A kind of anti-radiation concrete and preparation method thereof

A concrete and anti-radiation technology, applied in the field of concrete, can solve problems such as self-heavy, easy segregation of concrete, poor work performance, etc., and achieve the effects of increased fluidity, increased radiation resistance, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

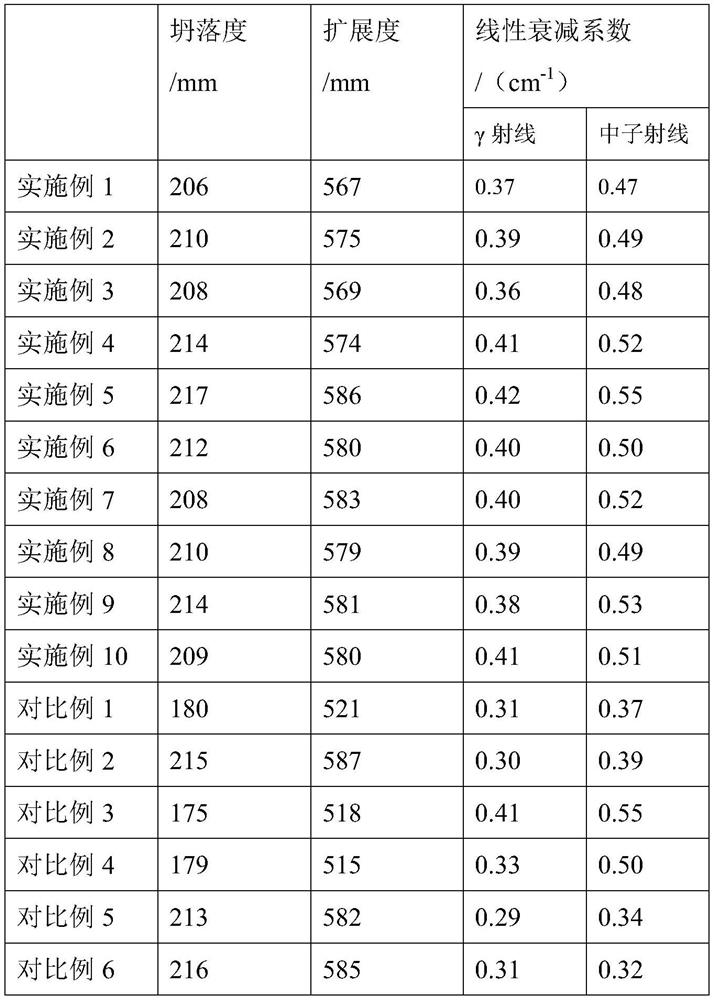

Examples

Embodiment 1

[0046] A kind of anti-radiation concrete, the concrete includes the following components: 350 parts of cement, 150 parts of fly ash, 10 parts of lead powder, 460 parts of coarse aggregate, 650 parts of fine aggregate, 50 parts of bentonite, 8 parts of water reducer, water 180 copies.

[0047] Coarse aggregates include stones, barite, hematite, and lightweight aggregates with a weight ratio of 1:0.5:0.4:0.25, wherein the lightweight aggregates are pumice and volcanic cinders with a weight ratio of 1:1.

[0048] Fine aggregate includes sand, iron ore powder, and boron glass powder in a weight ratio of 1:0.4:0.2.

[0049] The particle size of lead powder is 15-45μm, the particle size of lightweight aggregate is 5-10mm, the stone, barite, and hematite are continuously graded between 5-31.5mm, and the water reducing agent is polycarboxylate water reducing agent. agent.

[0050] A preparation method of radiation-proof concrete comprises the following steps: mixing cement, fly ash,...

Embodiment 2

[0052] The difference with Example 1 is:

[0053] A kind of anti-radiation concrete, the concrete comprises the following components: 370 parts of cement, 135 parts of fly ash, 22 parts of lead powder, 435 parts of coarse aggregate, 675 parts of fine aggregate, 45 parts of bentonite, 8.5 parts of water reducer, water 175 copies.

[0054] The lightweight aggregate is pumice.

Embodiment 3

[0056] The difference with Example 1 is:

[0057] A kind of anti-radiation concrete, the concrete includes the following components: 390 parts of cement, 120 parts of fly ash, 30 parts of lead powder, 400 parts of coarse aggregate, 700 parts of fine aggregate, 40 parts of bentonite, 9 parts of water reducing agent, water 170 copies.

[0058] The lightweight aggregate is pumice, volcanic slag, and ceramsite with a weight ratio of 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com