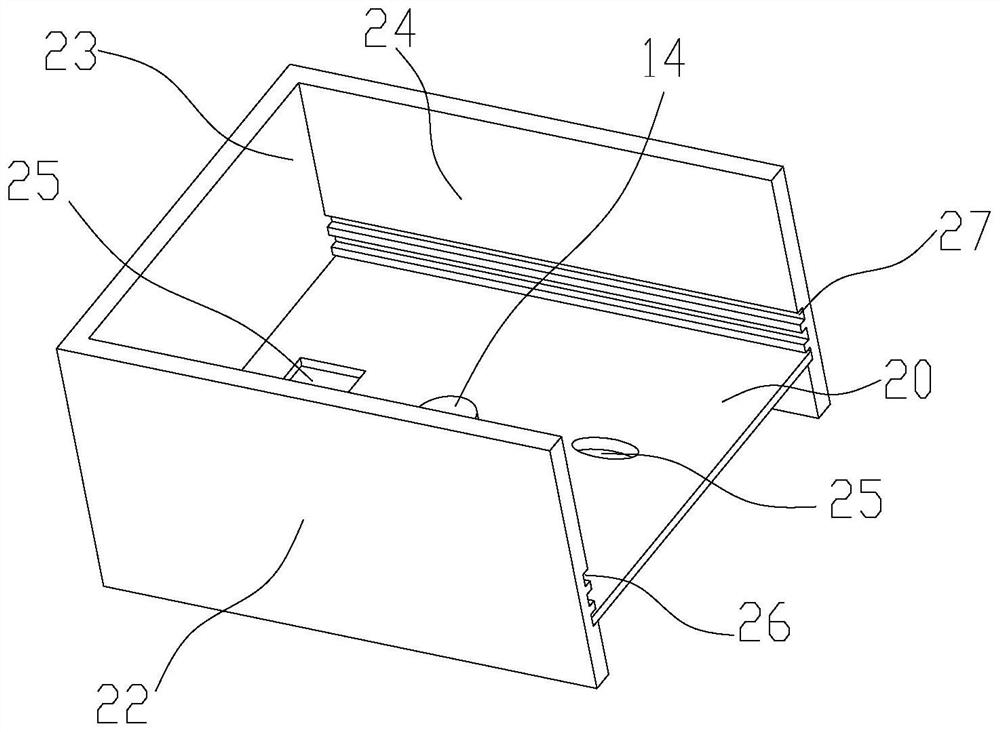

[0039] 1) See attached figure 1 , take the tank body 10, the tank body 10 is a transparent tank body 10, the top of the tank body 10 has an open end, the tank body 10 includes a front plate, a rear plate, a left plate, a right plate and a flat plate, and the flat plate is located at the bottom to form a tank body The bottom wall of 10, the front plate, the right plate, the rear plate and the left plate are connected in sequence to form the peripheral wall of the tank body 10, and the entire tank body 10 is a structure with a cavity inside;

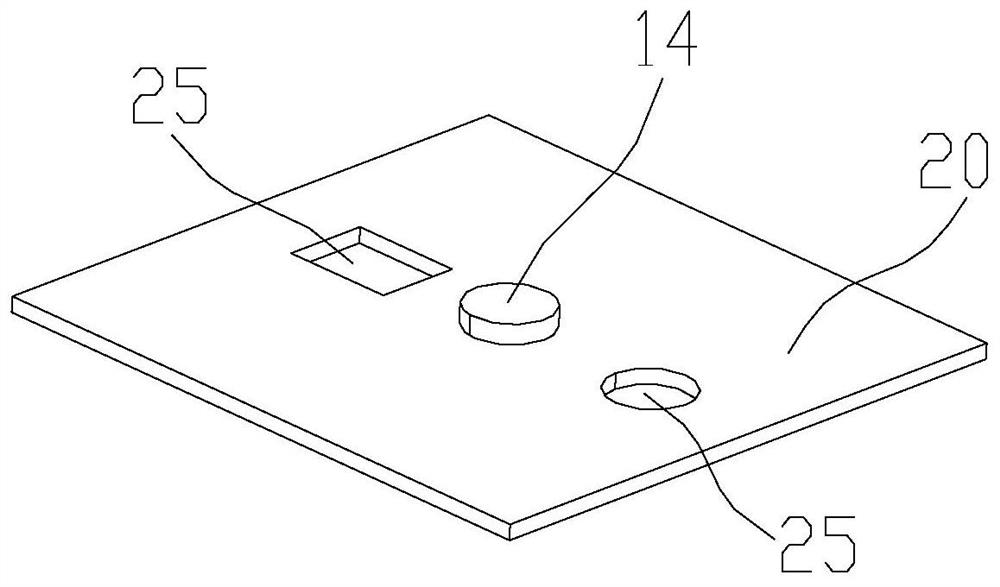

[0040] 2) See attached figure 2 , take the bottom plate 20, open three through holes 25 on the bottom plate 20, among the three through holes 25, one through hole 25 is rectangular, and the other two through holes 25 are circular; the working electrode 14 is installed on the bottom plate 20 in the middle through hole 25;...

Embodiment 2

[0058] In this embodiment, on the basis of the first embodiment, step 8) is adjusted, and the vertical adjustment handle is rotated in the opposite direction, so that the vertical sliding block 41 slides upward along the surface of the vertical sliding rail 42, so that the vertical sliding block 41 passes through The folded plate 36 on the cover plate seat 31 moves upward along the vertical direction with the cover plate seat 31 and the cover plate 30 on it. The sliding column 53 on the horizontal moving mechanism 50 moves upward, and the upward displacement of the cover plate 30 is read as 50 μm through the vertical scale line on the vertical adjustment rod and the vertical alignment line on the vertical adjustment handle, that is, the cover plate 30 and the upper surface of the working electrode 14 form the corrosion gap with a width of 50 μm, denoted as H1; start the electrochemical workstation, observe and record the experimental data, and obtain the experimental result.

...

Embodiment 3

[0061] In this embodiment, on the basis of the second embodiment, step 8) is continued to be adjusted, and the vertical adjustment handle is rotated in the opposite direction, so that the vertical slider 41 slides upward along the surface of the vertical slide rail 42, so that the vertical slider 41 moves upward along the vertical direction with the cover plate seat 31 and the cover plate 30 on it through the folding plate 36 on the cover plate seat 31. At the same time, the connecting ring 55 on the right connecting piece of the cover plate 30 is also Move upward along the sliding column 53 on the horizontal moving mechanism 50, and read the upward displacement of the cover plate 30 as 100 μm through the vertical scale line on the vertical adjustment rod and the vertical alignment line on the vertical adjustment handle, that is, The width of the corrosion gap formed on the upper surface of the cover plate 30 and the working electrode 14 is 100 μm, denoted as H2; start the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com