Garbage pyrolysis cyclone incinerator

An incinerator and pyrolysis technology, which is applied to incinerators, combustion methods, combustion types, etc., can solve the problems of large waste slag volume and difficult to clean, air-density garbage is difficult to burn, and it is difficult to achieve the effect of combustion, so as to reduce the difficulty of cleaning slag. , the effect of increasing air content and speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] as attached figure 1 to attach Figure 4 Shown:

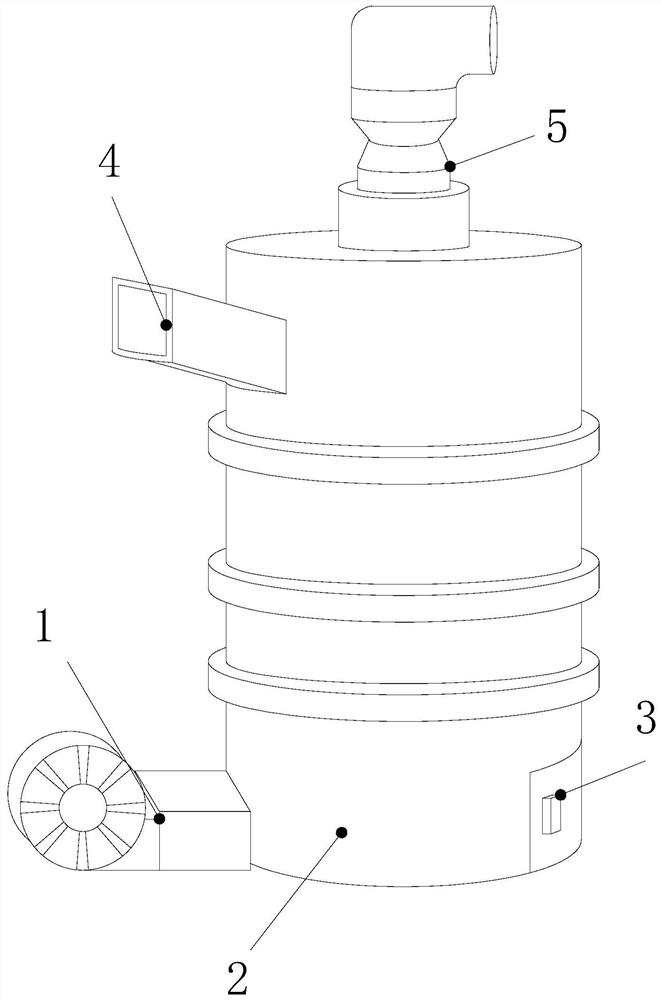

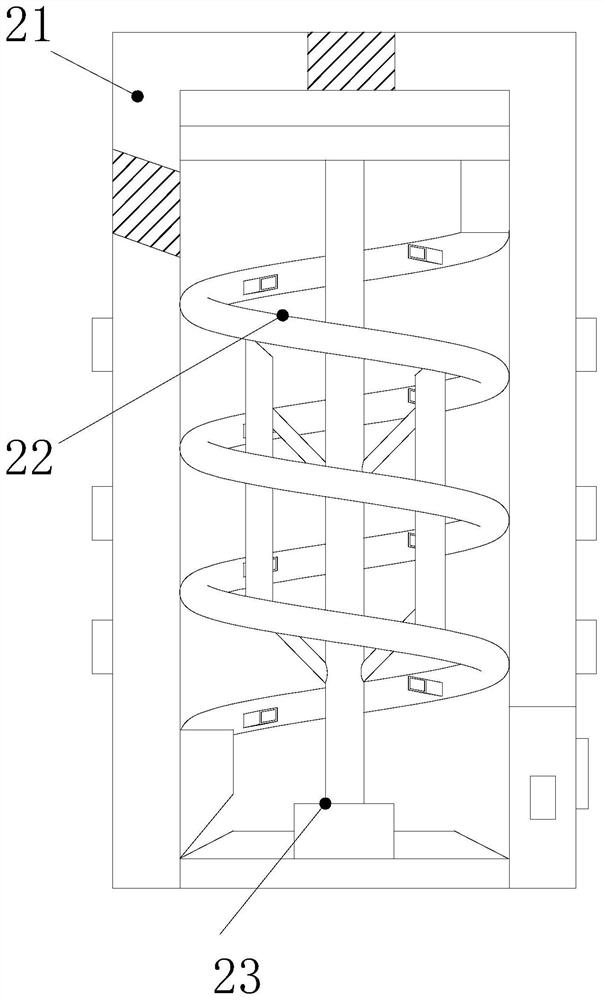

[0025] The invention provides a garbage pyrolysis cyclone incinerator, the structure of which comprises a blower 1, an incineration chamber 2, a cleaning port 3, a feeding port 4, and an exhaust port 5, the blower 1 is connected with the left side bolt of the incineration chamber 2, and the The right side of the incineration chamber 2 is hingedly connected to the outside of the cleaning port 3, the feeding port 4 is embedded and connected to the left side of the upper end of the incineration chamber 2, the exhaust port 5 is screwed to the middle part of the top of the incineration chamber 2, and the incineration chamber 2 includes Outer cover 21, air supply pipe 22, disturbance device 23, the inner side of the outer cover 21 is matched with the outer side of the air supply pipe 22, the air supply pipe 22 is embedded and connected with the right side of the blower 1, and the disturbance device 23 is connected to the inne...

Embodiment 2

[0031] as attached Figure 5 to attach Figure 7 Shown:

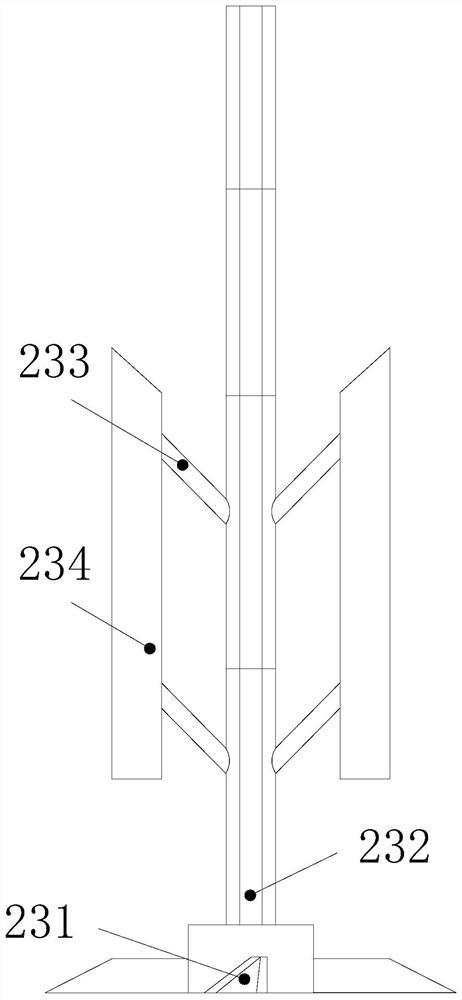

[0032] Wherein, the spoiler rod 232 includes a central block 32a and an expansion plate 32b, the lower end of the central block 32a is movably engaged with the inner side of the middle part of the fixed ring 31d, and the expansion plate 32b is hingedly connected to the upper and lower sides of the central block 32a. The shape of the left and right ends of the central block 32a is fan-shaped, and the upper and lower ends of the central block 32a are arc-shaped hollow structures. The package is helpful to prevent the garbage from falling when the device starts to run and cause jams.

[0033] Wherein, the expansion plate 32b includes a fixed plate b1, a biaxial rod b2, a tension spring b3, an outer flap b4, and a support plate b5, and the fixed plate b1 is embedded and connected with the upper and lower sides of the central block 32a. The biaxial rod b2 is connected between the outer flap b4 and the fixed plate b1. One ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com